At their core, fully PFA or PTFE lined butterfly valves are engineered for one primary purpose: providing reliable flow control in highly corrosive environments. Their defining characteristics are exceptional chemical inertness derived from the fluoropolymer lining, a wide operational temperature range, and the ability to provide a tight seal in large-diameter piping where solid alloy valves would be prohibitively expensive.

The decision to use a PFA/PTFE lined butterfly valve is a strategic one. It prioritizes maximum chemical resistance and operational reliability, offering the performance of exotic materials without their associated cost, particularly in larger pipe sizes.

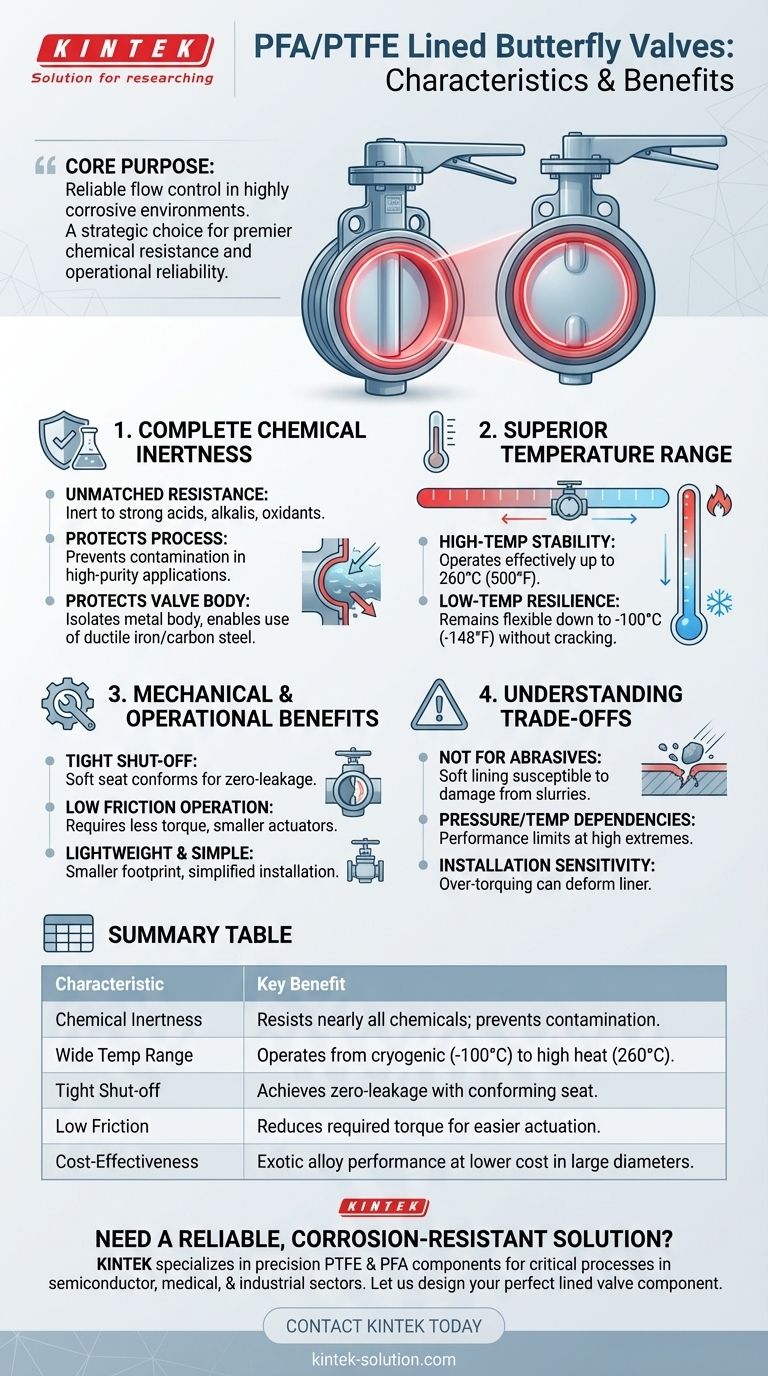

The Core Advantage: Complete Chemical Inertness

The primary reason to specify a PFA or PTFE lined valve is its near-universal resistance to chemical attack. The lining isolates the valve's structural components from the process media.

Unmatched Resistance to Aggressive Media

PTFE (Polytetrafluoroethylene) and PFA (Perfluoroalkoxy) are fluoropolymers with extremely strong carbon-fluorine bonds. This molecular structure makes them inert to nearly all chemicals, including strong acids, alkalis, and potent oxidants.

Protecting the Process Media

In high-purity applications, such as pharmaceuticals or specialty chemicals, the process fluid must remain uncontaminated. The inert lining ensures that the media never touches the valve's metal body, preventing leaching or corrosion byproducts from entering the stream.

Protecting the Valve Body

The lining allows for the use of less expensive body materials, like ductile iron or carbon steel. The lining acts as a permanent, non-corrodible barrier, protecting the structural integrity of the valve body from the aggressive media it is controlling.

Superior Performance Across a Wide Temperature Range

Beyond chemical resistance, these valves are valued for their ability to perform reliably in both very hot and very cold conditions.

High-Temperature Stability

Lined valves can operate effectively at high temperatures, with typical upper limits ranging from 200°C to 260°C (392°F to 500°F). This makes them suitable for many heated chemical processing applications.

Low-Temperature Resilience

Unlike many materials that become brittle at low temperatures, PTFE remains flexible and soft even at cryogenic temperatures as low as -100°C (-148°F) or below. This resilience ensures the valve can maintain a tight seal without cracking or failing.

Mechanical and Operational Characteristics

The design of a lined butterfly valve provides distinct functional benefits related to sealing, operation, and installation.

Achieving a Tight Shut-off

The soft, resilient nature of the PFA/PTFE seat allows it to conform perfectly to the valve disc. This creates an exceptionally tight seal, often achieving zero-leakage performance for critical isolation tasks.

Low Friction, Easy Operation

PTFE has one of the lowest coefficients of friction of any solid material. This property means less torque is required to open and close the valve, allowing for the use of smaller, less expensive, and more energy-efficient actuators.

Lightweight and Simple Installation

Butterfly valves are inherently lighter and have a smaller footprint than comparable gate or globe valves. This simplifies installation, reduces the need for extensive pipe support, and lowers overall project costs.

Understanding the Trade-offs

While highly effective, lined butterfly valves are not a universal solution. Understanding their limitations is key to successful application.

Not Suited for Abrasive Media

The soft fluoropolymer linings that provide such an excellent seal are susceptible to damage from abrasive particles or slurries. Abrasives can score or erode the liner, leading to leaks and eventual failure.

Pressure and Temperature Dependencies

The performance of the valve is subject to a pressure/temperature curve. At the highest end of the temperature range, the maximum allowable operating pressure will decrease. High pressure combined with high temperature can cause the liner to deform or "creep," compromising the seal.

Installation Sensitivity

Proper installation is critical. Over-torquing the flange bolts can deform the liner, which can prevent the disc from seating properly or even from moving at all. This can damage the liner and cause premature valve failure.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its characteristics to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: A PFA/PTFE lined butterfly valve is an excellent choice, offering near-universal chemical resistance at a lower cost than exotic alloys.

- If your primary focus is high-purity applications: The inert lining prevents metal leaching and product contamination, ensuring the integrity of your process media.

- If your primary focus is cost-effective control in large-diameter piping: These valves provide a significant cost advantage over solid alloy valves while maintaining robust performance.

- If your application involves abrasive slurries or extreme pressure/temperature combinations: You must carefully evaluate the valve's specific limits or consider a more robust alternative, such as a metal-seated valve.

Choosing a lined valve is a deliberate engineering decision that balances premier chemical defense with practical, economic reality.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Chemical Inertness | Resists nearly all acids, alkalis, and oxidants; prevents contamination. |

| Wide Temperature Range | Operates from cryogenic (-100°C) to high heat (260°C). |

| Tight Shut-off | Achieves zero-leakage performance with a soft, conforming seat. |

| Low Friction Operation | Reduces required torque for easier actuation. |

| Cost-Effectiveness | Provides exotic alloy performance at a lower cost, especially in large diameters. |

Need a reliable, corrosion-resistant valve solution?

KINTEK specializes in the precision manufacturing of high-performance PTFE and PFA components, including custom-fabricated liners and seals. Our expertise ensures your critical processes in the semiconductor, medical, laboratory, and industrial sectors are protected from aggressive media.

We can help you select or design the perfect lined valve component for your specific chemical, temperature, and purity requirements, from prototype to high-volume production.

Contact KINTEK today to discuss your application and discover how our custom PTFE solutions can enhance your system's reliability and cost-efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications