Yes, PTFE (polytetrafluoroethylene) O-rings are widely considered safe for food processing equipment. Their fundamental properties—being non-toxic, chemically inert, and capable of withstanding high temperatures—make them suitable for direct contact with food products. However, safety is not inherent to the material alone; it must be certified to specific regulatory standards.

Choosing a sealing material is a critical decision that directly impacts food safety, regulatory compliance, and equipment reliability. While PTFE is an excellent material for these environments, you must ensure the specific O-rings you procure are explicitly certified as food-grade by a recognized body like the FDA.

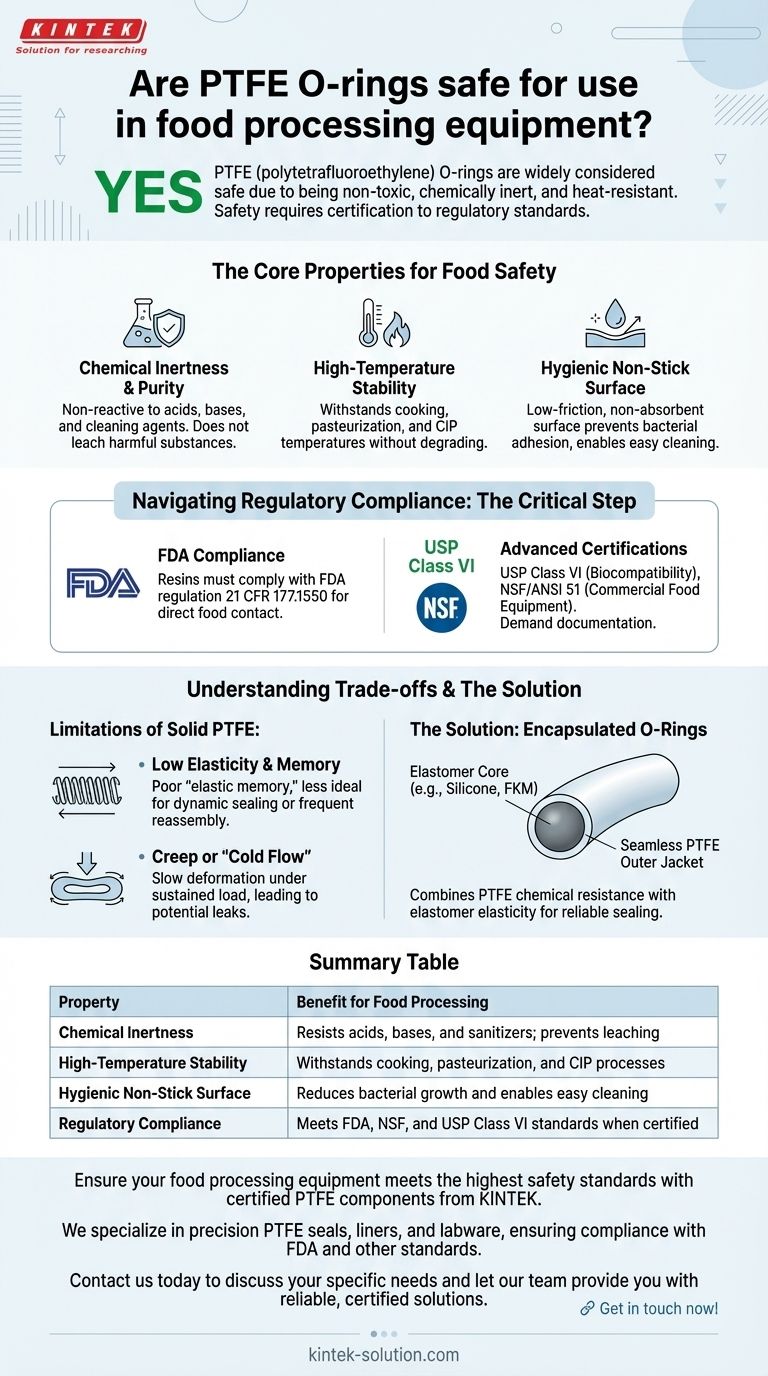

The Core Properties That Make PTFE Food-Safe

The suitability of PTFE stems from a unique combination of physical and chemical characteristics that align perfectly with the stringent demands of the food and beverage industry.

Chemical Inertness and Purity

PTFE is one of the most non-reactive materials known. It does not react with acids, bases, or the aggressive cleaning agents and sanitizers commonly used in food processing facilities.

This inertness ensures that the seal will not degrade and, more importantly, will not leach harmful substances into the food product, preserving its purity and safety.

High-Temperature Stability

Food processing often involves high temperatures for cooking, pasteurization, or sterilization. PTFE O-rings maintain their structural integrity and sealing performance across a wide temperature range, easily handling typical process and Clean-In-Place (CIP) temperatures without melting or degrading.

Hygienic and Non-Stick Surface

The famous non-stick surface of PTFE is a significant advantage for hygiene. This low-friction property prevents food particles, bacteria, and other residues from adhering to the O-ring's surface.

This makes equipment easier to clean and sanitize effectively, reducing the risk of microbial growth and cross-contamination between batches. The material is also non-absorbent, meaning it won't soak up process media.

Navigating Regulatory Compliance: The Critical Step

A material being theoretically "safe" is not enough. For use in food processing equipment, the specific component must be formally certified to prove it meets established safety standards.

Understanding FDA Compliance

The primary standard in the United States is set by the Food and Drug Administration (FDA). PTFE materials intended for food contact must be made from resins that comply with FDA regulation 21 CFR 177.1550. This confirms the material's composition is considered safe for direct food contact.

Advanced Certifications: USP Class VI and NSF

For applications with even higher purity requirements, such as pharmaceutical or certain biotech processes, other certifications are relevant.

- USP Class VI: This is a rigorous standard for biocompatibility, often required when a component might also be used in medical or pharmaceutical manufacturing.

- NSF/ANSI 51: This standard certifies that materials are safe for use in commercial food equipment.

Always insist on documentation from your supplier confirming that the specific O-rings you are purchasing meet the necessary certifications for your application.

Understanding the Trade-offs

While PTFE offers exceptional chemical and thermal resistance, it is essential to understand its mechanical limitations to ensure reliable performance.

Low Elasticity and Memory

Unlike rubber-like elastomers (e.g., Silicone, EPDM, FKM), solid PTFE O-rings have poor "elastic memory." They do not spring back to their original shape well after being compressed.

This makes them less ideal for dynamic sealing applications or for joints that are frequently disassembled and reassembled, as they may not re-seal effectively.

Creep or "Cold Flow"

Under sustained compressive load, PTFE can slowly deform over time in a process known as "creep" or "cold flow." This can eventually reduce the sealing pressure and lead to leaks, particularly in high-pressure applications.

The Solution: Encapsulated O-Rings

To overcome these mechanical limitations, encapsulated O-rings are often used. These seals feature an elastomeric core (typically Silicone or FKM) for excellent elasticity, which is then covered by a thin, seamless outer jacket of PTFE.

This design combines the superior chemical resistance of PTFE with the reliable sealing and memory of an elastomer, offering the best of both worlds for many demanding food and beverage applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's properties to your operational goals.

- If your primary focus is maximum chemical and temperature resistance: A certified, solid PTFE O-ring is an excellent choice for static applications facing aggressive chemicals or high heat.

- If your primary focus is reliable sealing in dynamic or frequently reassembled joints: An encapsulated PTFE O-ring will provide the necessary elasticity while maintaining chemical inertness.

- If your primary focus is absolute regulatory assurance: Do not rely on a generic material description. Always demand documentation from your supplier certifying compliance with FDA, NSF, or other relevant standards for your specific part.

Ultimately, verifying that your PTFE components are certified for food contact is the key to ensuring both product safety and long-term operational integrity.

Summary Table:

| Property | Benefit for Food Processing |

|---|---|

| Chemical Inertness | Resists acids, bases, and sanitizers; prevents leaching |

| High-Temperature Stability | Withstands cooking, pasteurization, and CIP processes |

| Hygienic Non-Stick Surface | Reduces bacterial growth and enables easy cleaning |

| Regulatory Compliance | Meets FDA, NSF, and USP Class VI standards when certified |

Ensure your food processing equipment meets the highest safety standards with certified PTFE components from KINTEK.

We specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you receive components that are not only compliant with FDA and other regulatory standards but also optimized for durability and performance in demanding environments.

Contact us today to discuss your specific needs and let our team provide you with reliable, certified solutions that protect your products and your reputation. Get in touch now!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the different types of PTFE rods available based on manufacturing technology? Choose the Right Type for Your Project

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability

- What are the advantages of using Teflon-coated bolts? Achieve Reliable Performance in Harsh Environments

- What design considerations are important when using PTFE seals? Optimize Your Sealing System Design

- How is Teflon used in thermal breaks in construction? Enhance Building Energy Efficiency with PTFE

- What makes PTFE expansion bellows suitable for aerospace applications? Unmatched Reliability in Extreme Environments

- What are the characteristics of PTFE coatings? Unlock Extreme Performance for Your Components

- How does CNC machining enhance PTFE part production? Achieve Unmatched Precision & Efficiency