In the landscape of industrial sealing, PTFE flange gaskets stand out for their powerful combination of extreme chemical inertness, a wide operational temperature range, and exceptional durability. This unique profile makes them a highly reliable choice for creating tight, leak-proof seals in demanding applications, ultimately reducing maintenance costs and minimizing operational downtime.

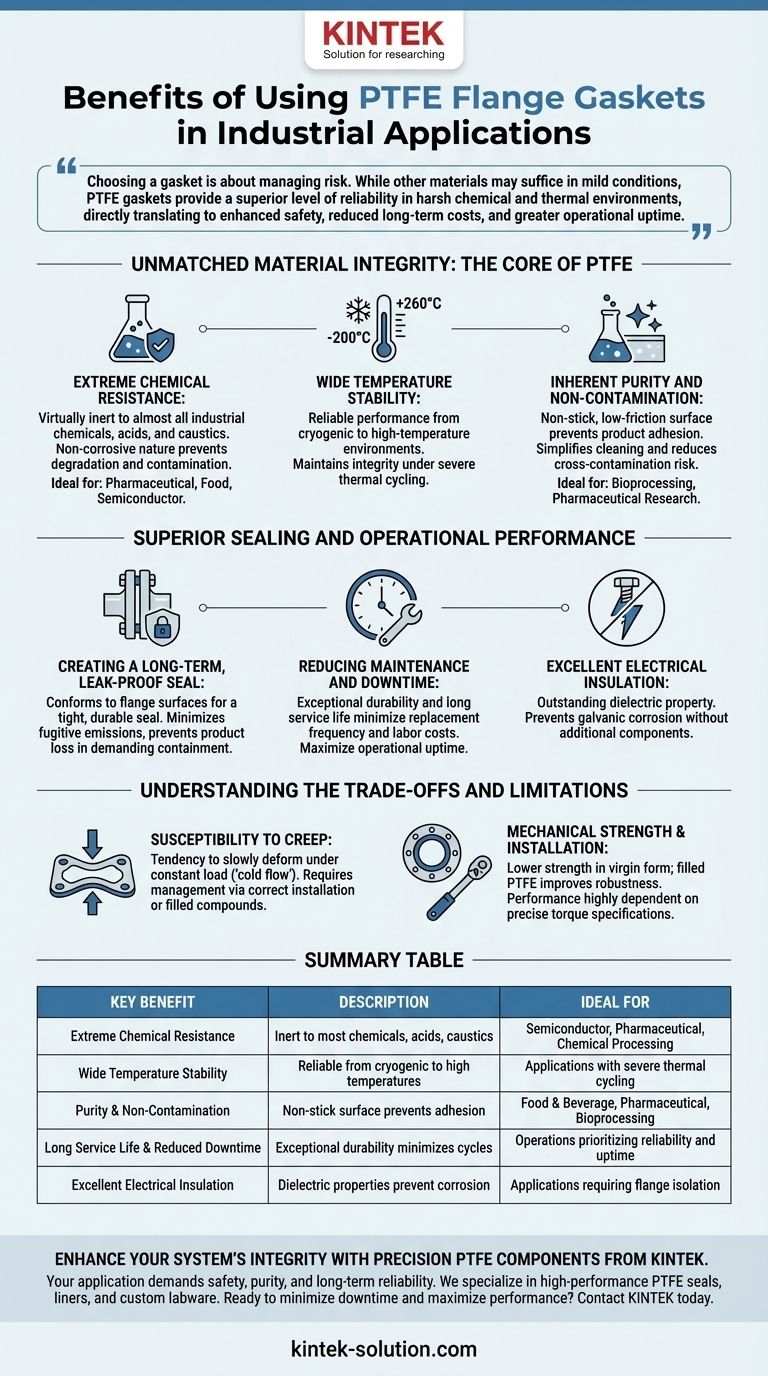

Choosing a gasket is about managing risk. While other materials may suffice in mild conditions, PTFE gaskets provide a superior level of reliability in harsh chemical and thermal environments, directly translating to enhanced safety, reduced long-term costs, and greater operational uptime.

Unmatched Material Integrity: The Core of PTFE

The primary benefits of PTFE (Polytetrafluoroethylene) stem from its fundamental molecular structure, which gives it properties that few other polymers can match.

Extreme Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and caustics. This makes it the default choice for systems handling aggressive or corrosive media.

Its non-corrosive nature ensures that the gasket itself will not degrade or contaminate the process fluid, which is critical in pharmaceutical, food, and semiconductor applications.

Wide Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature range. They maintain their integrity and sealing capability in both cryogenic conditions and high-temperature environments.

This versatility extends the service life of the gasket and the system it protects, ensuring consistent performance even under severe thermal cycling.

Inherent Purity and Non-Contamination

The material has a non-stick, low-friction surface. This prevents process media from adhering to the gasket, simplifying cleaning and reducing the risk of cross-contamination between batches.

This property is invaluable in industries like bioprocessing and pharmaceutical research, where maintaining the purity of APIs (Active Pharmaceutical Ingredients) or other sensitive materials is paramount.

Superior Sealing and Operational Performance

Beyond its material properties, PTFE's mechanical behavior delivers significant operational advantages that contribute directly to system efficiency and safety.

Creating a Long-Term, Leak-Proof Seal

PTFE's ability to conform to flange surfaces creates a tight and durable seal. This minimizes fugitive emissions and prevents loss of valuable or hazardous product.

Its reliability makes it suitable for the most demanding containment systems, including those for toxic gases or underground storage, where leakage is not an option.

Reducing Maintenance and Downtime

Due to their exceptional durability and resistance to degradation, PTFE gaskets have a very long service life, even under continuous use in harsh conditions.

This longevity directly reduces the frequency of gasket replacement, minimizing associated labor costs and, more importantly, costly operational downtime.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator, or dielectric. In applications where flange isolation is needed to prevent galvanic corrosion or interrupt electrical currents, PTFE serves this dual purpose without requiring additional components.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Susceptibility to Creep

PTFE is a relatively soft material and can be susceptible to creep, or "cold flow." This is the tendency of the material to slowly deform over time when held under a constant load (i.e., the pressure from the flange bolts).

This can lead to a loss of bolt torque and potential leakage if not managed properly through correct installation or the use of filled PTFE compounds.

Mechanical Strength Considerations

In its pure, "virgin" form, PTFE has lower mechanical strength compared to metallic or semi-metallic gaskets. It may not be the ideal choice for extremely high-pressure systems without reinforcement.

To counter this, filled PTFE gaskets incorporate materials like glass, carbon, or graphite to improve creep resistance and mechanical robustness for more demanding service.

Installation Sensitivity

The performance of a PTFE gasket is highly dependent on proper installation. Over-tightening can crush the material and accelerate creep, while under-tightening will fail to create an effective seal. Following precise torque specifications is critical.

Making the Right Choice for Your Application

Selecting the right gasket depends entirely on your operational priorities. PTFE is often the superior choice when long-term reliability in challenging environments is the goal.

- If your primary focus is maximum chemical resistance: PTFE's near-universal inertness makes it the safest and most reliable choice for sealing aggressive acids, bases, and solvents.

- If your primary focus is purity and non-contamination: PTFE is ideal for food, beverage, and pharmaceutical applications where preventing product adhesion and contamination is critical.

- If your primary focus is reducing long-term maintenance: The exceptional durability of PTFE gaskets minimizes replacement cycles, directly lowering downtime and labor costs over the system's life.

- If your primary focus is very high-pressure service: Consider a filled PTFE or a composite gasket, as pure PTFE may be too susceptible to creep in these applications.

Ultimately, investing in PTFE gaskets is a strategic decision to enhance system integrity and operational resilience.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Extreme Chemical Resistance | Virtually inert to almost all industrial chemicals, acids, and caustics. | Semiconductor, Pharmaceutical, Chemical Processing |

| Wide Temperature Stability | Reliable performance from cryogenic to high-temperature environments. | Applications with severe thermal cycling |

| Purity & Non-Contamination | Non-stick surface prevents product adhesion and cross-contamination. | Food & Beverage, Pharmaceutical, Bioprocessing |

| Long Service Life & Reduced Downtime | Exceptional durability minimizes replacement cycles and maintenance costs. | Operations prioritizing long-term reliability and uptime |

| Excellent Electrical Insulation | Serves as a dielectric, preventing galvanic corrosion. | Applications requiring flange isolation |

Enhance Your System's Integrity with Precision PTFE Components from KINTEK

Your application demands a seal that guarantees safety, purity, and long-term reliability. The unique properties of PTFE make it the ideal choice for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors.

At KINTEK, we don't just supply parts; we provide solutions. We specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. Whether you need a standard item or a custom-fabricated solution—from prototypes to high-volume orders—we prioritize precision production to meet your exact specifications.

Ready to minimize downtime and maximize performance?

Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems