In demanding industrial environments, Polytetrafluoroethylene (PTFE) spherical balls are most commonly used in chemical handling pumps, check valves, light-load ball bearings, and as volume displacement media in chemical baths. Their selection is driven by a unique set of material properties that outperform other materials in highly specific conditions.

The decision to use a PTFE ball is almost always driven by its exceptional chemical resistance and inherent lubricity. It solves problems where traditional materials would corrode, seize, or contaminate a process, especially in fluid handling and light-load mechanical systems.

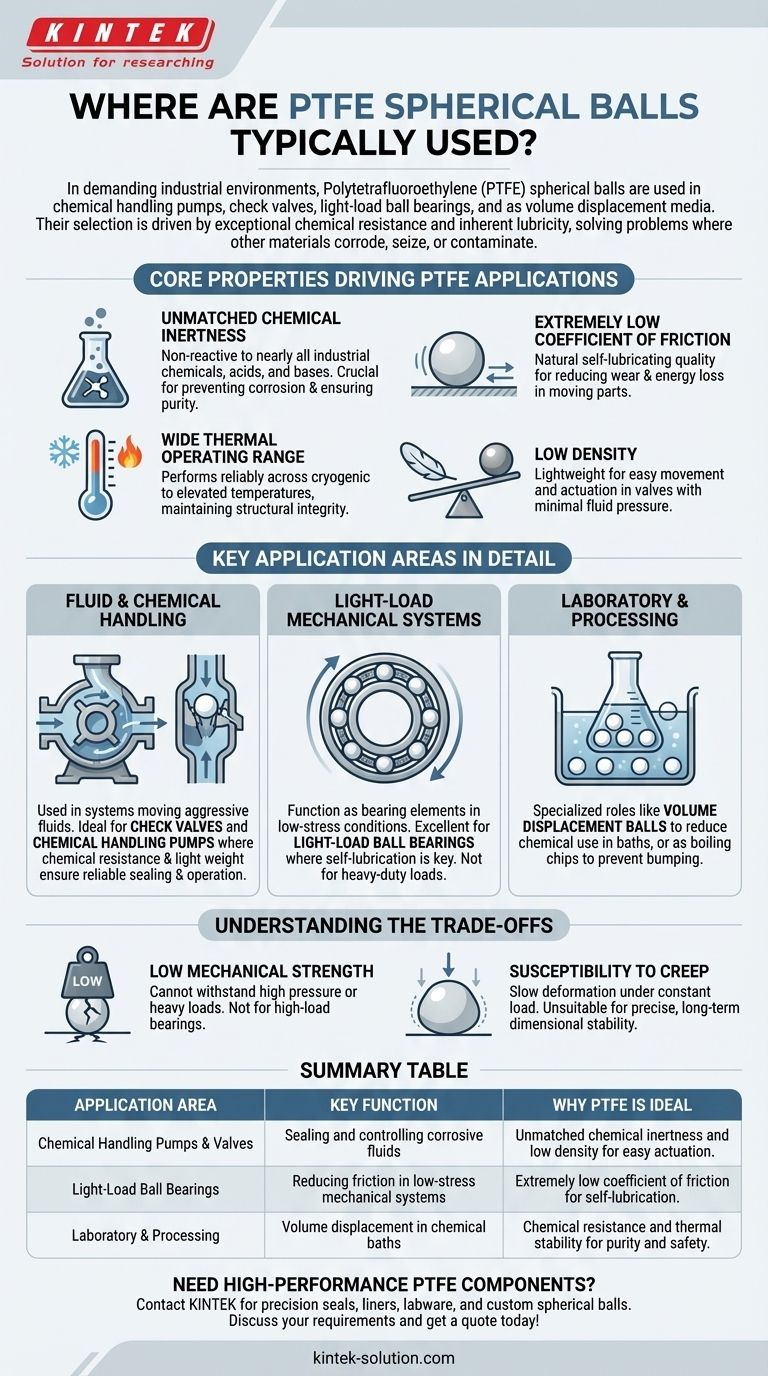

The Core Properties Driving PTFE Ball Applications

To understand where PTFE balls are used, you must first understand why they are chosen. The applications are a direct result of the material's fundamental characteristics.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and bases. This makes it an essential material in aggressive environments.

This property is critical in industries like chemical processing, pharmaceuticals, and food manufacturing, where preventing corrosion and maintaining product purity are paramount.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a natural self-lubricating quality.

This inherent "slipperiness" is ideal for applications involving moving parts, such as seals and bearings, where reducing wear and energy loss is a key objective.

Wide Thermal Operating Range

PTFE performs reliably across a very broad spectrum of temperatures.

It maintains its structural integrity and key properties in both cryogenic conditions and elevated heat, a versatility that few other polymers can match.

Low Density

Compared to metal or ceramic balls, PTFE balls are very lightweight.

This low density makes them suitable for applications like check valves, where the ball needs to move easily to open or seal the valve with minimal fluid pressure.

Key Application Areas in Detail

These core properties make PTFE balls the optimal choice for several specific industrial and scientific roles.

In Fluid and Chemical Handling

The most common use for PTFE balls is within systems that move, control, or contain aggressive fluids.

Applications include check valves (non-return valves), where the ball's light weight and chemical resistance create a reliable seal, and chemical handling pumps, where components must withstand constant exposure to corrosive media.

In Light-Load Mechanical Systems

PTFE balls are frequently used as bearing elements in low-stress conditions.

They function exceptionally well in light-load ball bearings where self-lubrication is more important than high strength. They are not suitable for heavy-duty applications where steel or ceramic balls would be required.

In Laboratory and Processing

In scientific and manufacturing settings, PTFE balls serve specialized functions.

They are used as volume displacement balls in chemical baths to reduce the required volume of expensive or hazardous chemicals. They can also be used as "boiling chips" to prevent bumping during the boiling of liquids in a lab.

Understanding the Trade-offs

While its advantages are significant, PTFE is not universally applicable. Understanding its limitations is crucial for proper selection.

Low Mechanical Strength

The primary trade-off is PTFE's softness and low mechanical strength compared to metals or ceramics.

It cannot withstand high pressure or heavy structural loads. Using a PTFE ball in a high-load bearing would lead to rapid deformation and failure.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time—a phenomenon known as creep.

This makes it unsuitable for applications that require precise, long-term dimensional stability under mechanical stress.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to your primary operational goal.

- If your primary focus is handling corrosive fluids: PTFE is an ideal choice for components like check valves and pump balls due to its unparalleled chemical inertness.

- If your primary focus is low-friction movement under light loads: PTFE balls excel in bearings and seals where self-lubrication is critical and mechanical stress is minimal.

- If your primary focus is high-load structural support: You must look to other materials like stainless steel or ceramic, as PTFE lacks the required mechanical strength.

Choosing PTFE is a strategic decision for environments where chemical resilience and low friction are the most critical performance factors.

Summary Table:

| Application Area | Key Function | Why PTFE is Ideal |

|---|---|---|

| Chemical Handling Pumps & Valves | Sealing and controlling corrosive fluids | Unmatched chemical inertness and low density for easy actuation |

| Light-Load Ball Bearings | Reducing friction in low-stress mechanical systems | Extremely low coefficient of friction for self-lubrication |

| Laboratory & Processing | Volume displacement in chemical baths | Chemical resistance and thermal stability for purity and safety |

Need high-performance PTFE components for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom spherical balls—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures a solution that delivers superior chemical resistance and reliability.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How can fillers improve the performance of PTFE O-Rings? Enhance Strength, Wear, and Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What makes PTFE washers ideal for high and low temperature applications? Ensuring Reliable Performance in Extreme Environments

- How does PTFE's electrical insulation benefit medical devices? Ensuring Safety and Reliability in Critical Applications

- What makes PTFE suitable for custom industrial parts? Discover the Ideal Material for Harsh Environments

- What industries commonly use PTFE butterfly valves and why? For Superior Chemical Resistance & Purity

- Why is the high-temperature tolerance of PTFE gaskets important? Ensure Reliable Sealing in Extreme Heat

- What factors should be considered when choosing between PTFE and graphite braided packing? Select the Right Seal for Your Application