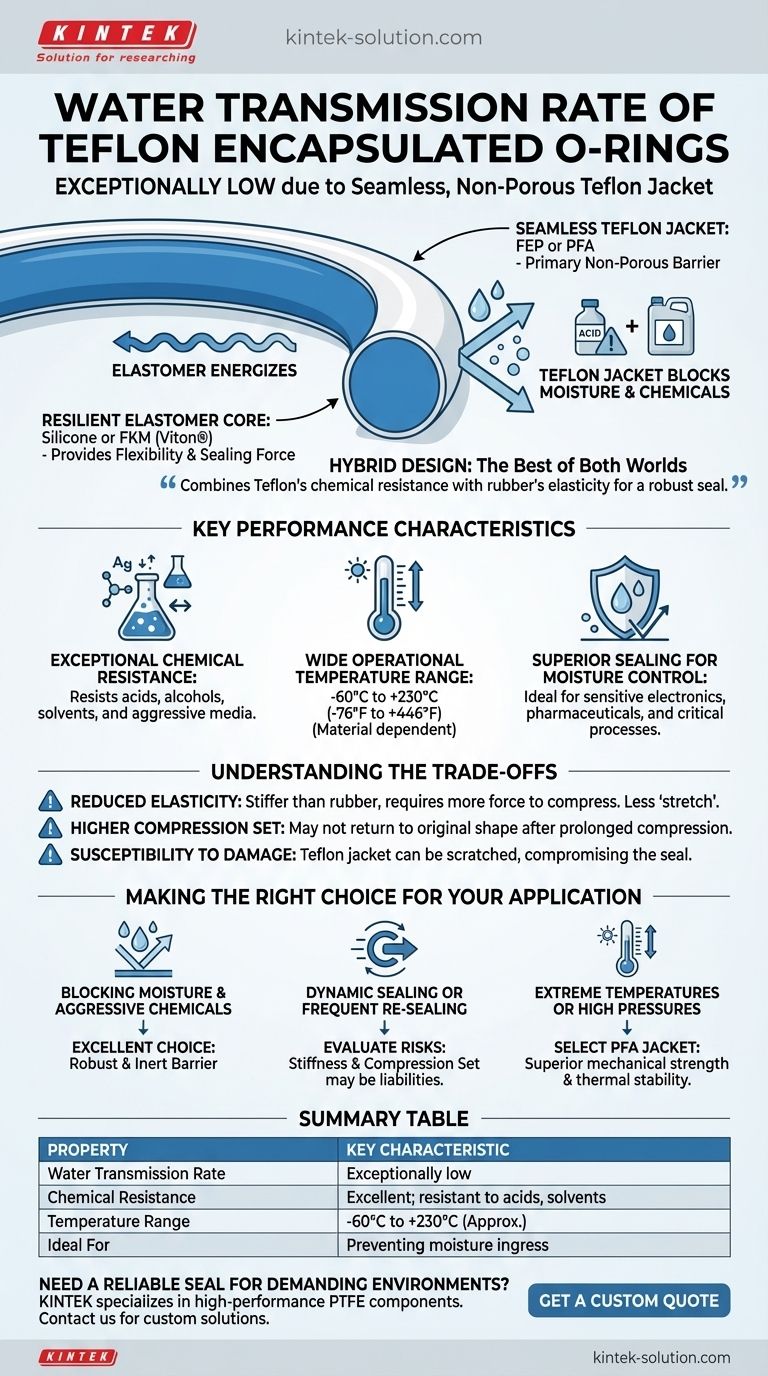

The water transmission rate of Teflon encapsulated O-rings is exceptionally low. This performance is a direct result of the seamless, non-porous Teflon (FEP or PFA) jacket that completely encloses the elastomeric core. While a precise numerical value is dependent on specific operating conditions, these seals are engineered for applications where preventing moisture ingress is a critical design requirement.

The core value of a Teflon encapsulated O-ring is its hybrid design. It combines the near-universal chemical resistance and low permeability of a solid Teflon seal with the elasticity and sealing force of a traditional rubber O-ring.

Deconstructing the Teflon Encapsulated O-Ring

To understand why these seals are so effective against water transmission, we must first look at their unique two-part construction.

The Seamless Teflon Jacket

The outer layer is a thin, seamless jacket made from Teflon resins like FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy Alkanes).

This jacket acts as the primary barrier. Its non-porous and chemically inert nature is what prevents water and other corrosive chemicals from passing through.

The Resilient Elastomer Core

Inside the jacket is a solid core made of an elastomer, typically silicone or FKM (Viton®).

This core provides the flexibility and "memory" that solid Teflon lacks. It supplies the consistent, outward pressure required to maintain a tight seal, even with fluctuations in pressure or temperature.

The Combined Benefit: A Hybrid Solution

This design synergizes the strengths of both materials. The elastomer core energizes the seal, while the Teflon jacket provides robust protection against both chemical attack and fluid permeation.

Key Performance Characteristics

The hybrid construction results in a unique set of properties that make these O-rings suitable for demanding jobs.

Exceptional Chemical Resistance

The Teflon jacket is resistant to a vast range of corrosive media. This includes aggressive substances like acids, alcohols, petroleum spirits, aromatic solvents, and naphtha.

Wide Operational Temperature Range

Teflon encapsulated O-rings can operate effectively from approximately -60°C to +230°C (-76°F to +446°F).

The precise range depends on the material choice, with the elastomer core often being the limiting factor. PFA jackets offer higher temperature resistance than FEP.

Superior Sealing for Moisture Control

The seamless Teflon encapsulation creates a leak-free barrier that is highly effective at blocking moisture. This makes them an ideal choice for protecting sensitive electronics, pharmaceuticals, or chemical processes from water contamination.

Understanding the Trade-offs

While powerful, these O-rings are not a universal solution. Their unique construction introduces specific limitations that are critical to consider.

Reduced Elasticity

The Teflon jacket is significantly stiffer than a standard rubber O-ring. This means they require more force to compress and have less "stretch," which can complicate installation in tight grooves.

Higher Compression Set

These O-rings may not return to their original shape as effectively as a pure elastomer seal after prolonged compression. This makes them less ideal for applications involving frequent assembly and disassembly.

Susceptibility to Damage

The Teflon jacket, while durable, can be scratched or nicked during installation. Any breach in the jacket compromises the O-ring's chemical and moisture resistance, as the core material becomes exposed.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to your primary operational goal.

- If your primary focus is blocking moisture and aggressive chemicals: Teflon encapsulated O-rings are an excellent choice, providing a robust and inert sealing barrier.

- If your primary focus is dynamic sealing or frequent re-sealing: Carefully evaluate the risks, as the jacket's stiffness and potential for taking a compression set may be liabilities.

- If you are operating at extreme temperatures or high pressures: Select a PFA jacket for its superior mechanical strength and thermal stability over the standard FEP.

Ultimately, choosing a Teflon encapsulated O-ring is a strategic decision for when standard elastomers fail to provide the necessary chemical or moisture protection.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Water Transmission Rate | Exceptionally low due to seamless, non-porous Teflon jacket |

| Chemical Resistance | Excellent; resistant to acids, solvents, and aggressive media |

| Temperature Range | Approx. -60°C to +230°C (-76°F to +446°F) |

| Ideal For | Applications where preventing moisture ingress is critical |

| Limitation | Stiffer than rubber O-rings; requires careful installation |

Need a Reliable Seal for Demanding Environments?

Teflon encapsulated O-rings are engineered for applications where failure is not an option. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom encapsulated O-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure your seals provide the exceptional moisture and chemical barrier your application demands, from prototypes to high-volume orders.

Contact us today to discuss your specific sealing requirements and let our experts help you find the perfect solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments