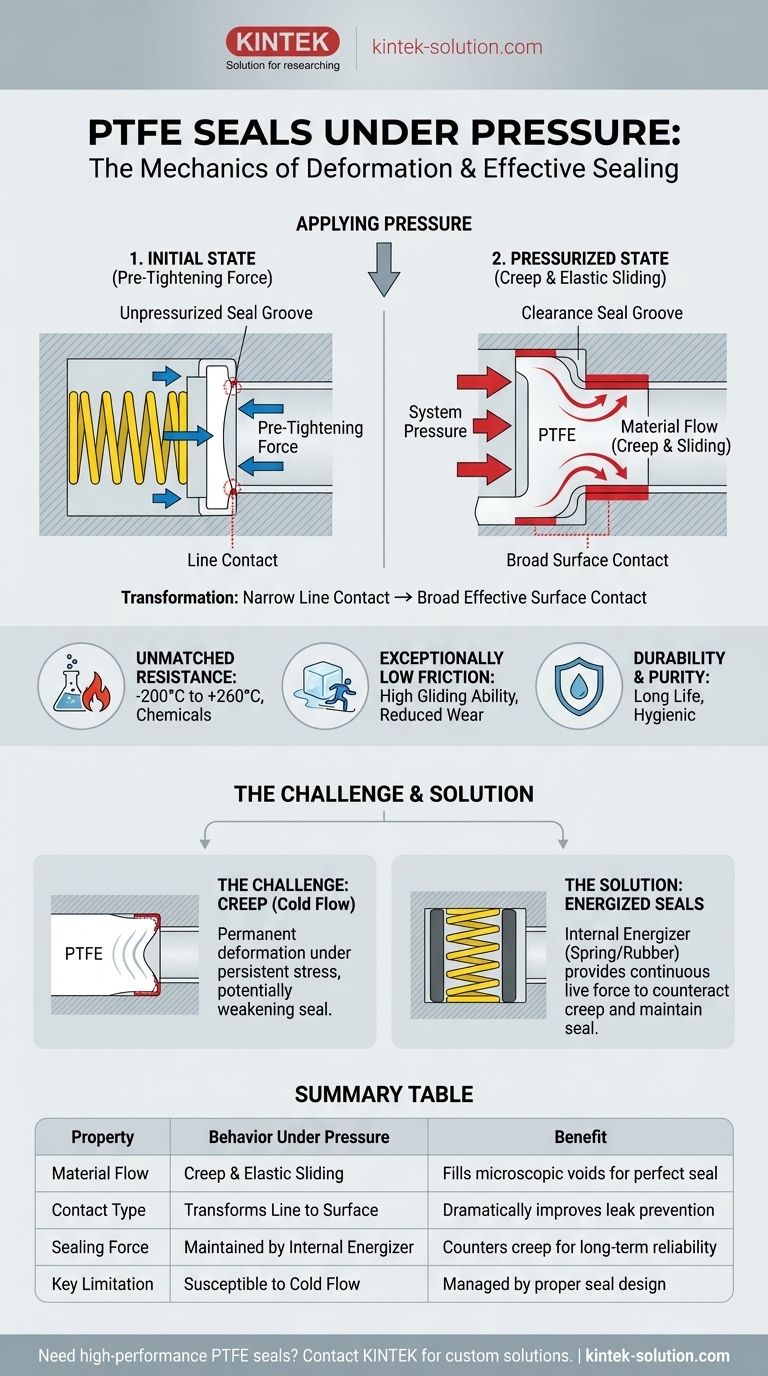

When pressure is applied, the PTFE material in a sealing ring intentionally deforms. It exhibits a behavior known as creep and elastic sliding, causing it to flow toward the sides of the seal groove. This movement transforms the seal's contact from a narrow line into a broad, effective surface area against the mating components.

The deformation of PTFE under pressure is not a failure but a core design principle. This controlled flow creates a highly effective surface seal, but it relies on an internal energizer (like a spring or rubber core) to counteract PTFE's natural tendency to creep and maintain a consistent sealing force.

The Mechanics of a PTFE Seal Under Pressure

To understand what happens when a system is pressurized, we must first look at the seal in its initial, unpressurized state. The design of a PTFE seal anticipates and leverages the material's unique properties.

The Initial State: Pre-Tightening Force

Before any system pressure is applied, an internal energizer, typically a metal spring or a bonded rubber core, is already at work.

This component exerts a constant outward force on the PTFE jacket. This creates an initial "pre-tightening" stress, ensuring the PTFE lips are already in close contact with the sealing surfaces.

Applying Pressure: Creep and Elastic Sliding

When system pressure is introduced, it acts on the seal assembly. The pressure forces the relatively soft PTFE material to move.

This movement is a combination of elastic sliding and creep (also called cold flow). The PTFE is pushed outward, away from the pressure source and towards the clearance gaps on either side of the groove.

The Result: From Line to Surface Contact

This controlled flow is the key to the seal's effectiveness. The initial seal is a very narrow line contact created by the energizer.

As the PTFE deforms under pressure, it spreads out to fill the microscopic voids in the hardware, contacting the groove walls firmly. This transforms the seal into a much wider and more robust surface contact, dramatically improving its ability to prevent leaks.

Why PTFE is a Premier Sealing Material

Despite its tendency to creep, PTFE is chosen for demanding applications because of a powerful combination of inherent properties that few other materials can match.

Unmatched Chemical and Thermal Resistance

PTFE is virtually inert to most aggressive chemicals, acids, and solvents.

It also operates reliably across an extreme temperature range, typically from -200°C to +260°C (-328°F to +500°F), making it suitable for cryogenic and high-heat applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This "high gliding ability" is critical in dynamic seals where parts are moving against each other, as it reduces wear, heat generation, and the energy required for operation.

Durability and Purity

The material is highly resistant to water, moisture, and corrosion, contributing to its long service life. Its non-stick, hygienic properties also make it a preferred choice in food, beverage, and medical applications.

Understanding the Trade-offs: The Challenge of Creep

The single most significant disadvantage of PTFE is its susceptibility to creep. Understanding and managing this property is the difference between a successful and a failed seal design.

What is Creep (or Cold Flow)?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For PTFE, this means that if left under constant compression without a restoring force, it will slowly flow and lose its original shape, potentially weakening the seal over time.

The Engineering Solution: Energized Seals

Designers overcome the challenge of creep by never relying on PTFE alone to provide the sealing force.

The internal spring or rubber energizer acts as the memory and resilience of the seal. It provides a continuous live force, pushing the PTFE jacket against the sealing surfaces and compensating for any material creep or wear that occurs over the seal's lifetime.

Making the Right Choice for Your Application

The decision to use a PTFE seal hinges on whether its benefits outweigh the design considerations required to manage its properties.

- If your primary focus is dynamic, low-friction performance: Energized PTFE seals are a leading choice due to their exceptional gliding ability and reduced wear.

- If your application involves aggressive chemicals or extreme temperatures: PTFE's inherent material resistance makes it one of the few viable options.

- If you need a seal for a high-pressure static application: An energized PTFE design is necessary to counteract cold flow and maintain a long-term, reliable seal.

Ultimately, understanding that PTFE's movement under pressure is a deliberate feature, not a flaw, is the key to engineering a robust and durable sealing system.

Summary Table:

| Property | Behavior Under Pressure | Benefit |

|---|---|---|

| Material Flow | Creep & Elastic Sliding | Fills microscopic voids for a perfect seal |

| Contact Type | Transforms from Line to Surface Contact | Dramatically improves leak prevention |

| Sealing Force | Maintained by Internal Energizer | Counters creep for long-term reliability |

| Key Limitation | Susceptible to Cold Flow | Managed by proper seal design (energizer) |

Need a high-performance PTFE seal for demanding conditions?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that leverages PTFE's advantages while expertly managing its properties for maximum durability and performance.

Contact KINTEK today to discuss your specific application requirements and get a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE an ideal material for bellows applications? Achieve Superior Sealing & Flexibility

- Why are PTFE seals preferred in press machinery in the pharmaceutical industry? Ensuring Purity and Performance

- What are the key properties of PTFE that make it suitable for sealing technology? Unlock Superior Performance in Extreme Conditions

- How do PTFE expansion bellows handle thermal expansion in piping systems? Prevent Stress and Failure

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What factors affect PTFE seal performance? Optimize Your System for Reliability & Longevity

- Why are PTFE rods suitable for medical applications? Unmatched Safety and Sterilization Performance

- How do expanded PTFE gaskets compare to rubber or plastic seals in terms of lifespan? Last Up to 7x Longer