In short, PTFE expansion joints are considered an optimal solution because they offer a unique combination of material properties that directly solves the most common and destructive challenges in industrial piping. Their ability to resist aggressive chemicals, withstand extreme temperatures, and absorb constant movement makes them a uniquely versatile and reliable component for protecting system integrity.

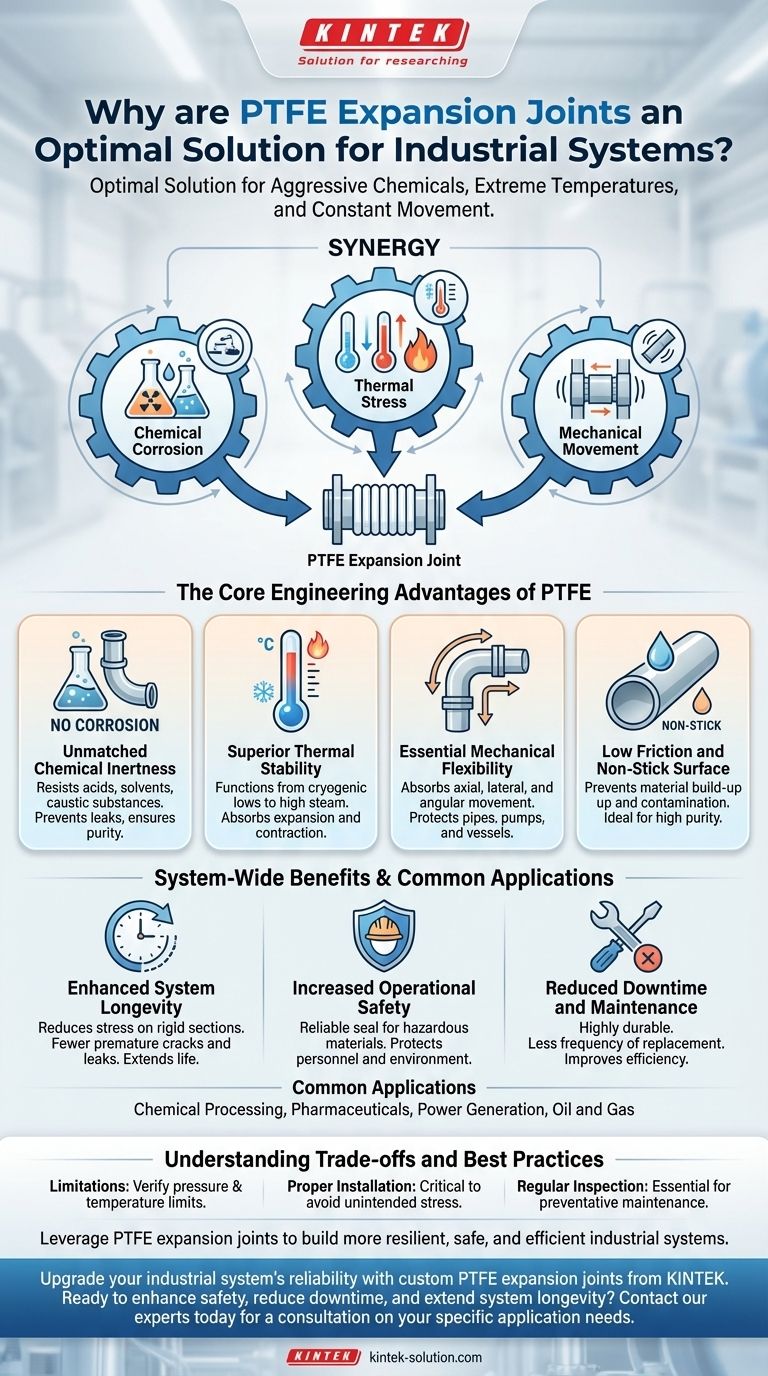

The core reason for their effectiveness is not just one feature, but the synergy of several: PTFE simultaneously addresses chemical corrosion, thermal stress, and mechanical movement, the three primary forces that lead to pipe failure, leaks, and costly downtime.

The Core Engineering Advantages of PTFE

To understand why PTFE (Polytetrafluoroethylene) is so effective, we must look at its fundamental material properties. These characteristics work together to create a robust solution for complex piping challenges.

Unmatched Chemical Inertness

PTFE is renowned for being almost completely inert to most chemicals. This means it will not corrode, degrade, or react when exposed to aggressive acids, solvents, or caustic substances commonly found in chemical processing plants.

This property is critical for preventing leaks and ensuring the purity of the media being transported, which is a non-negotiable requirement in pharmaceutical or food and beverage applications.

Superior Thermal Stability

Industrial systems rarely operate at a constant temperature. PTFE expansion joints can function effectively across a wide range of temperatures, from cryogenic lows to high-temperature steam applications.

This thermal stability allows them to absorb the expansion and contraction of pipes as temperatures fluctuate, preventing the build-up of stress that can lead to cracks or weld failures.

Essential Mechanical Flexibility

Piping systems are not static. They experience stress from thermal changes, equipment vibration, and slight misalignments.

PTFE bellows are engineered to be highly flexible, allowing them to absorb these movements in multiple directions (axial, lateral, and angular). This flexibility protects not only the piping but also connected equipment like pumps and vessels from damaging stress.

Low Friction and Non-Stick Surface

The famous non-stick quality of PTFE (often known by the brand name Teflon™) is also a significant industrial advantage.

This property prevents materials from sticking to the interior surfaces of the expansion joint, which minimizes the risk of contamination and blockages. This is especially vital in applications that demand high purity.

How These Properties Translate to System-Wide Benefits

The material science of PTFE directly results in tangible operational advantages, enhancing the safety, longevity, and efficiency of the entire system.

Enhanced System Longevity

By proactively absorbing thermal and mechanical stress, PTFE expansion joints act as the designated point of movement. This prevents stress from concentrating on rigid pipe sections or welds, which are common points of failure.

The result is a significant reduction in premature cracks and leaks, extending the operational life of the entire piping infrastructure.

Increased Operational Safety

In industries like oil and gas or chemical processing, a pipeline failure can have catastrophic consequences. By providing a reliable seal and preventing leaks of hazardous materials, PTFE expansion joints are a critical safety component.

Their ability to handle high pressures and corrosive media ensures system stability and protects both personnel and the environment.

Reduced Downtime and Maintenance

Component failure leads to unplanned downtime, which is a major source of financial loss. Because PTFE parts are highly durable and resistant to degradation, they reduce the frequency of replacement.

This reliability means less time spent on maintenance and fewer operational interruptions, directly improving industrial efficiency and output.

Common Applications Across Industries

The versatility of PTFE expansion joints makes them a preferred solution in a wide array of demanding sectors.

- Chemical Processing: Safely handling highly corrosive chemicals without degradation.

- Pharmaceuticals & Food/Beverage: Meeting stringent hygiene and safety standards by preventing contamination.

- Power Generation: Withstanding the high-pressure steam and fluctuating temperatures common in power plants.

- Oil and Gas: Managing corrosive materials and high pressures in critical upstream and downstream operations.

Understanding the Trade-offs and Best Practices

While highly effective, PTFE expansion joints are not a universal solution. An objective assessment requires understanding their limitations and operational requirements.

Limitations in Pressure and Temperature

Every material has its limits. While PTFE has an excellent temperature range, it is not suitable for the most extreme high-pressure and high-temperature applications where specialized metal expansion joints might be required. Always verify that your system's operating conditions fall within the manufacturer's specified limits.

The Critical Role of Proper Installation

The single greatest cause of premature failure is improper installation. Misalignment, over-torquing bolts, or failing to properly anchor the piping can place unintended stress on the joint, negating its benefits. Adhering strictly to manufacturer guidelines is essential.

The Necessity of Regular Inspection

In high-pressure or high-cycle environments, regular visual inspections for signs of wear, cracking, or damage are a crucial part of any preventative maintenance program. This simple practice ensures continued reliability and safety.

Making the Right Choice for Your System

Selecting the right component depends on your primary operational goal.

- If your primary focus is handling highly corrosive media: PTFE's chemical inertness makes it the default choice over most metallic alternatives for ensuring long-term compatibility.

- If your primary focus is system purity (pharma, food): The non-stick, non-contaminating surface of PTFE is essential for meeting strict hygiene and safety standards.

- If your primary focus is absorbing vibration and minor misalignment: The inherent flexibility of a PTFE expansion joint is ideal for protecting critical and sensitive equipment like pumps and compressors from mechanical stress.

- If your primary focus is extreme pressure or temperature: You must carefully verify that your conditions fall within the PTFE joint's specific limits, as a robust metal joint may be the more appropriate engineering choice.

By understanding its unique properties and operational requirements, you can leverage PTFE expansion joints to build more resilient, safe, and efficient industrial systems.

Summary Table:

| Key Advantage | Benefit for Your System |

|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents, and caustics, ensuring media purity and preventing leaks. |

| Thermal Stability | Withstands temperatures from cryogenic to high-heat, absorbing pipe expansion/contraction. |

| Mechanical Flexibility | Absorbs vibration, misalignment, and movement in multiple directions to protect equipment. |

| Low Friction Surface | Non-stick properties prevent blockages and contamination, ideal for high-purity applications. |

Upgrade your industrial system's reliability with custom PTFE expansion joints from KINTEK.

Whether you operate in semiconductor, medical, laboratory, or industrial sectors, our PTFE components—including seals, liners, and labware—are precision-engineered to handle aggressive chemicals, extreme temperatures, and constant movement. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your unique requirements.

Ready to enhance safety, reduce downtime, and extend system longevity? Contact our experts today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Do PTFE backups provide chemical resistance to rubber O-rings? The Surprising Truth About Seal Protection

- What are the benefits of using PTFE flange gaskets? Achieve Superior Sealing in Harsh Industrial Environments

- What causes a PTFE butterfly valve to leak? Diagnose and Prevent Seal Failure

- What are the characteristics of fully PFA or PTFE lined butterfly valves? Maximize Corrosion Resistance & Reliability

- In what types of medical devices are PTFE liners particularly useful? Enhance Minimally Invasive Procedures with Superior Lubricity

- Which industries commonly use PTFE expansion bellows and why? Essential for Corrosion and Contamination Control

- Are PTFE O-rings safe for use in food processing equipment? Ensure Compliance and Safety

- What materials are used for jacket profiles and springs in PTFE seals? A Guide to Material Selection