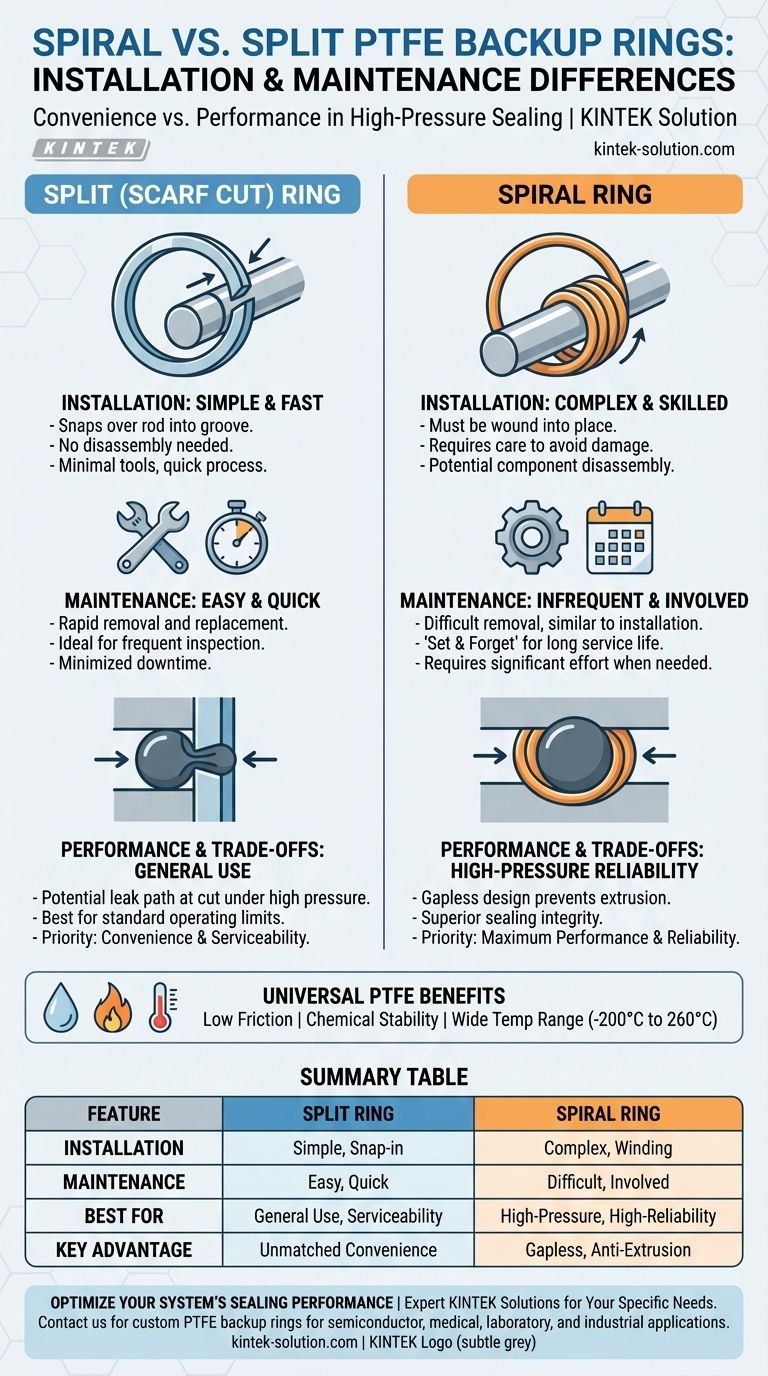

The fundamental difference between installing spiral and split PTFE backup rings stems directly from their physical design. A split ring features a cut that allows it to be easily snapped into a groove, while a continuous spiral ring must be carefully wound or stretched into place, making its installation more complex. This design distinction dictates not only the installation procedure but also the ease and frequency of subsequent maintenance.

The choice is a direct trade-off between convenience and performance. Split rings offer unparalleled ease of installation and maintenance for general use, while spiral rings provide superior, gapless sealing integrity required for more demanding, high-pressure applications.

The Installation Process: A Tale of Two Designs

The installation method for each ring type is the most immediate and practical difference you will encounter. It directly impacts assembly time, the skill required, and the potential for component damage.

Installing the Split (Scarf Cut) Ring

A split ring, often called a scarf cut ring, is designed for simplicity. Its single cut along the circumference allows the ring to be expanded.

This flexibility means it can be easily snapped over a rod or compressed into a cylinder groove without requiring the full disassembly of surrounding components. The process is fast, straightforward, and requires minimal specialized tooling.

Installing the Spiral Ring

A spiral ring is a continuous coil of PTFE with no gap. This design is key to its performance but complicates its installation.

The ring cannot be simply snapped into place. Instead, it must be carefully "wound" into the groove, a process that requires more time and skill to avoid over-stretching or damaging the material. In many cases, it necessitates more significant equipment disassembly to gain access to the groove.

Maintenance and System Accessibility

The initial installation complexity has long-term implications for system maintenance, inspection, and total cost of ownership.

The Advantage of Split Rings for Maintenance

The ease of installing a split ring translates directly to ease of removal. This is a significant advantage in systems that require frequent inspection or seal replacement.

Maintenance can be performed quickly, minimizing equipment downtime. If a primary seal fails, replacing the backup ring is a simple and efficient task.

The "Set and Forget" Nature of Spiral Rings

Spiral rings are chosen for applications where reliability is paramount and maintenance is expected to be infrequent. Their superior sealing performance is intended to extend the service life of the component.

However, when maintenance is eventually required, the process is more involved. The same challenges faced during installation—the need for careful handling and potential component disassembly—reappear during removal and replacement.

Understanding the Trade-offs: Why Choose One Over the Other?

The differences in installation and maintenance are not arbitrary; they are a direct result of designing for different performance requirements.

Performance: Uniform Pressure vs. a Potential Leak Path

The spiral ring's continuous, gapless design is its greatest strength. It provides completely uniform support to the O-ring or seal, offering the best protection against seal extrusion under high pressure.

The cut in a split ring, while convenient, creates a potential extrusion path. Under very high pressures, the primary seal can be forced into this small gap, leading to premature failure.

Application Demands: High-Pressure vs. General Use

Because of its robust, gapless design, the spiral ring is the preferred choice for demanding hydraulic and pneumatic systems where pressure spikes and dynamic motion are common.

The split ring is a versatile workhorse, perfectly suited for a vast range of static and dynamic applications where convenience and serviceability are priorities and pressures are within standard operating limits.

The Universal Benefits of PTFE

Regardless of the design, both rings leverage the exceptional properties of PTFE. This material provides an extremely low friction coefficient, outstanding chemical stability, and functionality across a wide temperature range (from -200°C to 260°C).

Making the Right Choice for Your Application

Your decision should be guided by the specific operational demands and maintenance strategy for your equipment.

- If your primary focus is maximum sealing performance and system reliability in a high-pressure environment: Choose the spiral backup ring, as its continuous design offers the best protection against seal extrusion.

- If your primary focus is ease of assembly, quick maintenance, and reducing downtime in accessible systems: The split (scarf cut) backup ring is the superior choice for its installation convenience.

- If your system operates in corrosive chemical environments or at extreme temperatures: Both types are excellent choices, so base your decision on the system's pressure and maintenance requirements.

Ultimately, understanding this balance between performance integrity and practical serviceability is the key to selecting the correct backup ring for your design.

Summary Table:

| Feature | Spiral Ring | Split (Scarf Cut) Ring |

|---|---|---|

| Installation | Complex; requires winding/stretching into groove | Simple; snaps directly into place |

| Maintenance | Difficult; often requires significant disassembly | Easy; allows for quick inspection and replacement |

| Best For | High-pressure, high-reliability applications | General use, serviceability-focused systems |

| Key Advantage | Gapless design prevents seal extrusion | Unmatched convenience and reduced downtime |

Optimize Your System's Sealing Performance

Choosing the right PTFE backup ring is critical for your application's reliability and maintenance schedule. The experts at KINTEK specialize in manufacturing precision PTFE components, including custom spiral and split backup rings, for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your pressure, chemical, and temperature requirements.

Let our expertise guide your design. Contact KINTEB today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are extruded PTFE rods popular in plumbing systems? Superior Chemical & Thermal Resistance

- How can PTFE lined butterfly valves be customized for different applications? Tailor Valves for Your Specific Needs

- How are PTFE lip seals used in industrial applications? Solving Extreme Sealing Challenges

- What are the overall advantages of using PTFE bellows? Superior Chemical Resistance & Purity

- How can Teflon PTFE sheets be used in heat press applications? Protect Your Designs and Equipment

- What are the five main advantages of PTFE O-rings? Superior Sealing for Harsh Environments

- What are the structural differences between PTFE lined and hard seal butterfly valves? A Guide to Sealing Mechanisms

- What are the benefits of using PTFE valves in the food processing industry? Ensure Safety, Purity, and Efficiency