At its core, the chemical resistance of custom Teflon rotary shaft seals provides unwavering operational integrity in environments that would cause conventional seals to fail. This inertness to acids, bases, and solvents prevents material degradation, swelling, and premature failure, ensuring equipment reliability and extending service life even at extreme temperatures.

The true benefit isn't just that Teflon resists chemicals; it's that this fundamental property, combined with its thermal stability and low friction, enables reliable sealing in applications previously considered too hostile for effective, long-term operation.

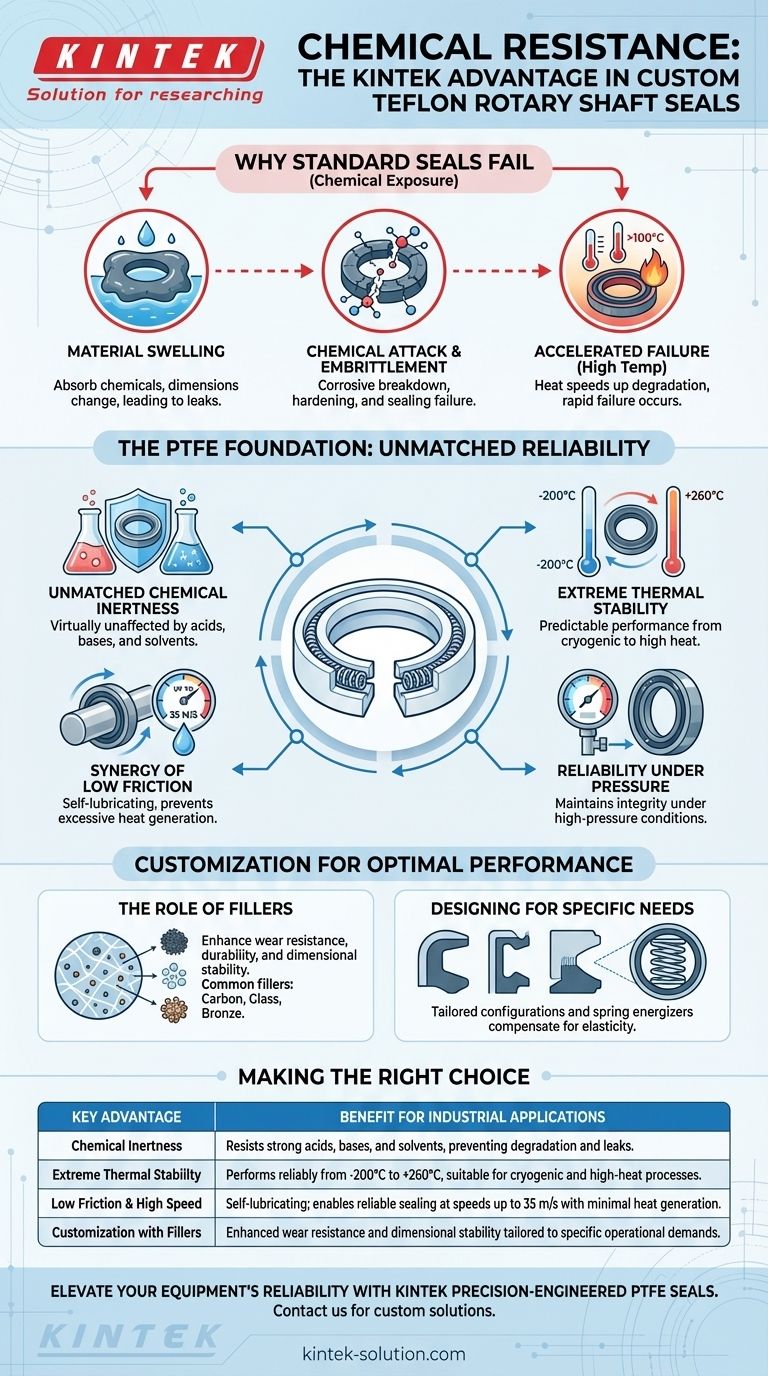

Why Chemical Exposure Degrades Standard Seals

To appreciate the advantage of Teflon (PTFE), we must first understand why many other materials fail when exposed to aggressive industrial chemicals.

Material Swelling and Softening

Many elastomeric (rubber-like) seals absorb chemicals, causing them to swell. This changes the seal's dimensions, altering the designed contact pressure against the shaft and leading to leaks.

Chemical Attack and Embrittlement

Corrosive substances can break down the molecular bonds in a seal's material. This chemical attack leads to hardening, cracking, and a complete loss of sealing capability.

Accelerated Failure at High Temperatures

Elevated temperatures significantly speed up these degradation processes. A chemical that might only slowly affect a seal at room temperature can cause rapid failure when the system heats up.

The Foundational Advantages of PTFE in Sealing

Custom Teflon seals are not just a minor upgrade; they represent a different class of material science, providing a solution where others cannot.

Unmatched Chemical Inertness

PTFE is one of the most chemically inert polymers known. It is virtually unaffected by highly corrosive substances like strong acids, bases, and aggressive solvents that are common in chemical processing and manufacturing.

Extreme Thermal Stability

This chemical resistance is maintained across an exceptionally wide temperature range, typically from -200°C to +260°C. This means the seal performs predictably whether handling cryogenic fluids or high-temperature processing agents.

The Synergy of Low Friction

Teflon has an extremely low coefficient of friction. This self-lubricating property is critical because it prevents excessive heat generation at the sealing point, especially in high-speed applications up to 35 m/s. Less heat means less thermal stress on the seal and surrounding components.

Reliability Under Pressure

The inherent strength and stability of PTFE allow these seals to maintain their integrity and sealing force under high-pressure conditions, a common requirement in hydraulic systems and chemical reactors.

Customization and Performance Trade-offs

While pure PTFE is powerful, its true potential is unlocked through customization, which also involves understanding its limitations.

The Critical Role of Fillers

Pure PTFE can be susceptible to cold flow (creep) and has moderate wear resistance. To counteract this, manufacturers add fillers like carbon, glass fiber, or bronze to create a composite material. These fillers dramatically enhance wear resistance, durability, and dimensional stability to match specific application demands.

Designing for Specific Needs

Customization extends beyond material composition. The seal's lip configuration, size, shape, and the integration of a metal spring can all be tailored. A spring energizer, for example, provides consistent force to compensate for PTFE's lower elasticity compared to rubber, ensuring a tight seal over time.

Understanding the Limitations

The primary trade-off is often a higher initial cost compared to standard elastomer seals. Additionally, their relative stiffness compared to rubber requires more precise design considerations for both the seal and the housing to ensure optimal performance.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision that directly impacts equipment uptime, safety, and maintenance costs.

- If your primary focus is reliability in corrosive environments: The chemical inertness of a custom PTFE seal is the definitive choice for preventing leaks and extending service intervals.

- If your primary focus is performance at extreme temperatures: PTFE's ability to maintain its properties from cryogenic lows to high heat makes it uniquely suitable for aerospace and specialized industrial processes.

- If your primary focus is high-speed or high-pressure sealing: A filled PTFE seal provides the low-friction and high-durability characteristics necessary to prevent premature wear and failure.

Ultimately, choosing a custom Teflon seal is an investment in operational certainty where other materials present an unacceptable risk of failure.

Summary Table:

| Key Advantage | Benefit for Industrial Applications |

|---|---|

| Chemical Inertness | Resists strong acids, bases, and solvents, preventing degradation and leaks. |

| Extreme Thermal Stability | Performs reliably from -200°C to +260°C, suitable for cryogenic and high-heat processes. |

| Low Friction & High Speed | Self-lubricating; enables reliable sealing at speeds up to 35 m/s with minimal heat generation. |

| Customization with Fillers | Enhanced wear resistance and dimensional stability tailored to specific operational demands. |

Elevate your equipment's reliability with precision-engineered PTFE seals from KINTEK.

Our custom-fabricated Teflon components, including seals, liners, and labware, are designed for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with expert material science to deliver solutions that extend service life, reduce maintenance, and prevent costly downtime in hostile environments.

Whether you need a prototype or a high-volume order, our team is ready to engineer the perfect seal for your specific requirements.

Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments