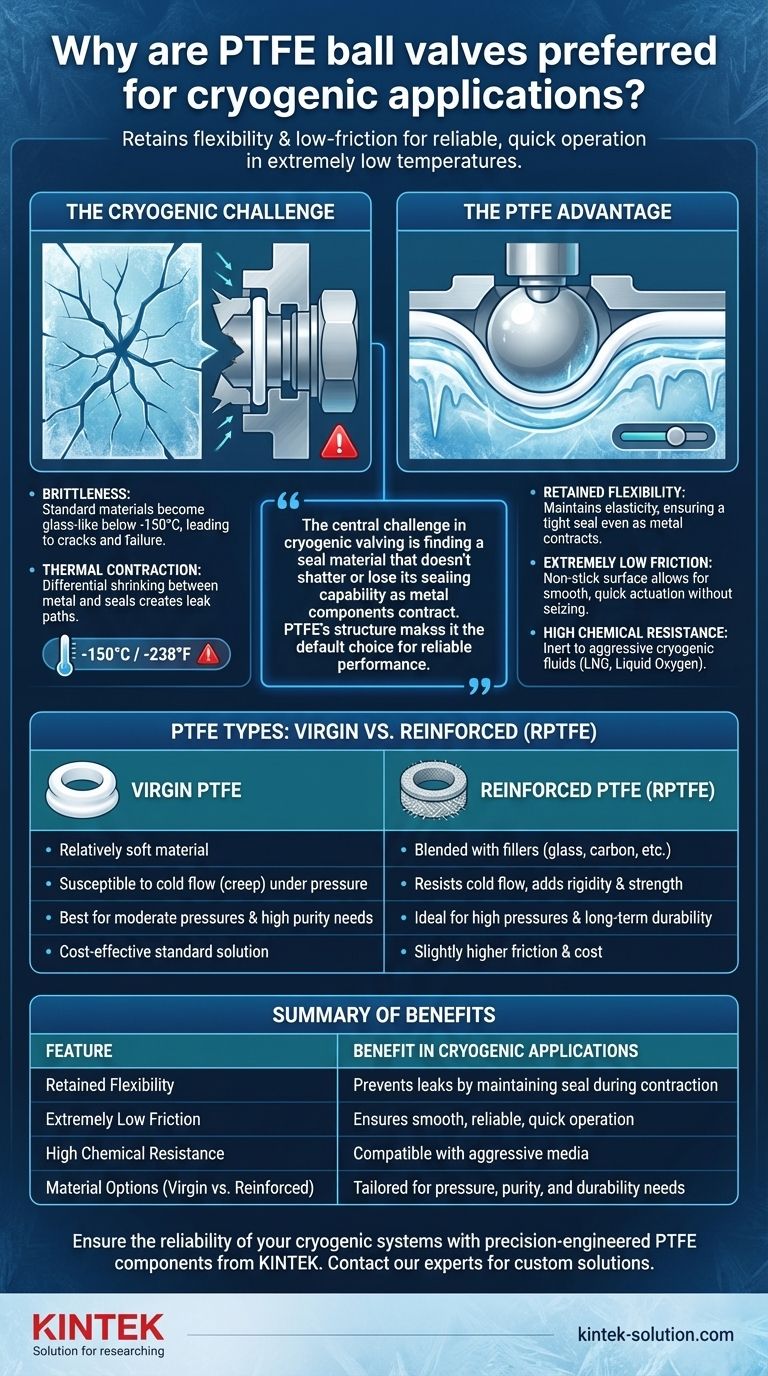

In cryogenic applications, PTFE is the preferred seating material for ball valves because it uniquely retains the necessary flexibility and low-friction properties at extremely low temperatures. This ensures a reliable seal and smooth, quick operation where other common sealing materials would become brittle and fail.

The central challenge in cryogenic valving is finding a seal material that doesn't shatter or lose its sealing capability as metal components contract in the cold. PTFE's molecular structure allows it to maintain sealing integrity and a non-stick surface, making it the default choice for reliable performance.

Why Standard Materials Fail in Cryogenic Conditions

To understand why PTFE excels, it's crucial to first recognize the immense challenges posed by cryogenic temperatures (typically below -150°C / -238°F).

The Problem of Brittleness

Most elastomers and plastics, like rubber or standard nylon, undergo a phase transition at low temperatures. They lose their flexibility and become extremely brittle, like glass.

Any operational stress or pressure fluctuation on a brittle seal would cause it to crack or shatter, leading to a catastrophic leak.

The Challenge of Thermal Contraction

All materials shrink when cooled. The metal body and ball of a valve will contract at a different rate than the seals.

This differential contraction can create gaps, opening up leak paths. A successful seal material must be able to compensate for this shrinkage to maintain constant, tight contact with the valve components.

The Unique Advantages of PTFE at Low Temperatures

PTFE (Polytetrafluoroethylene) possesses a rare combination of properties that directly solve the core problems of cryogenic sealing.

Retained Flexibility for a Tight Seal

Unlike other plastics, PTFE does not become brittle at cryogenic temperatures. It retains enough flexibility and elasticity to conform to the metal surfaces of the valve.

This allows the PTFE seat to maintain a tight seal against the ball, even as the valve body contracts, preventing leaks.

Extremely Low Friction for Smooth Operation

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This non-stick characteristic is critical at low temperatures.

It ensures the valve can be opened and closed quickly ("quick action") without the ball seizing or sticking to the seats, which could be coated in frozen media. This guarantees reliable actuation when needed.

High Chemical Resistance

While the primary challenge in cryogenics is temperature, the media being handled (like LNG or liquid oxygen) can still be reactive. PTFE is nearly chemically inert, making it compatible with a vast range of aggressive and pure fluids.

Understanding the Trade-offs: Virgin vs. Reinforced PTFE

While PTFE is the superior choice, it is not a perfect material. Understanding its main limitation is key to proper valve specification.

The Limitation of Virgin PTFE: Cold Flow

Standard, or "virgin," PTFE is a relatively soft material. Under sustained pressure and temperature fluctuations, it can slowly deform over time.

This phenomenon, known as cold flow or creep, can eventually degrade the quality of the seal, especially in high-pressure applications.

The Solution: Reinforced PTFE (RPTFE)

To combat cold flow, PTFE is often blended with filler materials. This creates a composite known as Reinforced PTFE (RPTFE).

Common fillers include glass fiber, carbon, graphite, or bronze. These materials add rigidity and structural stability to the PTFE, drastically improving its resistance to deformation and wear.

Impact on Performance

Reinforcing PTFE improves its strength and durability, making it suitable for higher pressures and extending its service life. The trade-off is a slight increase in friction and cost, but for demanding applications, the benefits in reliability are substantial.

Making the Right Choice for Your Goal

The choice between virgin and reinforced PTFE depends entirely on the specific demands of your system.

- If your primary focus is high-pressure service or long-term durability: Reinforced PTFE (RPTFE) is essential to resist deformation and ensure a longer, more reliable service life.

- If your primary focus is moderate pressures in standard applications: Virgin PTFE provides all the core low-temperature benefits and is often a sufficient and cost-effective solution.

- If your primary focus is preventing media contamination (e.g., food or pharma): Virgin PTFE is typically specified due to its purity and lack of filler materials.

Ultimately, understanding the properties of PTFE empowers you to specify a valve that delivers safety and reliability in the most demanding cryogenic systems.

Summary Table:

| Feature | Benefit in Cryogenic Applications |

|---|---|

| Retained Flexibility | Maintains a tight seal, preventing leaks even as metal components contract |

| Extremely Low Friction | Ensures smooth, quick operation without seizing or sticking |

| High Chemical Resistance | Compatible with aggressive cryogenic fluids like LNG and liquid oxygen |

| Material Options (Virgin vs. Reinforced) | Can be tailored for specific needs like purity, pressure, or durability |

Ensure the reliability and safety of your cryogenic systems with precision-engineered PTFE components from KINTEK.

Whether you are handling LNG, liquid oxygen, or other ultra-cold media in the semiconductor, medical, laboratory, or industrial sectors, the right valve seating material is critical. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware designed to perform flawlessly under extreme conditions.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a solution tailored to your specific pressure, purity, and durability requirements.

Contact our experts today to discuss your application and discover how our PTFE components can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites