At their core, spring-energized PTFE seals differ from other radial seals by combining a durable, low-friction Polytetrafluoroethylene (PTFE) jacket with an internal metallic spring. This design provides a consistent sealing force across extreme temperatures, pressures, and chemical environments where traditional elastomeric seals would quickly degrade and fail. They are precision-engineered components designed for reliability in demanding service, not commodity parts.

The fundamental difference is not just what they are made of, but what they are designed to overcome. While a standard rubber seal relies on its own limited elasticity, a spring-energized PTFE seal uses a mechanical spring to deliver a reliable seal in conditions that would destroy conventional materials.

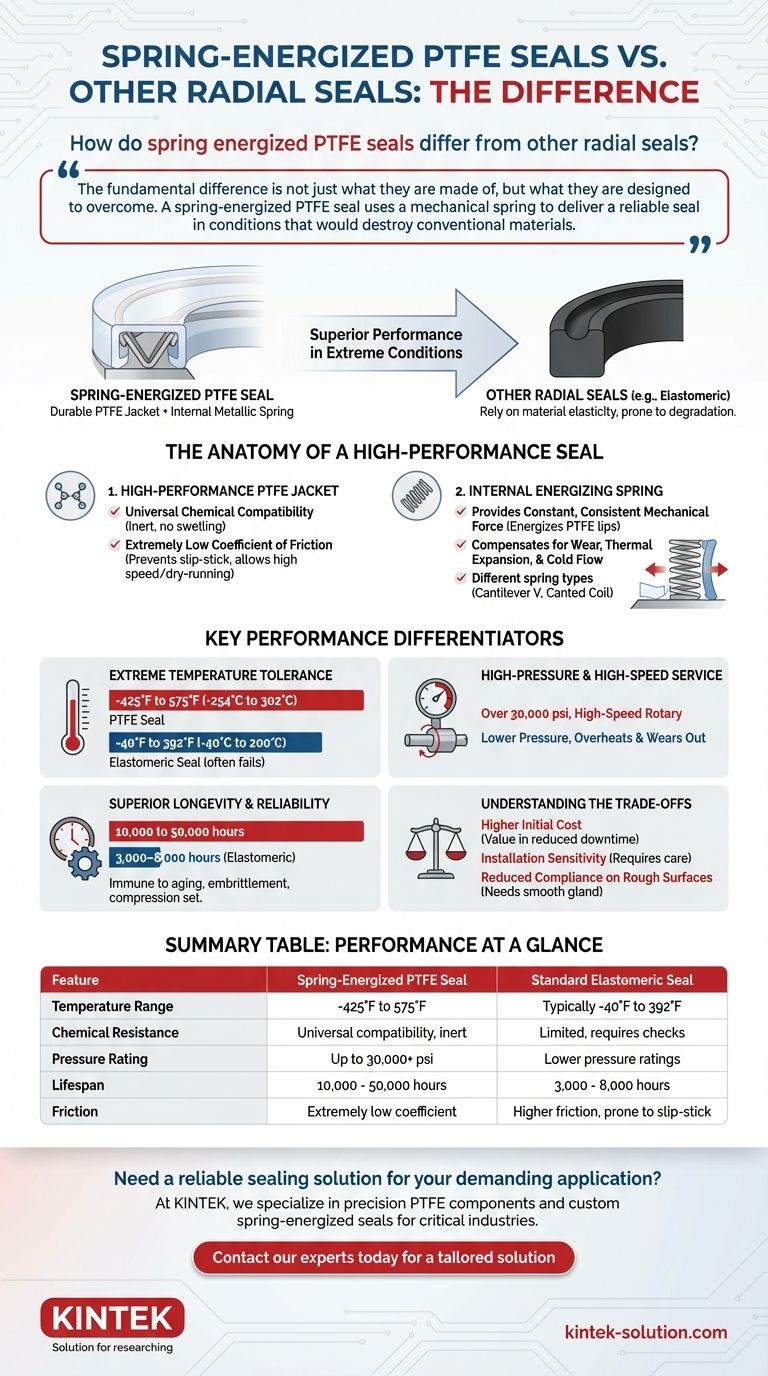

The Anatomy of a High-Performance Seal

To understand their superiority in specific applications, you must first understand their two core components. The performance of the seal is a direct result of the synergy between the outer jacket and the internal spring.

The High-Performance PTFE Jacket

The outer seal lip and body are precision-machined from PTFE and its various filled compounds. This material is chosen for a unique combination of properties that elastomers like rubber cannot match.

Key attributes include universal chemical compatibility, meaning it will not swell, degrade, or fail when exposed to aggressive solvents or chemicals. This eliminates the complex compatibility checks often required for elastomeric seals.

Furthermore, PTFE has an extremely low coefficient of friction. This prevents the "slip-stick" phenomenon common in dynamic applications and allows for high-speed service and even dry-running capabilities without generating destructive heat.

The Internal Energizing Spring

Unlike rubber, PTFE is not naturally elastic and can be prone to compression set. The internal metallic spring is the engine of the seal, providing the constant, consistent mechanical force needed to energize the PTFE jacket lips against the sealing surface.

This spring ensures a tight seal even at low pressures and compensates for any wear, thermal expansion, or material cold flow over the seal's long lifespan. Different spring types, such as cantilever V-springs or canted coil springs, can be used to precisely control the sealing load for specific applications.

Key Performance Differentiators

The combination of the PTFE jacket and energizing spring creates a seal with a performance envelope far beyond that of rubber or even standard metal seals.

Extreme Temperature Tolerance

Spring-energized PTFE seals operate effectively in a vast temperature range, from cryogenic conditions at -425°F (-254°C) up to high-temperature service at 575°F (302°C).

Most elastomeric seals have a much narrower functional window, often failing below -40°F (-40°C) or above 392°F (200°C) as the material becomes brittle or breaks down.

High-Pressure and High-Speed Service

The robust design allows these seals to handle extreme pressures, with some rated for service over 30,000 psi.

Their low-friction nature makes them ideal for high-speed rotary applications where a standard rubber seal would overheat and wear out rapidly.

Superior Longevity and Reliability

In harsh operating conditions, spring-energized PTFE seals can last 10,000 to 50,000 hours.

This dramatically outperforms rubber seals (3,000–8,000 hours) and standard metal seals (5,000–20,000 hours). The design is immune to the aging, embrittlement, and compression set that plagues elastomers over time.

Understanding the Trade-offs

While they offer superior performance, these seals are not a universal replacement for all other types. Understanding their limitations is key to proper application.

Higher Initial Cost

The use of high-performance materials and precision machining makes spring-energized PTFE seals more expensive upfront than a standard molded rubber O-ring or lip seal. Their value is realized in reduced downtime and reliability in applications where lesser seals would fail.

Installation Sensitivity

The PTFE jacket is a rigid polymer, not a soft elastomer. It is less forgiving of poor surface finishes and requires greater care during installation to avoid scratching or damaging the sealing lip, which could create a leak path.

Reduced Compliance on Rough Surfaces

In a low-demand application with a poor or irregular sealing surface, a soft, compliant rubber seal may actually perform better. The relative stiffness of the PTFE jacket requires a well-prepared and smooth gland surface to ensure a leak-tight fit.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the component's capabilities to the application's demands.

- If your primary focus is cost-effectiveness in a standard application: A traditional elastomeric seal is likely sufficient for moderate temperatures, pressures, and non-aggressive media.

- If your primary focus is reliability in extreme conditions: A spring-energized PTFE seal is the definitive choice for high/low temperatures, aggressive chemicals, high pressures, or high-speed dynamics.

- If your primary focus is purity and preventing contamination: The chemical inertness and available FDA-grade materials make PTFE seals essential for medical, food processing, and semiconductor applications.

Ultimately, choosing a spring-energized seal is an engineering decision to invest in reliability where performance is absolutely critical.

Summary Table:

| Feature | Spring-Energized PTFE Seal | Standard Elastomeric Seal |

|---|---|---|

| Temperature Range | -425°F to 575°F (-254°C to 302°C) | Typically -40°F to 392°F (-40°C to 200°C) |

| Chemical Resistance | Universal compatibility, inert | Limited, requires compatibility checks |

| Pressure Rating | Up to 30,000+ psi | Lower pressure ratings |

| Lifespan | 10,000 - 50,000 hours | 3,000 - 8,000 hours |

| Friction | Extremely low coefficient | Higher friction, prone to slip-stick |

Need a reliable sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spring-energized seals for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your seals are engineered for superior performance and longevity in extreme conditions.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining