At its core, the primary advantage of a PTFE expansion bellow is its unique ability to solve multiple industrial challenges simultaneously. It combines elite chemical resistance, a vast operational temperature range, and crucial mechanical flexibility, making it an indispensable component for protecting the integrity and longevity of demanding piping systems.

The true value of PTFE bellows lies not in a single feature, but in their holistic performance. They provide a reliable, long-term solution for managing thermal expansion, vibration, and misalignment in environments where virtually any other material would quickly corrode or fail.

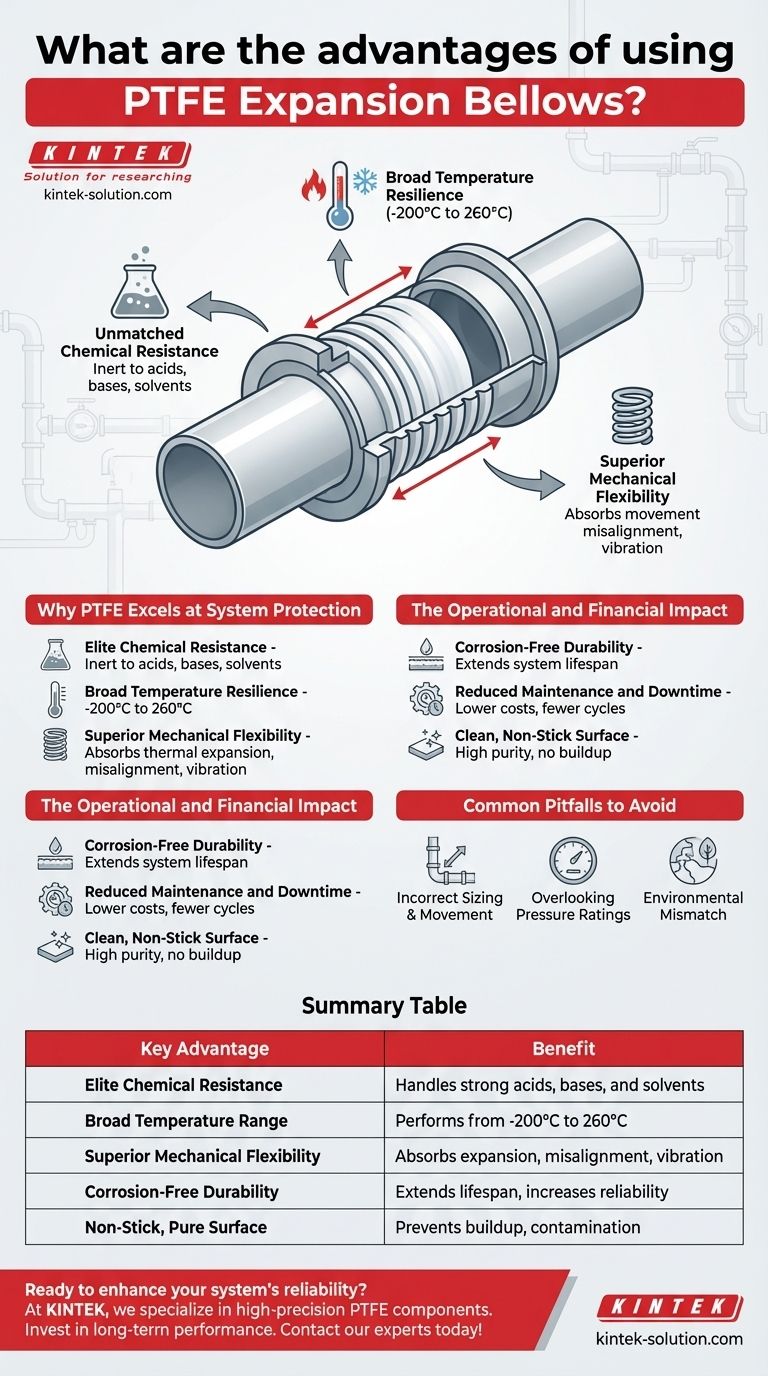

Why PTFE Excels at System Protection

The choice of Polytetrafluoroethylene (PTFE) is deliberate. Its molecular structure gives it a set of properties that are almost perfectly suited for the dynamic and often hostile environments found in industrial piping.

Unmatched Chemical Resistance

A PTFE bellow is practically inert to almost all industrial chemicals. It can safely handle highly corrosive media, including strong acids, bases, and aggressive solvents, without degrading.

This chemical stability prevents contamination of the process fluid and protects the bellow itself from being eaten away, which is a common failure point for metal or rubber alternatives.

Broad Temperature Resilience

PTFE performs reliably across an exceptionally wide temperature spectrum, typically from -200 °C to 260 °C (-328 °F to 500 °F).

This makes it an ideal choice for systems that experience extreme cold, high heat, or rapid thermal cycling, ensuring consistent performance where other materials would become brittle or lose structural integrity.

Superior Mechanical Flexibility

The fundamental purpose of an expansion bellow is to absorb movement and relieve stress. PTFE excels at this by compensating for three primary issues:

- Thermal Expansion: It absorbs the growth and shrinkage of pipes as temperatures change.

- Misalignment: It corrects for minor offsets in the piping installation.

- Vibration: It dampens harmful vibrations from pumps, motors, and other equipment, protecting the entire system.

The Operational and Financial Impact

Choosing the right component goes beyond technical specifications; it directly impacts your budget, maintenance schedule, and operational uptime.

Corrosion-Free Durability

Because PTFE is chemically inert, it does not rust or corrode. This quality extends the lifespan not only of the bellow but of the entire piping system by creating a protective barrier.

The result is a significant increase in system longevity and reliability.

Reduced Maintenance and Downtime

The inherent durability and resistance to chemical attack mean PTFE bellows fail far less frequently than other materials in corrosive environments.

This directly translates to lower maintenance costs, fewer replacement cycles, and most importantly, a drastic reduction in costly, unplanned operational downtime.

Clean, Non-Stick Surface

PTFE has an extremely low coefficient of friction, creating a "non-stick" surface. This property is critical in processes where purity and flow are paramount.

It prevents material buildup, ensures smooth and efficient fluid transfer, and minimizes the risk of contamination, making it essential for the pharmaceutical, food and beverage, and semiconductor industries.

Common Pitfalls to Avoid

The advantages of PTFE are only realized through correct specification and installation. A failure to account for system parameters can undermine the component's effectiveness.

Incorrect Sizing and Movement

You must accurately specify the required internal diameter, length, and the precise types of movement the bellow needs to absorb (e.g., axial compression, lateral offset). An underspecified bellow will fail under stress.

Overlooking Pressure Ratings

Every bellow has a defined pressure limit that often changes with temperature. Operating outside these specified pressure-temperature ratings is a primary cause of premature failure.

Environmental Mismatch

While chemically robust, you must still consider the external environment. Factors like potential for high UV exposure or external physical impact should be accounted for in the system design to ensure long-term reliability.

Making the Right Choice for Your Goal

To select the correct bellow, anchor your decision in the primary problem you need to solve.

- If your primary focus is handling highly corrosive media: PTFE is the default choice due to its near-universal chemical inertness, which guarantees system and product integrity.

- If your primary focus is ensuring absolute product purity: The non-stick, non-leaching properties of PTFE make it essential for pharmaceutical, food-grade, or semiconductor applications.

- If your primary focus is protecting equipment from vibration: PTFE's ability to absorb shock and dampen vibration is key to extending the life of pumps, meters, and other sensitive components.

- If your primary focus is reducing long-term operational costs: The exceptional durability and low maintenance requirements of PTFE bellows offer a superior total cost of ownership compared to less robust materials.

Ultimately, selecting a PTFE expansion bellow is an investment in your system's long-term stability and reliability.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Elite Chemical Resistance | Handles strong acids, bases, and solvents without degradation. |

| Broad Temperature Range | Performs reliably from -200°C to 260°C (-328°F to 500°F). |

| Superior Mechanical Flexibility | Absorbs thermal expansion, misalignment, and vibration. |

| Corrosion-Free Durability | Extends system lifespan and increases reliability. |

| Non-Stick, Pure Surface | Prevents material buildup and contamination for sensitive industries. |

Ready to enhance your system's reliability and reduce downtime?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution perfectly tailored to handle your specific chemical, temperature, and mechanical challenges—from prototype to high-volume production.

Invest in long-term performance. Contact our experts today for a consultation on your custom PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications