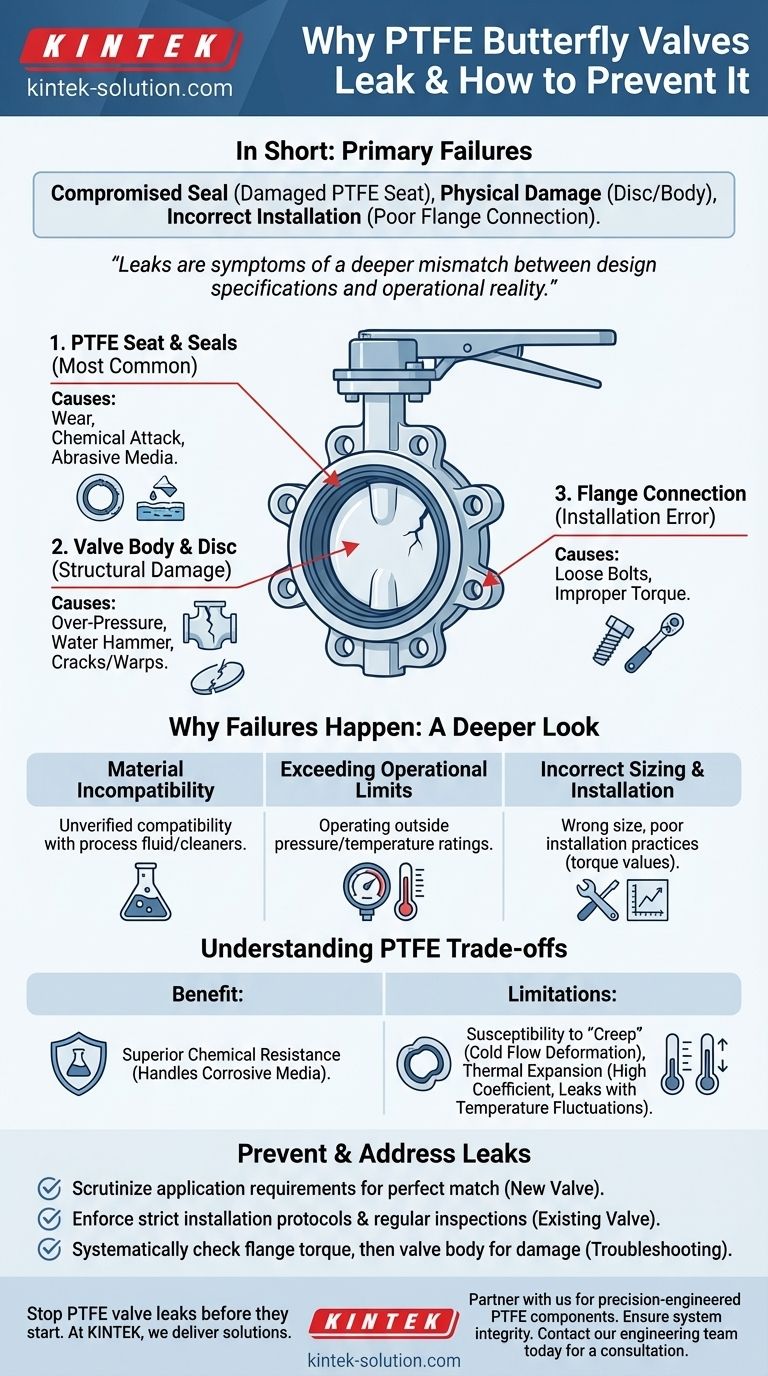

In short, a PTFE butterfly valve typically leaks due to one of three primary failures. The issue is almost always a compromised seal from a damaged PTFE seat, physical damage to the valve's core components like the disc or body, or an incorrect installation resulting in a poor flange connection.

The critical insight is that leaks are rarely spontaneous. They are symptoms of a deeper mismatch between the valve's design specifications and its operational reality, or a direct result of improper installation and maintenance practices.

Diagnosing the Root Causes of Leaks

To effectively solve a leak, you must first identify the specific point of failure. The cause almost always falls into one of three mechanical categories.

Failure Point 1: The PTFE Seat and Seals

The PTFE seat is the most common failure point. It's the soft component responsible for creating the bubble-tight seal against the metal disc.

Wear and tear from repeated cycling is a natural cause, but premature failure is often due to chemical attack or physical damage from abrasive media in the pipeline.

Failure Point 2: The Valve Body and Disc

While less common, damage to the valve's structural components can create a leak path.

A crack in the valve body or a warped or scored valve disc prevents the seat from sealing properly. This type of damage is often caused by exceeding the valve's pressure rating or by significant water hammer events.

Failure Point 3: The Flange Connection

A leak may not originate from the valve's internal sealing mechanism but from the connection to the pipe flanges.

This is almost always an installation error. Loose bolts or the improper application of torque during installation can create an uneven seal, allowing fluid to escape externally.

Why These Failures Happen: A Deeper Look

Understanding the mechanical failure is only half the battle. The more important question is why that failure occurred. The root cause usually traces back to the initial selection and installation of the valve.

Mismatch in Material Compatibility

While PTFE is known for its excellent chemical resistance, it is not invincible.

Choosing a valve without verifying full material compatibility with the process fluid, including any cleaning agents, can cause the PTFE seat to degrade, swell, or become brittle over time.

Exceeding Operational Limits

Every valve has a defined pressure and temperature rating. Operating outside these limits puts immense stress on the entire assembly.

Excessive pressure can deform the disc, damage the stem seals, or even crack the valve body, leading to catastrophic failure.

Incorrect Sizing and Installation

A valve must be the correct size for the piping system. An improperly sized valve can create flow problems and put undue stress on its components and connections.

Furthermore, poor installation practices, especially failing to follow specified bolt-tightening patterns and torque values, is a leading cause of flange leaks.

Understanding the Trade-offs of PTFE

Choosing a PTFE-lined valve is a deliberate engineering decision with specific benefits and limitations that directly impact its vulnerability to leaks.

Benefit: Superior Chemical Resistance

The primary reason to select a PTFE valve is its ability to handle a wide range of corrosive and aggressive media that would destroy other elastomers.

Limitation: Susceptibility to "Creep"

PTFE is a relatively soft material that can be subject to cold flow, or "creep." Over time, under constant pressure from the disc, the seat material can slowly deform, potentially compromising the seal. This is why proper installation and avoiding excessive torque are critical.

Limitation: Thermal Expansion

PTFE has a higher coefficient of thermal expansion than the metal body surrounding it. In systems with significant temperature fluctuations, this can cause the seal to loosen or tighten, potentially creating a leak path if not accounted for in the valve's design.

How to Prevent and Address Valve Leaks

By focusing on the root causes, you can shift from a reactive to a proactive approach for ensuring system integrity.

- If your primary focus is selecting a new valve: Scrutinize the application's chemical, pressure, and temperature requirements to ensure a perfect match with the valve's specifications.

- If your primary focus is maintaining an existing valve: Implement and enforce strict installation protocols, especially regarding bolt torque procedures, and conduct regular visual inspections for early signs of wear or external leaks.

- If you are currently troubleshooting a leak: Systematically check the flange bolts first for proper torque, then inspect the valve body for visible damage before planning a shutdown to inspect the internal seat and disc.

By treating the valve as an engineered component with specific operational limits, you can dramatically reduce the likelihood of leaks and ensure reliable performance.

Summary Table:

| Failure Point | Primary Cause | Typical Symptom |

|---|---|---|

| PTFE Seat & Seals | Chemical attack, abrasive media, wear | Internal leak past the valve disc |

| Valve Body & Disc | Over-pressure, water hammer, physical damage | Cracked body or warped/scored disc |

| Flange Connection | Incorrect bolt torque, loose bolts | External leak at the pipe connection |

Stop PTFE valve leaks before they start.

At KINTEK, we understand that a leak is more than an inconvenience—it's a sign of a mismatch between your valve and its application. For over [X] years, we've partnered with semiconductor, medical, and industrial clients to provide precision-engineered PTFE components that stand up to your most demanding processes.

We don't just sell valves; we deliver solutions. Our experts will work with you to:

- Specify the right valve based on your exact chemical, pressure, and temperature requirements.

- Provide custom fabrication for unique applications, from prototypes to high-volume orders.

- Ensure reliable performance with components manufactured to the highest standards of precision.

Ensure your system's integrity. Contact our engineering team today for a consultation on your PTFE component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments