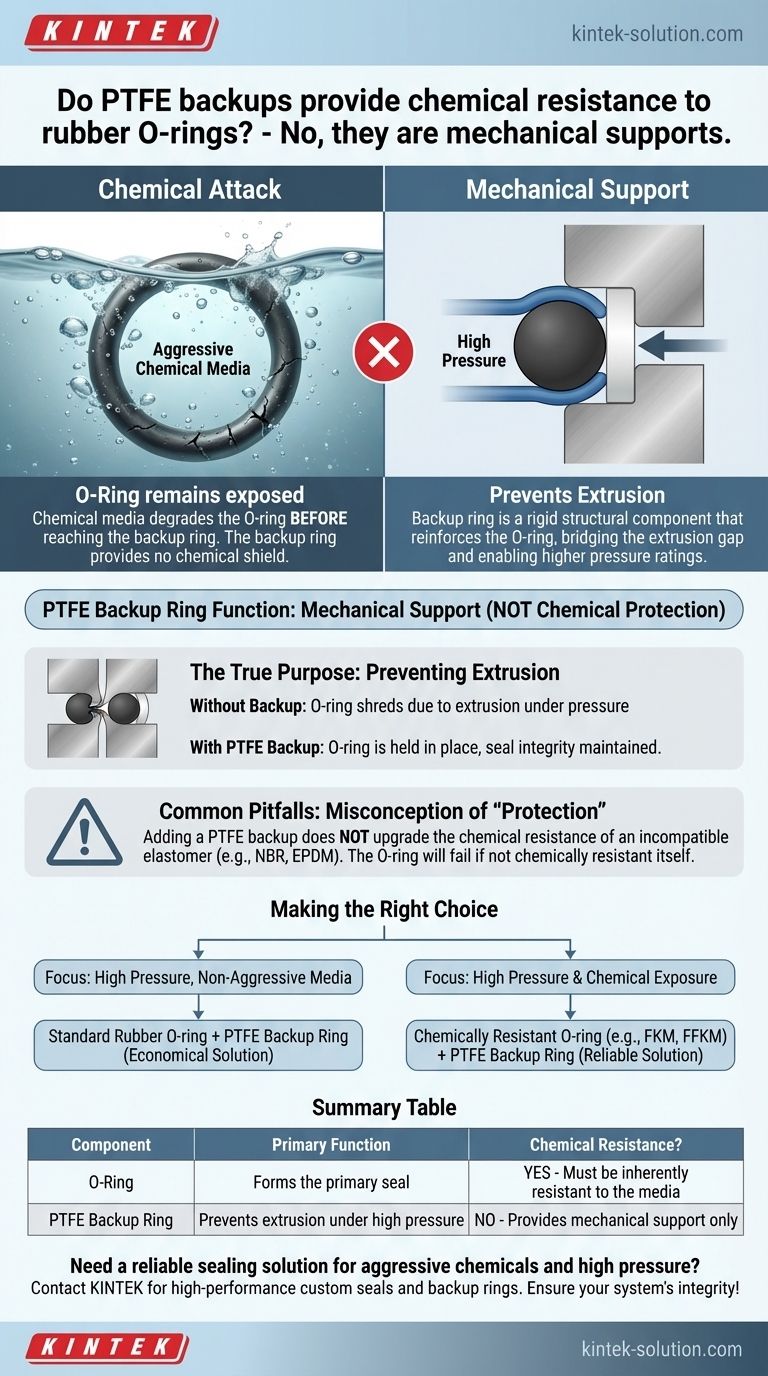

Contrary to a common assumption, a PTFE backup ring does not provide chemical resistance to a rubber O-ring. Its function is purely mechanical. Backup rings are designed exclusively to prevent the O-ring from deforming and being forced into the clearance gap under high-pressure conditions, a failure known as extrusion.

A backup ring acts as a mechanical support, not a chemical shield. The primary O-ring itself must be made of a material that is fully compatible with the system's chemical media.

The True Purpose of a Backup Ring

To understand this limitation, we must first be clear about the specific problem a backup ring is designed to solve. Its role is structural, not environmental.

Preventing Seal Extrusion

In any sealing application, there is a small gap between the moving parts. Under high pressure, this gap becomes a path of least resistance.

An elastomeric O-ring can be deformed by this pressure and squeezed into the gap. This process, extrusion, quickly shreds and destroys the seal, leading to catastrophic failure.

Reinforcing Seals Under High Pressure

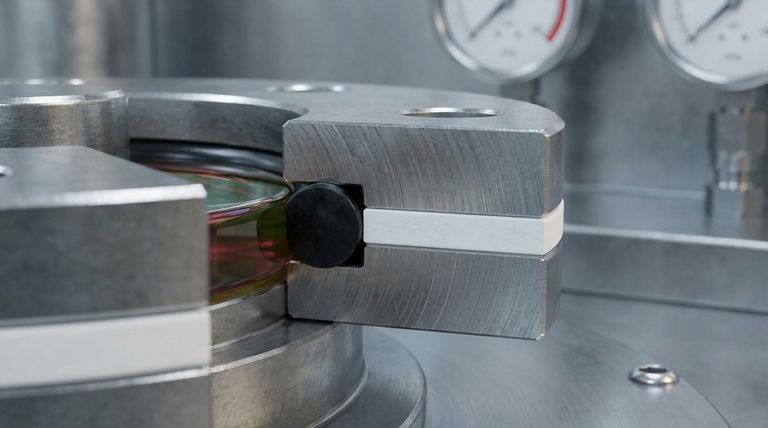

A backup ring is a rigid, strong ring, typically made of PTFE, installed on the low-pressure side of the O-ring.

When pressure is applied, the O-ring is pushed against this firm backup ring, which is strong enough to bridge the extrusion gap and hold the seal in place. This dramatically increases the pressure rating of the entire sealing system.

Why PTFE Backups Don't Provide Chemical Protection

While PTFE itself has exceptional chemical and temperature resistance, these properties do not transfer to the O-ring it supports in a typical backup configuration.

The O-Ring Remains Exposed

A backup ring is positioned behind the O-ring, away from the direct pressure source. The primary O-ring still forms the initial seal and is fully wetted by the system fluid.

The chemical media will attack and degrade an incompatible rubber O-ring long before it ever reaches the backup ring. The backup ring provides no barrier or shield.

Material Properties vs. Application Function

Using PTFE for backup rings is a choice based on its mechanical properties: it has a low coefficient of friction and high compressive strength.

These traits make it an ideal support material. However, this is fundamentally different from using a solid PTFE O-ring, which would provide both the primary seal and chemical resistance.

Common Pitfalls to Avoid

Confusing the role of the O-ring with that of its support component is a frequent and costly error in system design.

The Misconception of "Protection"

It is incorrect to assume that adding a PTFE backup ring "upgrades" the chemical resistance of a standard NBR or EPDM O-ring.

This approach will inevitably lead to seal failure if the base elastomer is not compatible with the process fluid. The O-ring will swell, harden, or dissolve, compromising the seal regardless of the backup ring behind it.

Selecting the Wrong Primary Seal

The most critical decision is the material of the O-ring itself. It must be chosen based on its ability to withstand the application's full range of chemicals and temperatures.

Materials like FKM, FFKM, or solid PTFE are specified for aggressive chemical environments. A backup ring is only added if the system pressure also exceeds the extrusion resistance of that chosen O-ring.

Making the Right Choice for Your Goal

To ensure system integrity, you must select your components based on the distinct challenges of your application.

- If your primary focus is high pressure with non-aggressive media: A standard rubber O-ring (like NBR) paired with a PTFE backup ring is an effective and economical solution.

- If your primary focus is both high pressure and chemical exposure: You must select an O-ring material (like FKM or FFKM) that is inherently resistant to the media, and then add a backup ring if needed for pressure.

Choosing the O-ring material to match the chemical environment is the only way to guarantee a reliable, long-lasting seal.

Summary Table:

| Component | Primary Function | Chemical Resistance? |

|---|---|---|

| O-Ring | Forms the primary seal | YES - Must be inherently resistant to the media |

| PTFE Backup Ring | Prevents extrusion under high pressure | NO - Provides mechanical support only |

Need a reliable sealing solution for aggressive chemicals and high pressure?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and backup rings, for the semiconductor, medical, laboratory, and industrial sectors. Don't risk seal failure—our experts can help you select or fabricate the perfect O-ring and backup ring combination to meet your specific chemical and pressure requirements, from prototypes to high-volume orders.

Contact us today for a consultation and ensure your system's integrity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency