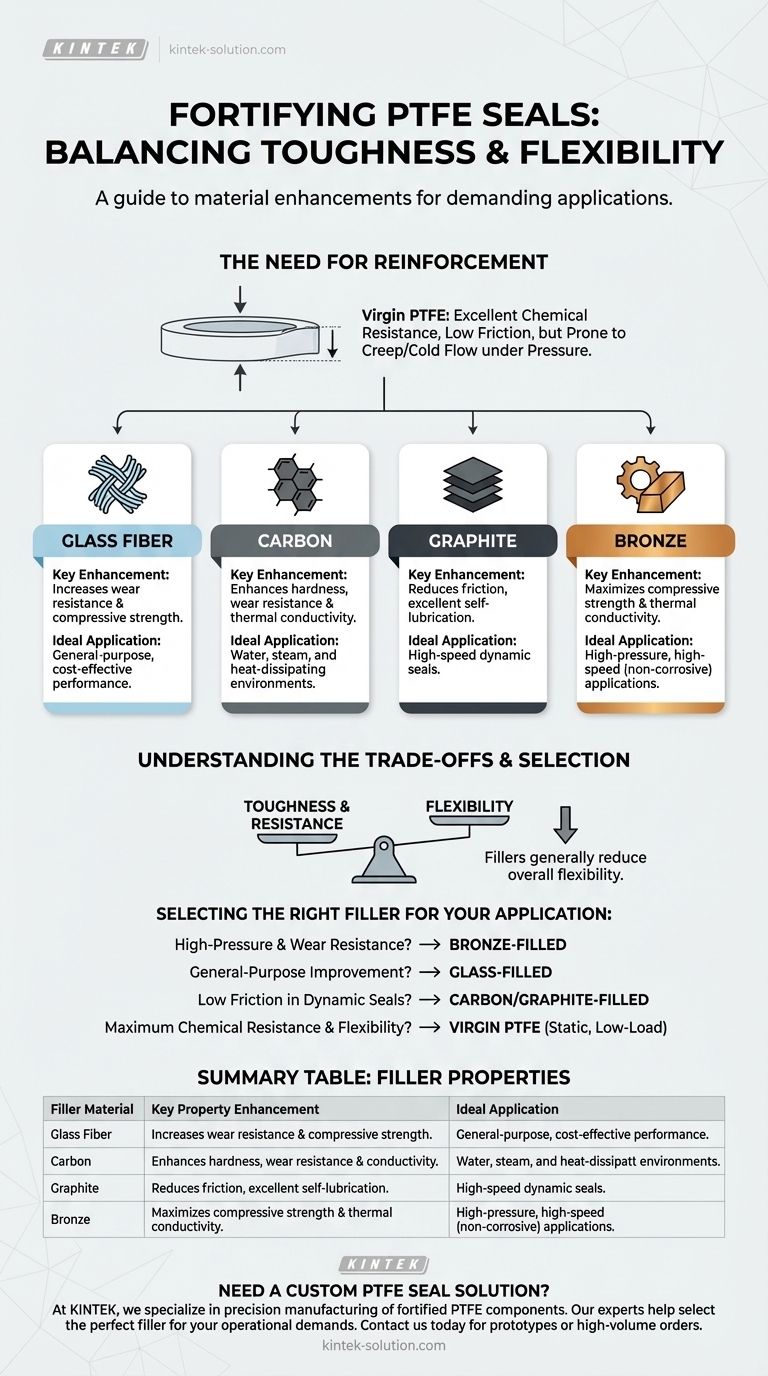

To fortify PTFE seals for demanding applications, engineers typically use fillers such as short glass fiber, bronze, carbon, and graphite. These additives are blended into the base PTFE material to enhance specific mechanical properties like wear resistance and compressive strength while retaining a functional level of flexibility.

While pure PTFE is known for its excellent chemical resistance and low-friction surface, it is mechanically weak and prone to deforming under load. Fillers are essential for tuning the material's properties to prevent failure in specific operational environments.

The Baseline: Understanding Virgin PTFE

Inherent Flexibility

Polytetrafluoroethylene (PTFE) possesses a unique molecular structure that allows it to remain flexible and pliable, even at extremely low temperatures. This makes it an excellent base material for sealing applications where it will not become brittle or crack.

The Need for Reinforcement

The primary weakness of pure, or virgin, PTFE is its tendency to deform under sustained pressure, a phenomenon known as creep or cold flow. This deformation can lead to seal failure. Fillers are added to counteract this tendency and improve other mechanical characteristics.

A Closer Look at Common PTFE Fillers

Each filler imparts a unique set of properties to the final seal material. The choice depends entirely on the specific demands of the application.

Glass Fiber

Glass fiber is one of the most common fillers used in PTFE. It significantly increases wear resistance and compressive strength, making the seal more durable under load. It offers a good all-around performance boost and is relatively cost-effective.

Carbon

Adding carbon to PTFE enhances its compressive strength, hardness, and wear resistance. Carbon-filled PTFE has excellent performance in water and steam applications and possesses good thermal conductivity, helping to dissipate heat from the sealing surface.

Graphite

Graphite is primarily used as a lubricant to reduce the coefficient of friction. It is often combined with other fillers, such as carbon, to create a compound that is both strong and self-lubricating, making it ideal for high-speed dynamic applications.

Bronze

For high-pressure and high-speed applications, bronze is the preferred filler. It provides the highest increase in compressive strength and thermal conductivity of all common fillers, but it has poor resistance to acids and other corrosive chemicals.

Understanding the Trade-offs

Adding fillers is always a matter of balancing competing properties. Improving one characteristic often comes at the expense of another.

The Balance of Properties

No single filler is universally superior. The goal is to select a compound that provides the necessary enhancements without introducing a new point of failure for your specific environment.

Impact on Flexibility

While fillers add toughness and resistance to deformation, they generally reduce the overall flexibility of the base PTFE. The engineering goal is to add just enough filler to achieve the required mechanical strength while maintaining sufficient pliability for the seal to function correctly.

Chemical Compatibility

It is critical to remember that the filler material may not share the same exceptional chemical resistance as pure PTFE. For instance, a bronze-filled seal would be unsuitable for use with strong acids, even though the PTFE itself would be unaffected.

Selecting the Right Filler for Your Application

Choose a material based on the most significant challenge your seal will face.

- If your primary focus is high-pressure and wear resistance: Bronze-filled PTFE is the optimal choice for its excellent compressive strength and thermal conductivity.

- If your primary focus is general-purpose improvement: Glass-filled PTFE provides a well-balanced profile of enhanced wear and strength for a wide range of applications.

- If your primary focus is low friction in dynamic seals: A carbon/graphite-filled compound offers superior self-lubricating properties for dry-running or high-speed conditions.

- If your primary focus is maximum chemical resistance and flexibility: Virgin (unfilled) PTFE remains the best option, especially in static, low-load environments.

By matching the filler to your operational demands, you can engineer a PTFE seal that delivers reliable, long-term performance.

Summary Table:

| Filler Material | Key Property Enhancement | Ideal Application |

|---|---|---|

| Glass Fiber | Increases wear resistance & compressive strength | General-purpose, cost-effective performance |

| Carbon | Enhances hardness, wear resistance & thermal conductivity | Water, steam, and heat-dissipating environments |

| Graphite | Reduces friction, excellent self-lubrication | High-speed dynamic seals |

| Bronze | Maximizes compressive strength & thermal conductivity | High-pressure, high-speed applications (non-corrosive) |

Need a custom PTFE seal solution tailored to your specific operational demands? At KINTEK, we specialize in precision manufacturing of PTFE components, including custom-fortified seals for the semiconductor, medical, laboratory, and industrial sectors. Our experts will help you select the perfect filler material—from glass and carbon to graphite and bronze—to balance toughness, flexibility, and chemical resistance for your unique application. Whether you require prototypes or high-volume orders, we deliver reliable performance. Contact us today to discuss your project and get a quote!

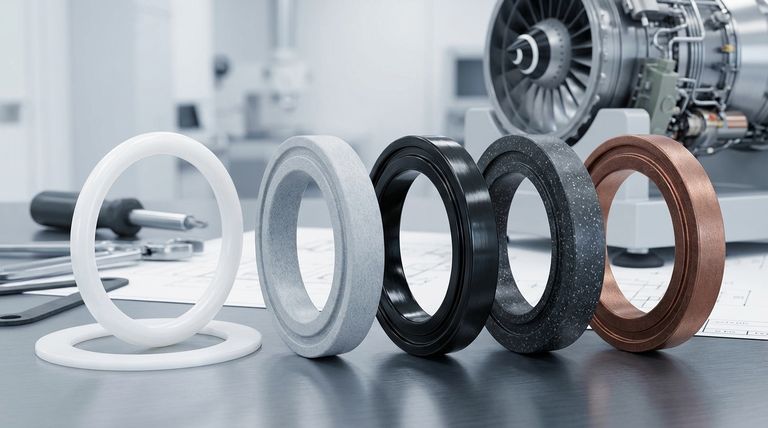

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency