Selecting the right expanded PTFE gasket requires a systematic evaluation of your application's specific demands. The primary factors you must consider are the chemical compatibility of the media being sealed, the operating temperature and pressure ranges, and the physical condition of the flange surfaces. These elements work together to determine the integrity and longevity of the seal.

The core challenge is not just knowing that expanded PTFE (ePTFE) is a high-performance material, but understanding how to match its specific properties—like density and thickness—to the precise mechanical and chemical stresses of your operating environment.

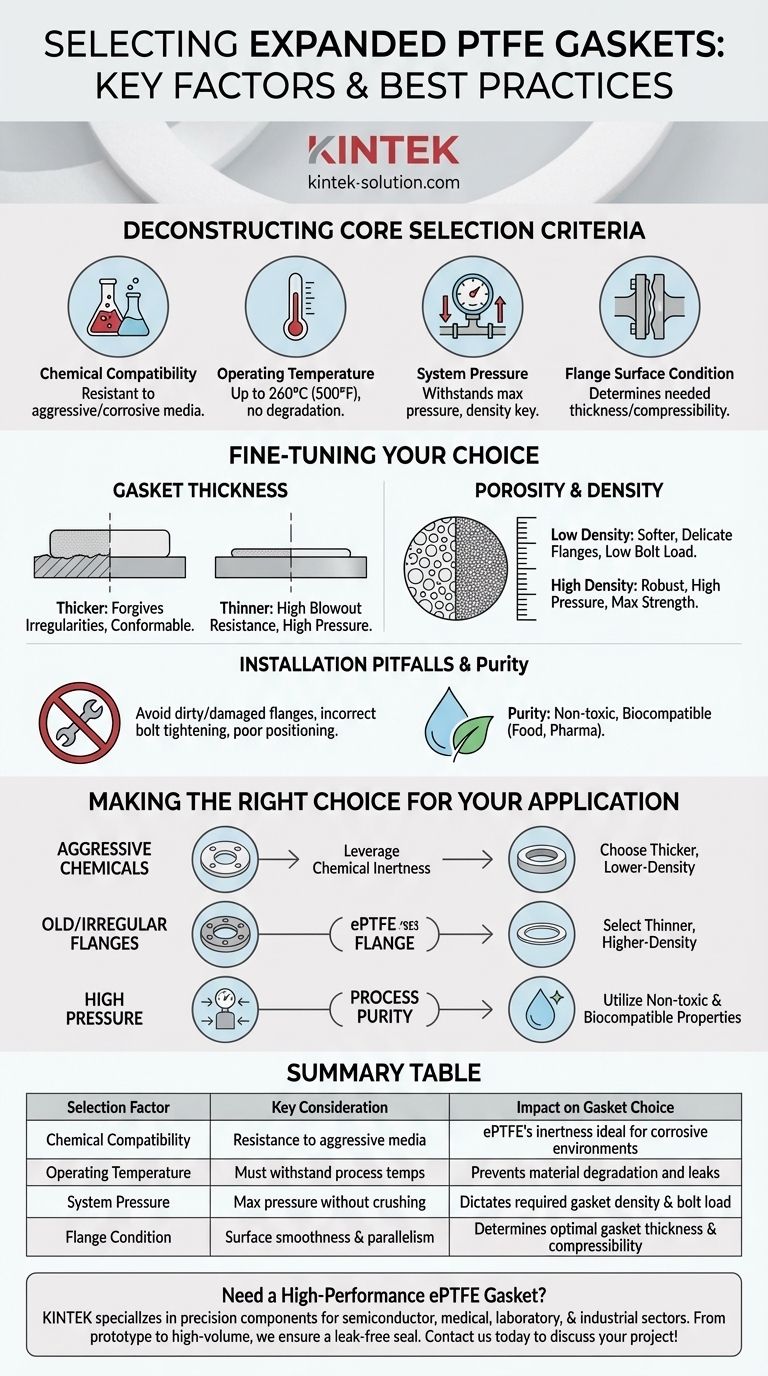

Deconstructing the Core Selection Criteria

To ensure a reliable, leak-free seal, you must analyze the four fundamental conditions of your application. Each factor directly influences the performance and suitability of an ePTFE gasket.

Chemical Compatibility

Expanded PTFE is known for its exceptional chemical inertness, making it resistant to nearly all industrial chemicals. This makes it a default choice for applications involving aggressive or corrosive media where other materials would quickly degrade.

Operating Temperature Range

You must select a gasket rated for the full temperature spectrum of your process, including any potential spikes. ePTFE maintains its integrity and sealing capability at high temperatures, typically up to 260°C (500°F), preventing material degradation and subsequent leaks.

System Pressure

The gasket must withstand the maximum system pressure without being crushed or extruded from the flange. The gasket's ability to resist this force is directly related to its density and the available bolt load used to compress it.

Flange Surface Condition

This is a frequently overlooked but critical factor. Perfectly smooth, parallel flanges require a different gasket than older, warped, or scarred surfaces. The condition of your flanges will dictate the necessary thickness and compressibility of the gasket.

Beyond the Basics: Fine-Tuning Your Gasket Choice

Once the core criteria are met, you can refine your selection by considering the specific properties of the ePTFE material itself. These nuances are what separate an adequate seal from an optimal one.

The Role of Gasket Thickness

Thickness is a balancing act. Thicker gaskets are more forgiving and can better fill in surface irregularities on worn or uneven flanges. However, thinner gaskets offer higher blowout resistance and are better suited for high-pressure applications where flange surfaces are in good condition.

Understanding Porosity and Density

ePTFE is available in different densities (often categorized as low, medium, and high). Low-density ePTFE is softer and more compressible, making it ideal for delicate flanges (like glass-lined steel) or applications with low available bolt load. High-density ePTFE is more robust and better suited for high-pressure environments that require maximum seal strength.

Purity and Biocompatibility

For industries like pharmaceuticals, food and beverage, or medical devices, material purity is non-negotiable. ePTFE is inherently non-toxic, non-allergenic, and biocompatible, ensuring it will not contaminate the process media.

Understanding the Trade-offs and Installation Pitfalls

Even the perfect material can fail if its limitations are not understood or if it is installed improperly. A successful outcome depends on both correct selection and correct application.

ePTFE is Not a Universal Solution

While incredibly versatile, ePTFE is a premium material. Its selection must be justified by application requirements like extreme chemical exposure or high temperatures. For less demanding services, other materials might offer a more cost-effective solution.

Installation is as Critical as Selection

A high-quality gasket will fail if installed poorly. The most common mistakes include using dirty or damaged flange surfaces, incorrect bolt tightening procedures, and improper gasket positioning. Always ensure flanges are clean, and tighten bolts in a star or crisscross pattern to apply even pressure.

Making the Right Choice for Your Application

Use your specific operational goal to guide your final decision. By matching the gasket's properties to your primary challenge, you ensure optimal performance and long-term reliability.

- If your primary focus is aggressive chemicals: Rely on ePTFE's inherent chemical inertness as its key advantage.

- If your primary focus is sealing old or irregular flanges: Choose a thicker, lower-density ePTFE gasket for its superior conformability.

- If your primary focus is withstanding high pressure: Select a thinner, higher-density ePTFE gasket for maximum strength and blowout resistance.

- If your primary focus is maintaining process purity: Leverage ePTFE's non-toxic and biocompatible properties for food, pharma, or medical applications.

Ultimately, a methodical approach to gasket selection transforms it from a simple component choice into a critical step for ensuring system safety and efficiency.

Summary Table:

| Selection Factor | Key Consideration | Impact on Gasket Choice |

|---|---|---|

| Chemical Compatibility | Resistance to aggressive media | ePTFE's inertness makes it ideal for corrosive environments |

| Operating Temperature | Must withstand process temperatures (up to 260°C/500°F) | Prevents material degradation and leaks |

| System Pressure | Maximum pressure without crushing/extrusion | Dictates required gasket density and bolt load |

| Flange Condition | Surface smoothness and parallelism | Determines optimal gasket thickness and compressibility |

Need a high-performance ePTFE gasket tailored to your exact application? KINTEK specializes in manufacturing precision expanded PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard solution or a custom fabrication—from prototype to high-volume production—our expertise ensures a leak-free seal that withstands your specific chemical, temperature, and pressure demands. Contact our team today to discuss your project and receive a solution that guarantees system safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What pressure considerations apply to PTFE lined butterfly valves? Avoid Liner Failure and Ensure Safe Operation

- What cost benefits do PTFE oil seals offer? Slash Your Total Cost of Ownership

- What considerations are important when selecting Teflon for CNC machining? Master Its Unique Challenges

- What are PTFE lined butterfly valves? A Guide to Corrosive Fluid Control

- What are the limitations of Teflon encapsulated O-rings in terms of chemical resistance? Key Weaknesses to Avoid Seal Failure

- What temperature range can PTFE envelope gaskets withstand? -200°C to +260°C for Extreme Conditions

- What makes PTFE chemically resistant? The Power of Fluorine's Protective Shield

- What materials are used for hydraulic and pneumatic sealing? Choose the Right Seal for Extreme Conditions