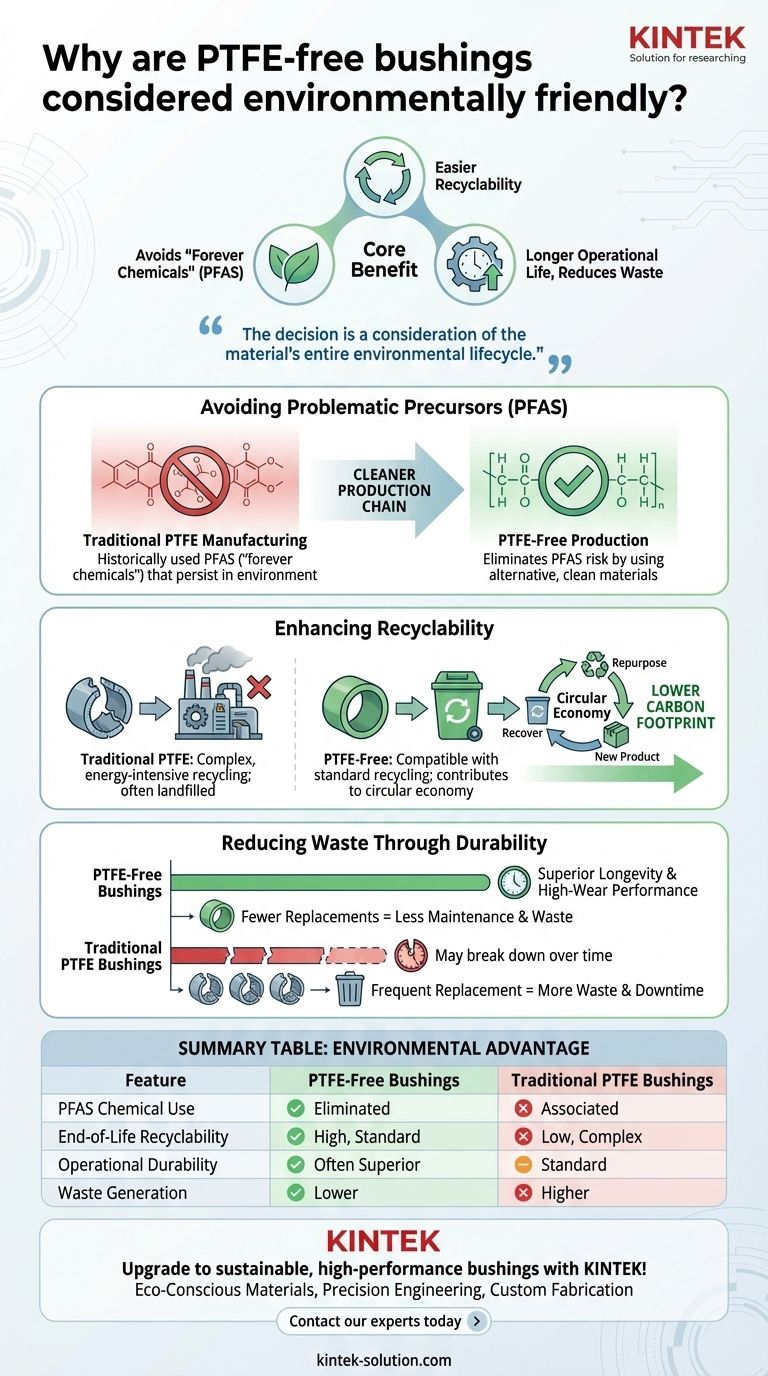

At its core, the environmental benefit of PTFE-free bushings stems from avoiding the manufacturing and disposal challenges associated with Polytetrafluoroethylene (PTFE). They eliminate the use of materials linked to persistent environmental pollutants, often referred to as "forever chemicals," and are typically designed for easier recyclability and a longer operational life, which reduces waste.

The decision between PTFE and PTFE-free bushings is not a simple matter of performance but a consideration of the material's entire environmental lifecycle. While the final PTFE product is inert, its manufacturing precursors and end-of-life persistence are significant concerns. PTFE-free alternatives aim to sidestep these issues by using more sustainable materials from the outset.

Deconstructing the "Eco-Friendly" Claim

To understand the environmental argument for PTFE-free bushings, we must look at three distinct advantages: the materials used, their end-of-life potential, and their durability in service.

Avoiding Problematic Precursors (PFAS)

The primary environmental concern with PTFE is not the final, stable polymer itself, but the chemicals historically used to manufacture it. These compounds, part of the per- and polyfluoroalkyl substances (PFAS) family, are notoriously persistent in the environment.

These "forever chemicals" can accumulate in soil, water, and living organisms, posing long-term ecological risks. By definition, PTFE-free bushings eliminate this risk by using alternative polymers and materials that do not require PFAS in their production chain.

Enhancing Recyclability

Many PTFE-free bushings are constructed from thermoplastics or metal-polymer composites that are more amenable to standard recycling processes. This simplifies end-of-life management.

A product designed for recyclability contributes to a circular economy, where materials are recovered and repurposed rather than sent to a landfill. This reduces the demand for virgin resources and lowers the overall carbon footprint of the product.

Reducing Waste Through Durability

Several modern PTFE-free bushings are engineered for superior longevity, especially in high-stress or high-wear applications. They can outperform traditional PTFE bushings, which may break down over time.

This extended service life is a direct environmental benefit. A bushing that lasts longer reduces the frequency of replacement, which in turn minimizes maintenance, downtime, and the generation of waste.

Understanding the Trade-offs: The Case for PTFE

A balanced technical assessment requires acknowledging why PTFE became a standard in the first place and addressing some of the nuances in the environmental debate.

The Reality of PTFE's "Toxicity"

In its final, solid form, PTFE is inert, non-toxic, and biocompatible. This is why it is approved by the FDA for use in non-stick cookware and medical implants. The direct health risk from a finished PTFE bushing in its operational state is minimal.

The environmental argument is almost entirely focused on its manufacturing and disposal lifecycle, not its use phase.

The Challenge of Recycling PTFE

While some sources claim PTFE is recyclable, the process is technically complex, energy-intensive, and not widely available. It requires very high temperatures to break down the strong fluorine-carbon bonds.

Therefore, in practice, most end-of-life PTFE products are disposed of in landfills, where their chemical stability means they persist indefinitely.

Unmatched Performance in Specific Contexts

PTFE still offers a unique and powerful combination of properties, including an extremely low coefficient of friction and exceptional chemical resistance. For certain highly demanding applications in the aerospace or chemical processing industries, it remains the superior technical choice.

The move to PTFE-free is about finding alternatives that are "good enough" or even better for the vast majority of common industrial applications, leaving legacy PTFE for the niche cases where no substitute will suffice.

Making the Right Choice for Your Application

The selection of a bushing should be guided by your primary goal, balancing performance requirements with sustainability commitments.

- If your primary focus is environmental marketing and regulatory simplicity: Opting for certified PTFE-free bushings eliminates any association with PFAS chemicals, simplifying your product's environmental story.

- If your primary focus is a balance of durability, cost, and sustainability for general-purpose machinery: Modern PTFE-free bushings often provide the ideal blend of long service life and a cleaner environmental profile.

- If your primary focus is peak performance in extreme chemical or temperature environments: A PTFE bushing may still be the necessary technical solution, but you must consider its end-of-life management and source from suppliers who use modern, responsible manufacturing processes.

Ultimately, the most responsible choice is an informed one, weighing both the operational demands of the application and the full lifecycle of the material.

Summary Table:

| Environmental Advantage | PTFE-Free Bushings | Traditional PTFE Bushings |

|---|---|---|

| PFAS Chemical Use | Eliminated in manufacturing | Historically associated with PFAS precursors |

| End-of-Life Recyclability | High - compatible with standard recycling | Low - complex, energy-intensive process |

| Operational Durability | Often superior, reducing replacement frequency | Standard, may wear faster in high-stress apps |

| Waste Generation | Lower due to longer life and recyclability | Higher, often ends in landfill |

Upgrade to sustainable, high-performance bushings with KINTEK!

As a leading manufacturer of precision PTFE and PTFE-free components for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical balance between material performance and environmental responsibility.

Whether you need a custom PTFE-free solution to eliminate PFAS from your supply chain or require high-volume orders of specialized bushings, KINTEK delivers:

- Eco-Conscious Materials: Avoid forever chemicals and enhance your product's sustainability story.

- Precision Engineering: Superior durability for longer service life and less waste.

- Custom Fabrication: From prototypes to high-volume production, tailored to your exact needs.

Make an informed choice for your application and the planet. Contact our experts today to discuss your bushing requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- What are the key properties of Teflon (PTFE) balls? Essential Guide for Chemical & Thermal Applications

- Why are PTFE washers considered cost-effective despite their higher initial cost? Maximize ROI with Long-Term Savings

- How do spring energized PTFE seals differ from other radial seals? Superior Performance in Extreme Conditions

- What are some examples of electrical insulation products that can be made from PTFE? High-Performance Solutions for Demanding Applications

- What is the water transmission rate of Teflon encapsulated O-rings? A Guide to Superior Moisture Sealing

- How does the chemical resistance of custom Teflon rotary shaft seals benefit industrial applications? Ensure Unmatched Reliability in Harsh Environments

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- How is glass-filled PTFE used in construction? Enhance Structural Integrity & Durability