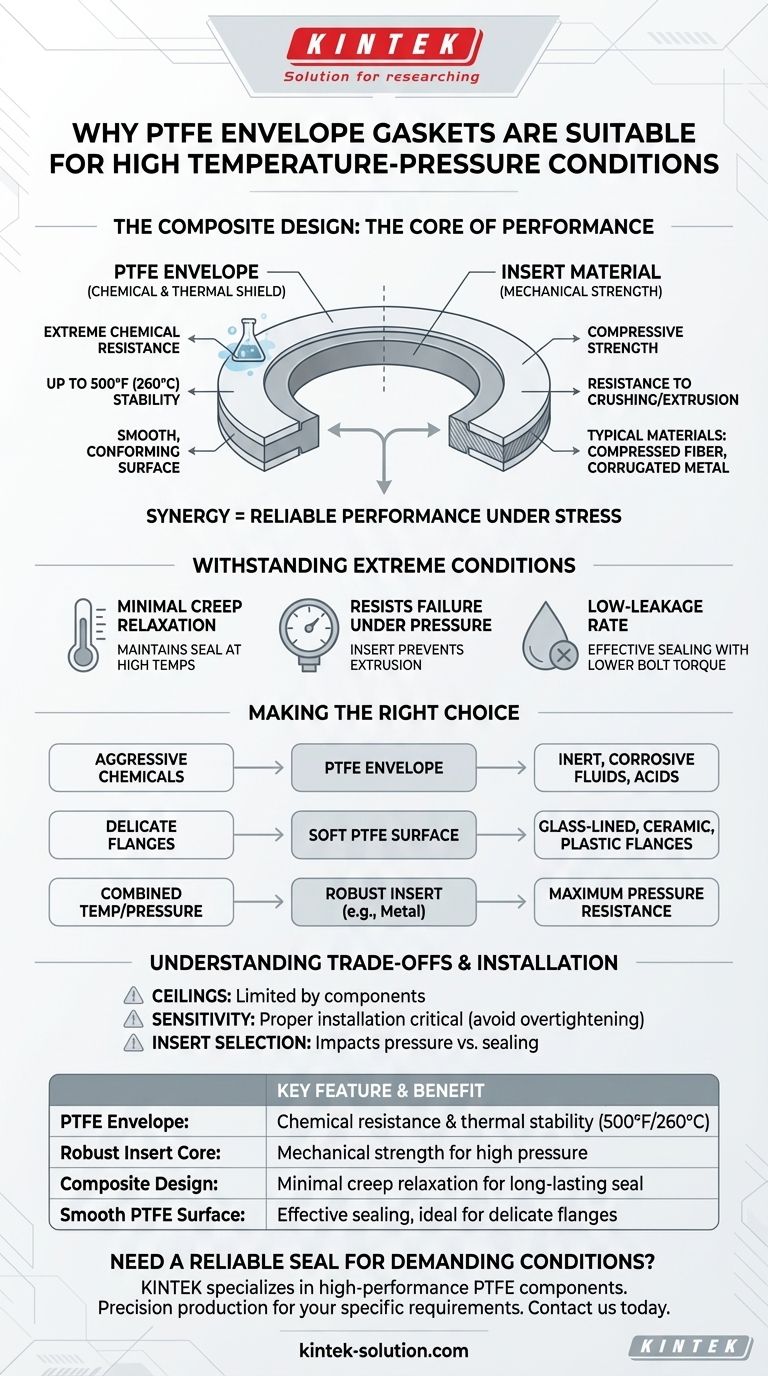

At its core, the suitability of a PTFE envelope gasket for high temperature and pressure conditions stems from its clever composite design. This design combines the exceptional chemical and thermal resistance of a Polytetrafluoroethylene (PTFE) outer shell with the mechanical strength and resilience of a separate inner core material, creating a seal that leverages the best properties of both.

A PTFE envelope gasket is not a single material, but a system. The PTFE "envelope" acts as a chemically inert and heat-resistant shield, while the inner "insert" provides the robust mechanical structure needed to withstand high pressures without failing.

The Anatomy of a High-Performance Seal

To understand why this gasket excels, you must first understand its two-part construction. It is this combination that overcomes the inherent limitations of using a solid PTFE gasket in high-pressure scenarios.

The PTFE Envelope: A Chemical and Thermal Shield

The outer jacket is made entirely of PTFE, a fluoropolymer renowned for its unique properties. This envelope is the only part of the gasket that comes into contact with the process fluid.

Its primary role is to provide extreme chemical resistance. PTFE is virtually inert, able to handle a wide range of acids, alkalis, and corrosive substances that would destroy other sealing materials.

It also delivers superior thermal stability. PTFE maintains its integrity and does not melt or degrade at continuous service temperatures up to 500°F (260°C), making it ideal for steam systems and other hot applications.

The Insert Material: The Source of Mechanical Strength

Inside the PTFE jacket sits a core insert. This insert is what gives the gasket its structural integrity and ability to handle pressure.

This core is typically made from a more mechanically robust material, such as compressed non-asbestos fiber or corrugated metal. This insert provides the resistance to crushing and extrusion that PTFE alone lacks. It gives the gasket the "body" needed to withstand high bolt loads and internal system pressures.

How This Design Withstands Extreme Conditions

The synergy between the envelope and the insert directly translates into reliable performance under the simultaneous stresses of heat and pressure.

Maintaining Seal Integrity at High Temperatures

A critical failure point for many materials under heat and load is "creep relaxation"—the tendency to deform over time, causing the seal to loosen.

PTFE exhibits minimal creep relaxation compared to other polymers. This means it maintains its shape and continues to exert sealing pressure on the flange faces even after prolonged exposure to high temperatures, ensuring a long-lasting, reliable seal.

Resisting Failure Under High Pressure

While PTFE is thermally stable, it is a relatively soft material. A solid PTFE gasket could be squeezed out or "extruded" from between flanges under high pressure.

The internal insert in an envelope gasket provides the necessary compressive strength. The insert bears the brunt of the mechanical load, preventing the softer PTFE envelope from being forced out of the joint and ensuring the seal remains intact.

Ensuring a Low-Leakage Rate

The smooth, conforming surface of the PTFE envelope creates an exceptionally tight seal against the flange faces.

This allows it to achieve effective sealing with lower surface compression (i.e., less bolt torque) than many other gasket types. It reliably seals mating surfaces against pressurized fluids and gases without leakage, even in complex or imperfect flange conditions.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Ceilings

The performance of the gasket is ultimately limited by its components. While PTFE has a high service temperature, the insert material may have a lower limit. The maximum pressure is also dictated by the strength of the insert and the design of the flange.

Sensitivity to Installation

The effectiveness of this gasket system is highly dependent on proper installation. Overtightening the bolts can damage the relatively thin PTFE envelope, compromising its chemical resistance and creating a potential leak path. Flange surfaces must be clean and in good condition.

Insert Material Selection is Critical

The choice of insert material directly impacts the gasket's performance. A softer insert may provide better sealing on irregular flanges but will have lower pressure ratings. A metallic insert provides maximum pressure resistance but requires higher bolt loads and better flange conditions.

Making the Right Choice for Your Application

Use the unique strengths of this gasket design to solve specific sealing challenges.

- If your primary focus is aggressive chemical service: The inert PTFE envelope makes this one of the best choices for safely sealing corrosive fluids, acids, and solvents.

- If your primary focus is protecting delicate flanges: The soft, conforming nature of the PTFE surface is ideal for use with glass-lined, ceramic, or plastic flanges where a hard gasket could cause damage.

- If your primary focus is combined temperature and pressure: Ensure you select a gasket with an insert material (like corrugated metal) specifically rated for your application's mechanical and thermal demands.

The brilliance of the PTFE envelope gasket lies in its ability to combine material properties to create a sealing solution that is more capable than the sum of its parts.

Summary Table:

| Key Feature | Benefit |

|---|---|

| PTFE Envelope | Provides extreme chemical resistance and thermal stability (up to 500°F/260°C). |

| Robust Insert Core | Delivers mechanical strength to withstand high pressure and prevent extrusion. |

| Composite Design | Offers minimal creep relaxation for long-lasting seal integrity under stress. |

| Smooth PTFE Surface | Ensures effective sealing with lower bolt torque, ideal for delicate flanges. |

Need a reliable seal for demanding conditions?

KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your gaskets are engineered to handle your specific temperature, pressure, and chemical requirements—from prototypes to high-volume orders.

Contact us today to discuss your application and get a solution that delivers unmatched reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability

- What factors have contributed to the expansion of the global supply chain for Teflon machined parts? Key Drivers and Industry Insights

- What are the advantages of using PTFE Expansion Bellows? Maximize System Integrity & Uptime

- What factors should be considered when selecting an expanded PTFE gasket? Optimize Your Seal for Performance

- What is the water transmission rate of Teflon encapsulated O-rings? A Guide to Superior Moisture Sealing

- Why are PTFE ball valves preferred for cryogenic applications? Unlock Reliable Sealing at Ultra-Low Temperatures

- What are the differences in installation and maintenance between spiral and split PTFE backup rings? A Guide to Maximizing Performance and Minimizing Downtime