For machining Polytetrafluoroethylene (PTFE), the most recommended techniques involve active cooling to manage its extreme sensitivity to heat. The primary methods are pressurized air, spray mists, or non-aromatic, water-soluble CNC coolants. These are often used in conjunction with dry lubricants to reduce friction, though care must be taken to avoid over-lubrication.

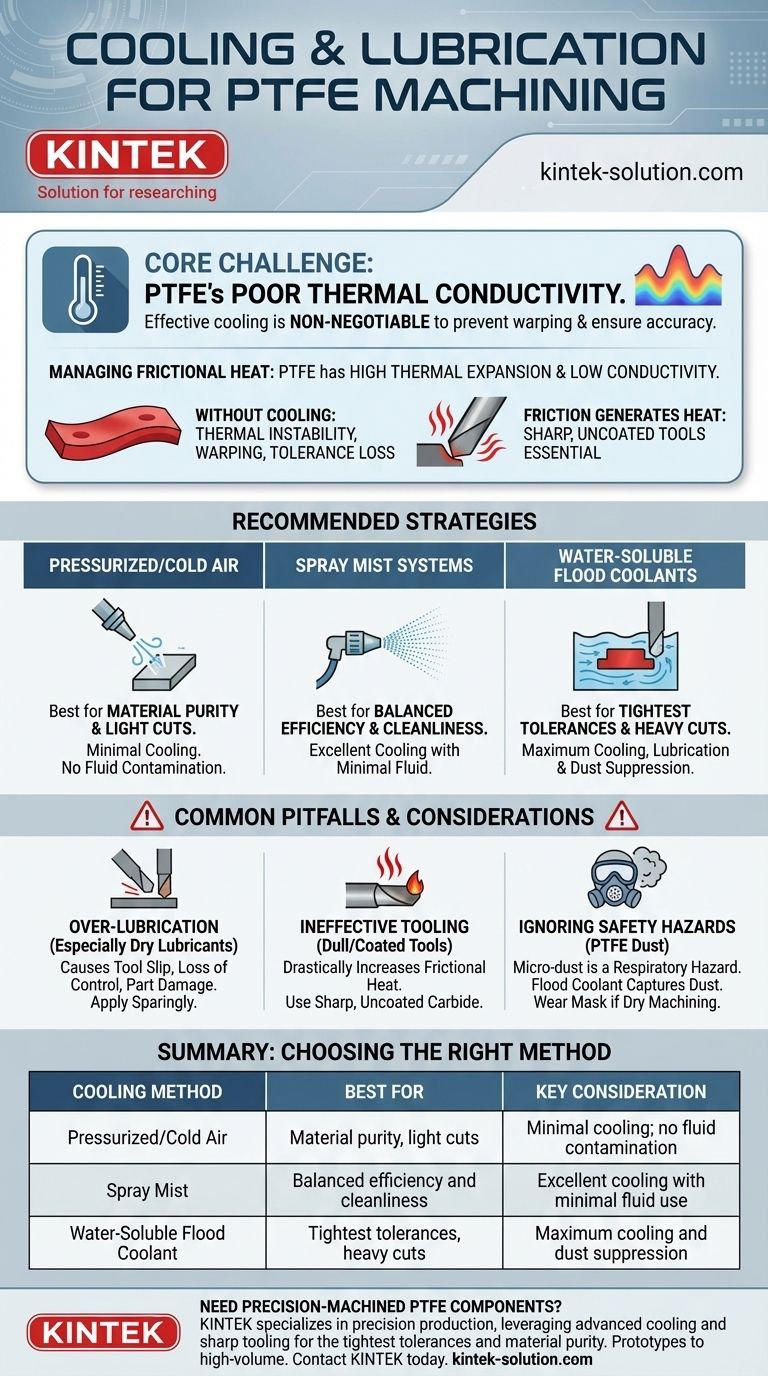

The central challenge in machining PTFE is not the material's hardness, but its poor thermal conductivity. Effective cooling is therefore non-negotiable, acting as the primary control for preventing thermal deformation, ensuring dimensional accuracy, and achieving a quality surface finish.

The Core Challenge: Managing Frictional Heat

PTFE's unique properties make it highly susceptible to problems caused by the heat generated during cutting. Understanding this is the key to successful machining.

Why Temperature Control is Critical

PTFE has a high rate of thermal expansion and very low thermal conductivity. This means that heat generated at the cutting edge doesn't dissipate quickly, causing the material to expand and warp locally.

Without active cooling, this thermal instability makes it nearly impossible to hold close tolerances and can easily ruin the part.

The Impact of Uncontrolled Friction

Friction between the cutting tool and the workpiece is the primary source of heat. Sharp, uncoated tools are essential because they reduce these frictional forces, minimizing heat generation from the start.

Proper cooling and lubrication directly address the heat that is inevitably produced, preventing it from deforming the material.

Recommended Cooling and Lubrication Strategies

Your choice of cooling method depends on the specific requirements of the job, such as tolerance, finish, and material purity.

Pressurized or Cold Air Systems

For operations where fluid contamination is a concern, a steady stream of cold, pressurized air is an effective choice. It helps to clear chips and provides moderate cooling.

This is a clean method but offers the least cooling power, making it best suited for lighter cuts and slower feed rates.

Spray Mist Systems

Spray mist systems offer a strong balance between cooling effectiveness and cleanliness. They apply a minimal amount of a water-soluble coolant directly to the cutting zone.

This approach is highly efficient, providing significant cooling with very little fluid, making it a popular all-around choice.

Water-Soluble Flood Coolants

For the most demanding applications with heavy cuts or extremely tight tolerances, a non-aromatic, water-soluble flood coolant is the most effective option. This method provides the maximum possible cooling and lubrication.

It also serves a critical safety function by suppressing the fine PTFE dust generated during machining, which can be hazardous if inhaled.

Common Pitfalls and Considerations

Success with PTFE requires avoiding a few common but critical mistakes.

The Danger of Over-Lubrication

While lubrication is beneficial for reducing friction, using too much—especially with dry lubricants—can cause the cutting tool to slip. This leads to a loss of control and can damage the part.

Apply lubricants sparingly and ensure the tool maintains positive engagement with the material.

Ineffective Tooling

Using dull or coated tools will drastically increase frictional heat, regardless of your cooling system. Always use exceptionally sharp, uncoated carbide-tipped tools designed for plastics.

This proactive step reduces the amount of heat your cooling system needs to manage in the first place.

Ignoring Safety Hazards

The micro-dust produced when machining PTFE is a serious respiratory hazard. Machining under a flood coolant is the safest method, as it captures the dust.

If machining dry with air cooling, always wear an appropriate mask and work in a well-ventilated area.

Making the Right Choice for Your Goal

Select your cooling and lubrication strategy based on the primary outcome you need to achieve for the finished part.

- If your primary focus is achieving the tightest tolerances: Use a water-soluble flood coolant for maximum thermal control and stability.

- If your primary focus is maintaining absolute material purity: Use a pressurized cold air system to avoid any potential fluid contamination.

- If your primary focus is a balance of cutting efficiency and cleanliness: A spray mist system provides an excellent and versatile solution.

By actively managing heat as the central variable, you can machine PTFE with predictable precision and confidence.

Summary Table:

| Cooling Method | Best For | Key Consideration |

|---|---|---|

| Pressurized/Cold Air | Material purity, light cuts | Minimal cooling; no fluid contamination |

| Spray Mist | Balanced efficiency and cleanliness | Excellent cooling with minimal fluid use |

| Water-Soluble Flood Coolant | Tightest tolerances, heavy cuts | Maximum cooling and dust suppression |

Need Precision-Machined PTFE Components?

Machining PTFE to exact specifications requires expertise in managing its unique thermal properties. At KINTEK, we specialize in the precision production of PTFE components—from custom seals and liners to complex labware.

We leverage advanced cooling techniques and sharp, uncoated tooling to ensure every part meets your tightest tolerances and highest standards for material purity. Whether you require prototypes or high-volume orders for the semiconductor, medical, or industrial sectors, we deliver reliable performance.

Let us put our expertise to work for you. Contact KINTEB today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments