In essence, Teflon (PTFE) balls are defined by four primary characteristics: exceptional chemical resistance, a wide operating temperature range, an extremely low coefficient of friction, and excellent electrical insulation. These properties stem from their unique fluoropolymer structure, making them a specialized material for demanding, non-mechanical applications.

The core takeaway is that PTFE balls excel in harsh chemical and thermal environments where low friction is critical, but they should be avoided for any application that requires significant mechanical strength, hardness, or wear resistance.

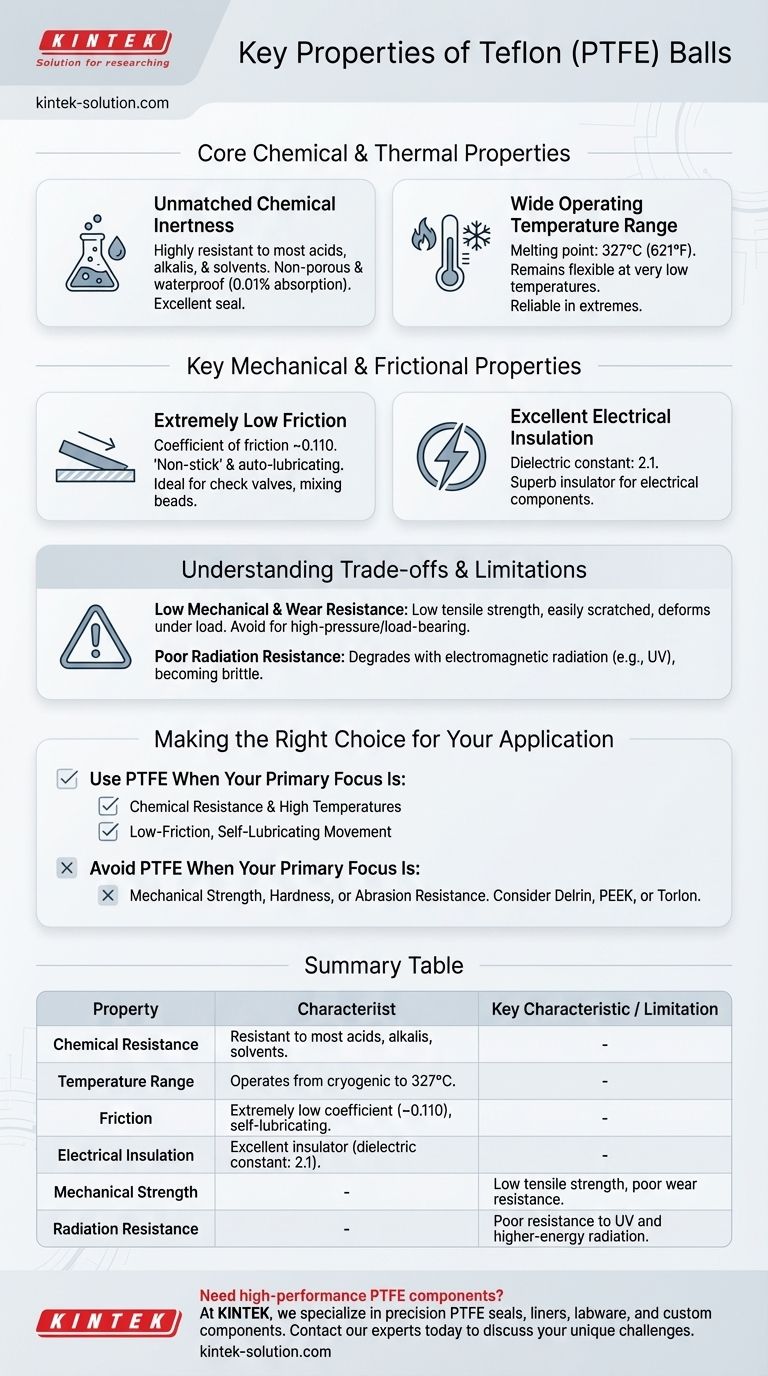

Core Chemical and Thermal Properties

The defining strengths of PTFE are its incredible stability and resilience when exposed to chemicals and extreme temperatures. This is due to the powerful carbon-fluorine bonds that form its molecular structure.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert materials known. It is highly resistant to aggressive substances, including most acids, alkalis, and solvents.

Because it is non-porous and waterproof, with a water absorption rate of just 0.01% over 24 hours, it functions as an excellent seal and barrier against caustic chemicals.

Wide Operating Temperature Range

These balls perform reliably under extreme temperature conditions. They have a very high melting point of 327°C (621°F).

Furthermore, PTFE maintains excellent flexibility and properties at very low temperatures, outperforming many other polymers in environmental extremes.

Key Mechanical and Frictional Properties

While not mechanically strong, PTFE's physical properties make it ideal for specific roles where movement and insulation are paramount.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, with a typical value around 0.110.

This gives it "non-stick" and auto-lubricating qualities, allowing components to move freely without external lubricants, which is ideal for check valves and mixing beads.

Excellent Electrical Insulation

PTFE is a superb electrical insulator with a low dielectric constant of 2.1. This makes it a valuable material for electrical components where isolation is required.

Physical Characteristics

PTFE is a relatively dense plastic with a specific gravity of around 2.2 g/cm³. It appears as a white solid at room temperature and has a Shore D hardness of about 55, which is quite soft compared to other engineering plastics.

Understanding the Trade-offs and Limitations

To use PTFE effectively, it is critical to understand its significant limitations. Misapplying this material is a common and costly mistake.

Low Mechanical and Wear Resistance

This is the most critical trade-off. PTFE has low tensile and flexural strength (2990-4970 psi and 2490 psi, respectively) and poor wear resistance.

It is easily scratched and will deform under load, making it entirely unsuitable for high-pressure or load-bearing applications like ball bearings in machinery.

Poor Radiation Resistance

The properties of PTFE can be degraded by exposure to electromagnetic radiation, including UV light and higher-energy radiation. This can cause the material to become brittle and lose its desirable qualities.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal. Use PTFE where its unique strengths are the solution, and avoid it where its weaknesses would cause failure.

- If your primary focus is chemical resistance and high temperatures: PTFE is an exceptional choice for components in chemical processing equipment, laboratory stir bars, and valves handling corrosive fluids.

- If your primary focus is low-friction, self-lubricating movement: Use PTFE for low-load applications like check valves, floats, or anywhere smooth, unlubricated motion is needed.

- If your primary focus is mechanical strength, hardness, or abrasion resistance: Do not use PTFE. Consider materials like Delrin (Acetal), PEEK, or Torlon for these demanding applications.

Ultimately, understanding both the strengths and weaknesses of PTFE is the key to successful engineering design.

Summary Table:

| Property | Key Characteristic | Key Limitation |

|---|---|---|

| Chemical Resistance | Resistant to most acids, alkalis, and solvents. | - |

| Temperature Range | Operates from cryogenic to 327°C (621°F). | - |

| Friction | Extremely low coefficient (~0.110), self-lubricating. | - |

| Electrical Insulation | Excellent insulator (dielectric constant: 2.1). | - |

| Mechanical Strength | - | Low tensile strength, poor wear resistance. |

| Radiation Resistance | - | Poor resistance to UV and higher-energy radiation. |

Need high-performance PTFE components tailored to your exact specifications?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components excel in harsh chemical and thermal environments.

Contact our experts today to discuss how our custom PTFE solutions can solve your unique application challenges.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments