To understand the value of PTFE washers, you must look beyond the initial purchase price to their total cost of ownership over the component's lifespan. Their higher upfront cost is offset by exceptional durability, minimal maintenance requirements, and resistance to harsh conditions, which drastically reduces the need for frequent replacements and costly operational downtime.

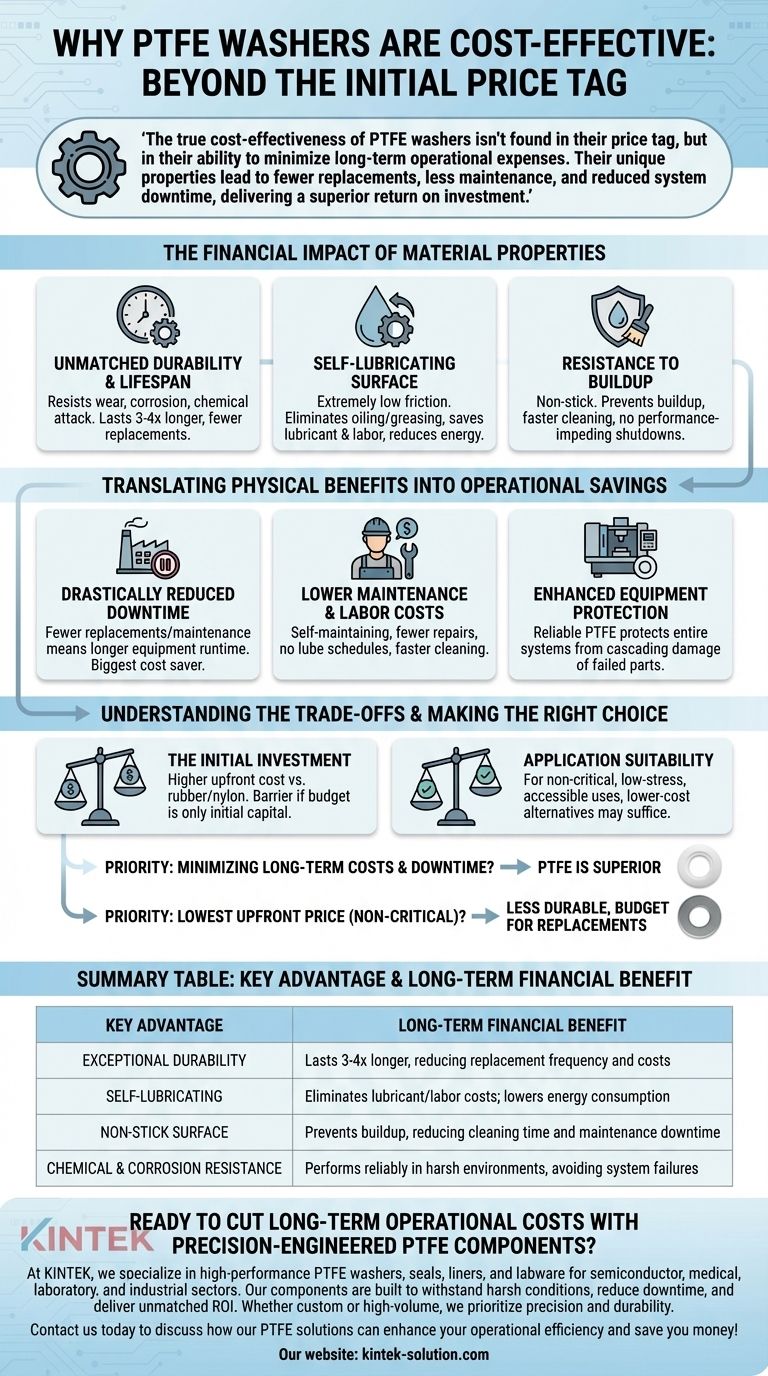

The true cost-effectiveness of PTFE washers isn't found in their price tag, but in their ability to minimize long-term operational expenses. Their unique properties lead to fewer replacements, less maintenance, and reduced system downtime, delivering a superior return on investment.

The Financial Impact of Material Properties

The long-term savings associated with PTFE washers are a direct result of the material's inherent physical characteristics. These properties solve common operational problems that traditionally lead to recurring costs.

Unmatched Durability and Lifespan

PTFE is an incredibly durable material that resists wear, corrosion, and chemical attack.

Components made from PTFE can last significantly longer—in some cases three to four times longer—than those made from conventional materials. This extended lifespan directly translates to fewer replacement cycles and reduced purchasing costs over time.

Self-Lubricating Surface

One of the most significant advantages of PTFE is its extremely low coefficient of friction, making it naturally self-lubricating.

This eliminates the need for regular oiling or greasing, saving money on both lubricants and the labor required to apply them. In dynamic systems, this low friction also reduces energy consumption.

Resistance to Buildup

PTFE is a non-stick material, similar to coatings used on cookware.

This property prevents process materials, grime, or contaminants from adhering to the washer's surface. This makes cleaning faster and simpler and prevents buildups that could otherwise impede system performance or require a shutdown for maintenance.

Translating Physical Benefits into Operational Savings

The physical advantages of PTFE create clear and measurable financial benefits that go far beyond the cost of the component itself. Understanding this connection is key to justifying the initial investment.

Drastically Reduced Downtime

The most significant hidden cost in any industrial operation is unplanned downtime.

Because PTFE washers require fewer replacements and less frequent maintenance, equipment runs longer and more reliably. This increase in operational uptime is often the single greatest source of cost savings.

Lower Maintenance and Labor Costs

The self-maintaining nature of PTFE components directly cuts down on labor expenses.

Fewer emergency repairs, no need for lubrication schedules, and faster cleaning all reduce the man-hours required to keep equipment in service.

Enhanced Equipment Protection

A failed washer can cause cascading damage to more expensive parts of an assembly.

The reliability of a PTFE washer helps protect the entire system. This prevents the collateral damage that can result from a failure of a cheaper, less durable component.

Understanding the Trade-offs

To make a fully informed decision, it's crucial to acknowledge the primary consideration when choosing PTFE. Objectivity requires looking at both sides of the equation.

The Initial Investment

The most apparent trade-off is the higher initial purchase price compared to washers made from materials like rubber or nylon.

This upfront cost can be a barrier if budgets are strictly focused on initial capital outlay rather than long-term operational expenses.

Application Suitability

For applications that are non-critical, experience low stress, and are easily accessible for frequent maintenance, the advanced properties of PTFE may be unnecessary.

In these specific scenarios, a lower-cost alternative might be a practical choice, provided you account for its shorter service life.

Making the Right Choice for Your Goal

Your decision should be guided by your specific operational and financial priorities.

- If your primary focus is minimizing operational downtime and long-term costs: PTFE washers are the superior investment due to their longevity and low-maintenance nature.

- If your primary focus is the lowest possible upfront component price for a non-critical application: A less durable material may be sufficient, but you must budget for more frequent maintenance and replacement cycles.

Ultimately, choosing PTFE is an investment in operational stability and long-term financial efficiency.

Summary Table:

| Key Advantage | Long-Term Financial Benefit |

|---|---|

| Exceptional Durability | Lasts 3-4x longer, reducing replacement frequency and costs |

| Self-Lubricating | Eliminates lubricant and labor costs; lowers energy consumption |

| Non-Stick Surface | Prevents buildup, reducing cleaning time and maintenance downtime |

| Chemical & Corrosion Resistance | Performs reliably in harsh environments, avoiding system failures |

Ready to cut your long-term operational costs with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE washers, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are built to withstand harsh conditions, reduce downtime, and deliver unmatched ROI.

Whether you need custom prototypes or high-volume orders, we prioritize precision and durability to meet your exact requirements.

Contact us today to discuss how our PTFE solutions can enhance your operational efficiency and save you money!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials