In short, PTFE butterfly valves are the go-to solution for industries where product purity and chemical resistance are non-negotiable. They are most commonly used in chemical processing, pharmaceuticals, food and beverage, and oil and gas due to PTFE's unparalleled ability to handle corrosive substances, prevent contamination, and withstand harsh operating conditions.

The decision to use a PTFE butterfly valve is driven by the material itself. Industries don't choose the valve; they choose PTFE's unique combination of chemical inertness, purity, and durability to protect their processes, products, and personnel.

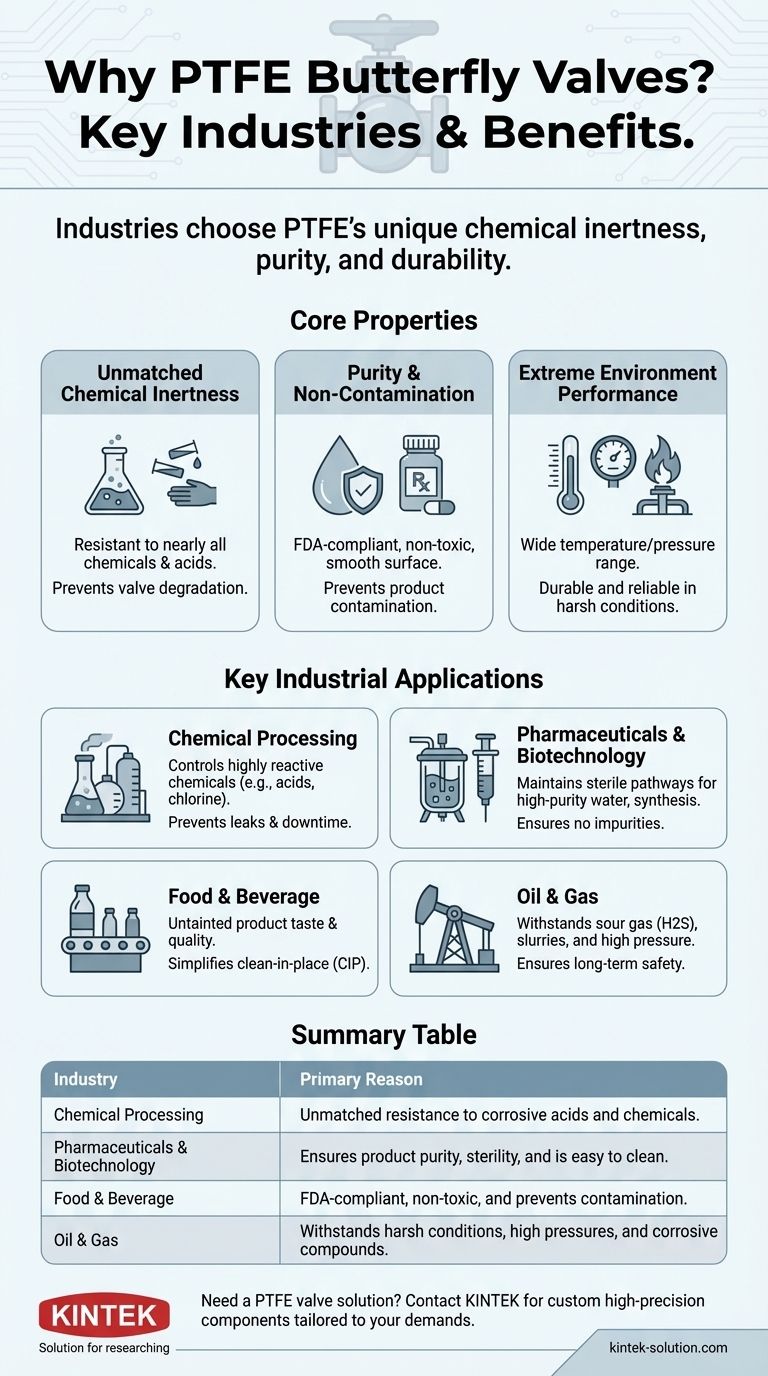

The Core Properties Driving Adoption

The widespread use of PTFE-lined valves isn't accidental. It's a direct result of the material's fundamental characteristics, which solve critical challenges in demanding industrial environments.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and corrosive agents. This makes it an essential material for safely handling aggressive substances without the risk of valve degradation or failure.

This property is the primary reason for its dominance in the chemical processing industry, where it is used to line pipes, vessels, and valves that are in constant contact with harsh materials.

Purity and Non-Contamination

PTFE is biologically inert, non-toxic, and FDA-compliant. Its surface is exceptionally smooth and non-stick, which prevents media from adhering to it and minimizes the risk of bacterial growth.

This is critical for the pharmaceutical and food and beverage industries, where preventing product contamination is the highest priority. It also allows for effective sterilization processes.

Performance in Extreme Environments

PTFE maintains its properties across a wide range of temperatures and pressures. This durability ensures reliable performance and a tight seal, even in the demanding conditions found in many industrial settings.

The oil and gas sector relies on this robustness for handling high-pressure fluids and corrosive compounds commonly found in exploration, transportation, and refining processes.

A Closer Look at Key Industrial Applications

Understanding the "why" behind PTFE's selection becomes clearer when looking at specific use cases within these key industries.

Chemical Processing

In this sector, PTFE butterfly valves are used to control the flow of substances like sulfuric acid, chlorine, and other highly reactive chemicals. A standard metal valve would corrode and fail quickly, leading to dangerous leaks and costly downtime.

Pharmaceuticals & Biotechnology

Maintaining sterile pathways is paramount. PTFE-lined valves are used in high-purity water systems (WFI), chemical synthesis, and bioreactors to ensure no impurities leach into the final product and that the valve surfaces can be thoroughly cleaned and sterilized.

Food and Beverage

From dairy processing to beverage manufacturing, PTFE valves ensure that the product's taste and quality remain untainted. Their non-stick nature also simplifies clean-in-place (CIP) procedures, improving operational efficiency and hygiene.

Oil and Gas

Valves in this industry must withstand corrosive sour gas (H2S), abrasive slurries, and high-pressure injection chemicals. PTFE provides the necessary resilience to ensure long-term operational safety and integrity in these harsh applications.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Cold Flow

PTFE can be subject to "creep" or cold flow, meaning it can slowly deform over time under constant pressure. Valve designs must account for this characteristic to maintain a long-lasting, leak-proof seal.

Higher Thermal Expansion

Compared to metals, PTFE has a high coefficient of thermal expansion. This means it expands and contracts more significantly with temperature changes, a factor that engineers must manage in valve construction for applications with wide thermal cycles.

Cost Considerations

PTFE-lined components are a premium product. They are more expensive than valves made from standard materials, making them a strategic choice for critical applications rather than general-purpose use.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your process environment.

- If your primary focus is handling highly corrosive chemicals: PTFE's unmatched chemical inertness provides the most reliable protection against valve failure and hazardous leaks.

- If your primary focus is product purity and hygiene: PTFE's FDA-compliant, non-contaminating, and non-stick properties are essential for any pharmaceutical or food-grade application.

- If your primary focus is performance in harsh environments: The durability and wide operating temperature range of PTFE make it a superior choice for demanding sectors like oil and gas.

Ultimately, selecting a PTFE butterfly valve is an investment in operational safety, product integrity, and long-term reliability.

Summary Table:

| Industry | Primary Reason for Using PTFE Butterfly Valves |

|---|---|

| Chemical Processing | Unmatched resistance to corrosive acids and chemicals. |

| Pharmaceuticals & Biotechnology | Ensures product purity, sterility, and is easy to clean. |

| Food & Beverage | FDA-compliant, non-toxic, and prevents contamination. |

| Oil & Gas | Withstands harsh conditions, high pressures, and corrosive compounds. |

Need a PTFE valve solution tailored to your industry's unique demands?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom butterfly valves, for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication—from prototypes to high-volume orders—to deliver the reliability, purity, and chemical resistance your critical applications require.

Contact KINTEK today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What happens to the PTFE material when pressure is applied to the sealing ring? It Deforms to Create a Superior Seal

- How does a teflon check valve impact industrial operations? Boost Uptime & Protect Purity

- What are some industrial applications of PTFE seals? Solve Your Toughest Sealing Challenges

- What cooling and lubrication techniques are recommended for PTFE machining? Master Heat Control for Precision Parts

- What materials are commonly used to fortify PTFE seals? Enhance Performance with Glass, Carbon, Graphite & Bronze

- What is PTFE and why is it used in mechanical seals? Unmatched Chemical Resistance & Low Friction

- In what industries or applications are PTFE bellows commonly used? Essential for Purity and Corrosion Resistance

- What makes FEP and PTFE encapsulated O-rings suitable for chemical processing? Achieve Leak-Free Sealing in Corrosive Environments