At their core, FEP and PTFE encapsulated O-rings are suitable for chemical processing because they combine the superior chemical inertness of a fluoropolymer shell with the reliable elasticity of an inner core. This dual-material design creates a seal that is nearly impervious to chemical attack from acids, bases, and solvents, preventing degradation and failure in the most demanding environments.

The central advantage of an encapsulated O-ring is that it offers the best of two worlds: the robust, physical sealing force of a traditional elastomeric O-ring and the near-universal chemical and temperature resistance of a PTFE or FEP outer jacket.

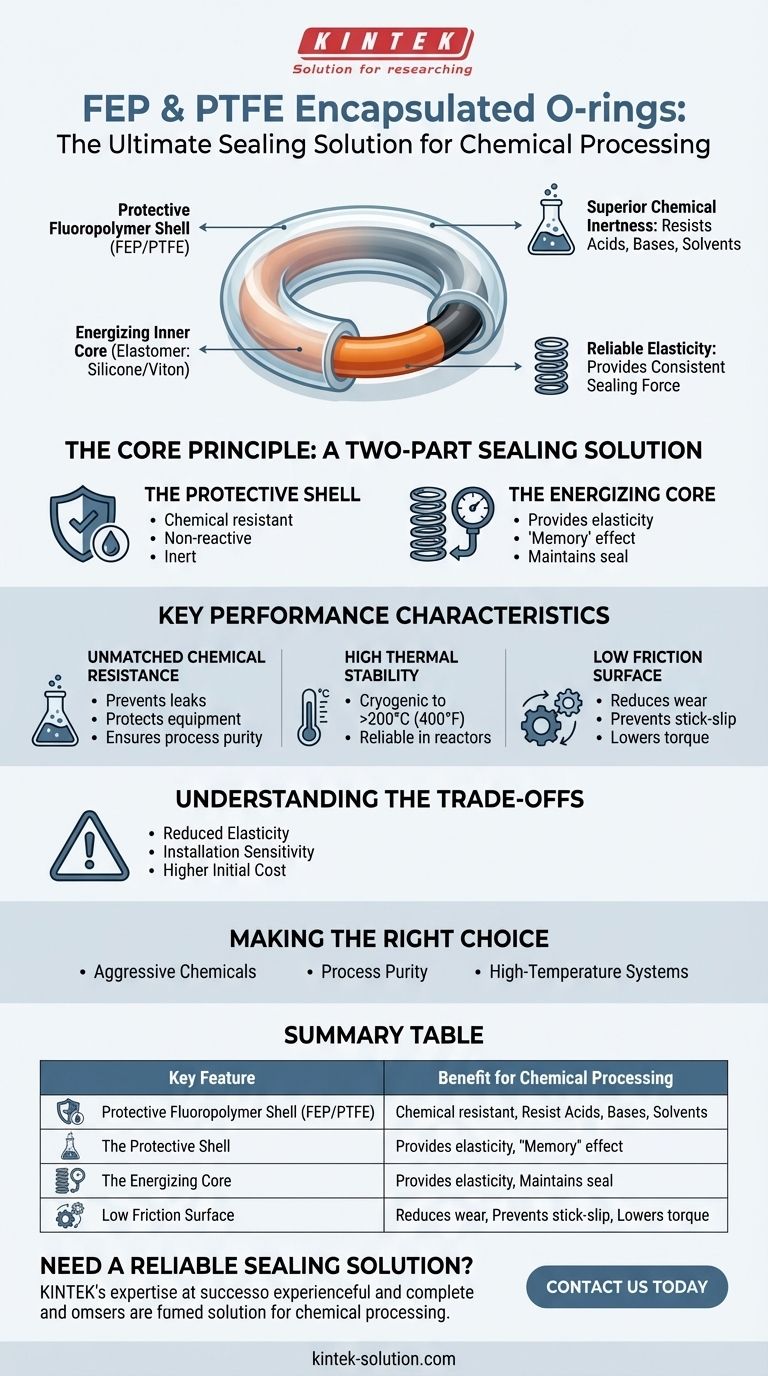

The Core Principle: A Two-Part Sealing Solution

To understand their effectiveness, you must see encapsulated O-rings not as a single material, but as a system. The design solves a fundamental engineering problem.

The Protective Fluoropolymer Shell

The outer jacket is made from either PTFE (Polytetrafluoroethylene) or FEP (Fluorinated Ethylene Propylene). This layer is what comes into direct contact with the process media.

As a material, PTFE is exceptionally non-reactive and inert. This makes it resistant to virtually all industrial chemicals, ensuring it will not swell, degrade, or break down when exposed to corrosive substances.

The Energizing Inner Core

While the FEP/PTFE shell provides chemical protection, it is relatively rigid and lacks the "memory" or elasticity of rubber.

To solve this, the shell encapsulates a separate core made of a standard elastomer, such as Silicone or Viton™. This inner core acts like a spring, providing the consistent outward force needed to maintain a tight, reliable seal against the hardware surfaces.

The Result: High-Performance Sealing

This combination delivers a seal that can withstand aggressive chemicals while simultaneously providing the mechanical performance required for dynamic equipment like pumps, valves, and mechanical seals. The elastomer core provides the force, and the fluoropolymer shell provides the protection.

Key Performance Characteristics in Chemical Processing

The unique construction of encapsulated O-rings gives them several properties that are critical for safety and reliability in chemical plants.

Unmatched Chemical Resistance

The primary benefit is the ability to handle a wide spectrum of aggressive chemicals without failing. This prevents leaks, protects equipment, and ensures the purity of the chemical process is not compromised by a degrading seal.

High Thermal Stability

Both FEP and PTFE can withstand severe temperatures, from cryogenic lows to highs exceeding 200°C (400°F). This makes them reliable for use in chemical reactors and systems involving heated gases or liquids.

Low Friction Surface

The low coefficient of friction, or "non-stick" nature, of the PTFE/FEP jacket is highly beneficial. In moving parts like valve stems, it reduces wear and tear, prevents stick-slip action, and lowers the torque needed for actuation.

Understanding the Trade-offs

While highly effective, encapsulated O-rings are not a universal solution. Objectivity requires acknowledging their limitations.

Reduced Elasticity

Compared to a standard rubber O-ring, the rigid outer jacket is less forgiving. It has a higher compression set, meaning it is less able to rebound to its original shape after being compressed for a long time.

Installation Sensitivity

The fluoropolymer jacket can be damaged if it is stretched more than a small amount during installation. Using improper tools or forcing it over sharp threads can create a split in the jacket, leading to immediate seal failure.

Higher Initial Cost

The complex, multi-material manufacturing process makes encapsulated O-rings more expensive upfront than a standard elastomeric seal. Their value is justified by reducing costly downtime and maintenance in critical or corrosive services.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your operational goals.

- If your primary focus is handling highly aggressive chemicals: Encapsulated O-rings are often the safest and most reliable choice to prevent seal degradation.

- If your primary focus is process purity: The inert nature of the FEP/PTFE shell ensures it will not leach contaminants into the process media.

- If your primary focus is reliability in high-temperature systems: Their exceptional thermal stability provides a dependable seal in applications with wide temperature fluctuations.

Ultimately, choosing an FEP or PTFE encapsulated O-ring is a strategic decision to ensure safety, reliability, and long-term performance in critical chemical applications.

Summary Table:

| Key Feature | Benefit for Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation |

| High Thermal Stability | Withstands temperatures from cryogenic to over 200°C (400°F) |

| Low Friction Surface | Reduces wear, prevents stick-slip, and lowers actuation torque |

| Dual-Material Design | Combines PTFE/FEP chemical resistance with elastomer core elasticity |

Need a reliable sealing solution for your chemical processing equipment?

KINTEK specializes in manufacturing high-performance PTFE and FEP components, including custom encapsulated O-rings. Our precision engineering ensures your seals withstand aggressive chemicals, high temperatures, and demanding operational conditions—protecting your equipment and ensuring process purity.

Whether you need prototypes or high-volume orders for semiconductor, medical, laboratory, or industrial applications, we deliver solutions tailored to your specific requirements.

Contact us today to discuss your sealing challenges and get a custom quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss