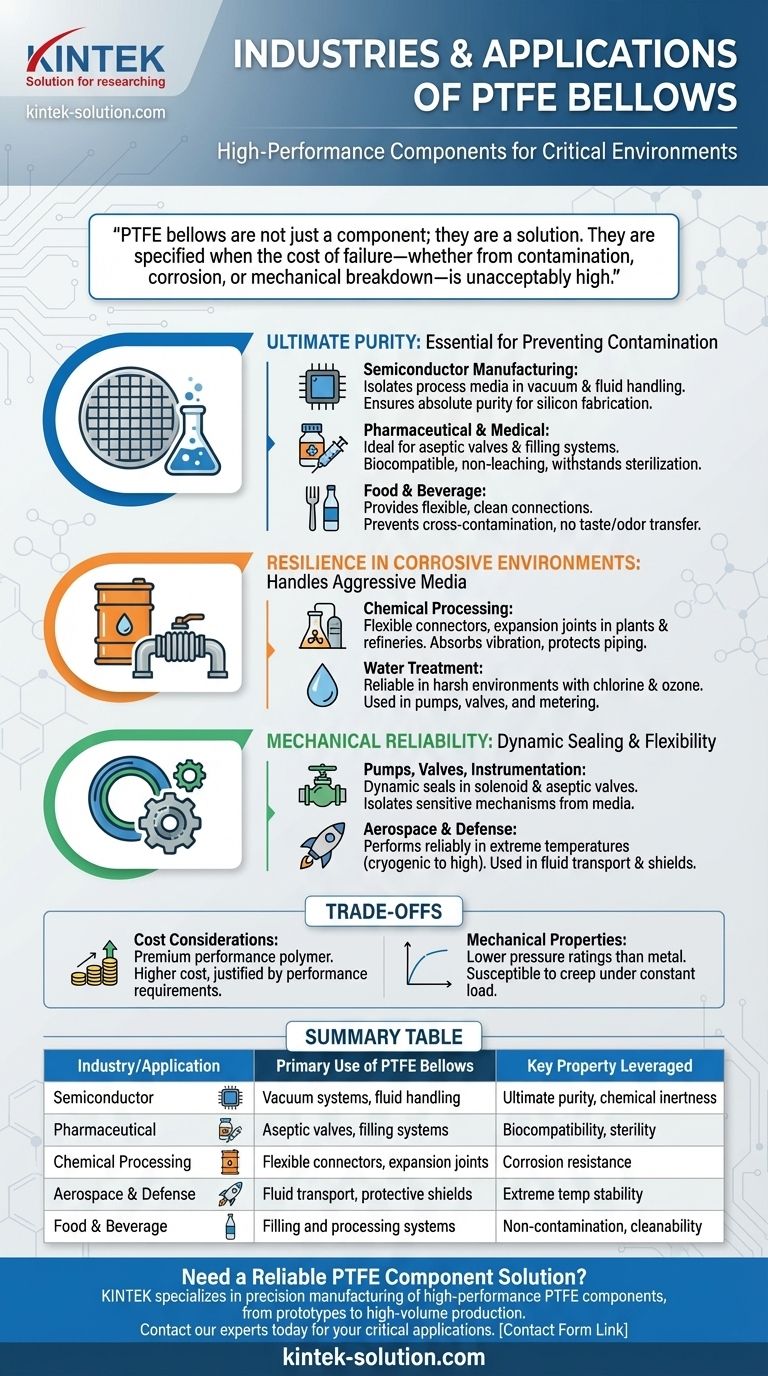

At their core, PTFE bellows are indispensable components in industries where performance cannot be compromised. They are most commonly used in semiconductor manufacturing, chemical processing, pharmaceutical and medical applications, and aerospace due to their unique combination of chemical inertness, high purity, and reliability in extreme environments.

PTFE bellows are not just a component; they are a solution. They are specified when the cost of failure—whether from contamination, corrosion, or mechanical breakdown—is unacceptably high.

The Demand for Ultimate Purity

The primary driver for using PTFE is its nearly total chemical inertness and non-leaching properties. This makes it essential for applications where even microscopic contamination can be catastrophic.

Semiconductor Manufacturing

In semiconductor fabrication, process purity is paramount. Any foreign particle or chemical leachant can ruin an entire batch of silicon wafers, costing millions.

PTFE bellows are used in vacuum systems and fluid handling equipment to isolate process media, ensuring absolute purity and chemical compatibility with the aggressive substances used in etching and cleaning.

Pharmaceutical and Medical

Sterility and biocompatibility are non-negotiable in medical devices and pharmaceutical production. PTFE is an ideal material because it does not react with biological fluids and can withstand stringent sterilization processes.

They are frequently found in aseptic valves, filling systems, and other equipment where preventing cross-contamination and ensuring product integrity is critical.

Food and Beverage

Similar to pharmaceuticals, the food and beverage industry requires components that do not impart any taste, odor, or contaminants into the product.

PTFE bellows serve in filling and processing systems to provide flexible, clean connections that prevent cross-contamination between batches and are easy to clean.

Resilience in Corrosive Environments

PTFE's ability to withstand nearly all industrial chemicals and solvents makes it the material of choice for containing and transporting aggressive media that would destroy metals and other plastics.

Chemical Processing

Chemical plants and oil refineries handle highly corrosive acids, bases, and solvents. PTFE bellows are used as flexible connectors, expansion joints in piping, and pulse dampeners.

Their function is to absorb vibration and thermal expansion while protecting the integrity of the piping system from chemical attack, preventing dangerous leaks and costly downtime.

Water Treatment and Pollution Control

Municipal and industrial water treatment facilities often use harsh chemicals like chlorine and ozone. PTFE components provide long-term reliability in these harsh environments.

They are used in pumps, valves, and metering devices where resistance to corrosion is essential for operational longevity.

Mechanical Reliability in Dynamic Systems

Beyond chemical properties, PTFE bellows provide reliable flexibility, vibration isolation, and sealing in complex mechanical assemblies.

Pumps, Valves, and Instrumentation

PTFE bellows are a core component in many types of valves (solenoid, aseptic) and pumps, where they act as a dynamic seal to shield sterile areas or isolate sensitive internal mechanisms from the process media.

In precision instruments, they isolate sensors from vibration or provide a flexible, hermetic seal, ensuring measurement accuracy and protecting delicate components.

Aerospace and Defense

In aerospace applications, components must perform reliably across extreme temperatures and pressures. PTFE maintains its properties from cryogenic levels up to high temperatures.

Its stability and durability make it suitable for fluid transport systems and as protective shields in demanding mechanical environments.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is not a universal solution. Understanding its limitations is key to proper application.

Cost Considerations

PTFE is a premium performance polymer, and machined bellows are a specialized product. They are significantly more expensive than components made from elastomers or standard plastics. Their use is justified when the performance requirements outweigh the initial cost.

Mechanical Properties

Compared to metal bellows, PTFE has lower pressure ratings and is susceptible to creep, or "cold flow," under a constant load. Design considerations must account for its lower tensile strength and potential for deformation over time, especially at elevated temperatures.

Making the Right Choice for Your Application

Selecting a PTFE bellow depends entirely on the primary problem you are trying to solve.

- If your primary focus is process purity: PTFE is the benchmark for applications in semiconductor, pharmaceutical, or high-purity analytics where contamination is not an option.

- If your primary focus is corrosion resistance: PTFE is the definitive choice for handling aggressive chemicals that would rapidly degrade most other materials.

- If your primary focus is a flexible seal in a dynamic system: PTFE offers an excellent combination of flexibility, durability, and chemical inertness for valves, pumps, and instrumentation.

Ultimately, specifying a PTFE bellow is a decision to prioritize reliability and purity above all else.

Summary Table:

| Industry/Application | Primary Use of PTFE Bellows | Key Property Leveraged |

|---|---|---|

| Semiconductor Manufacturing | Vacuum systems, fluid handling | Ultimate purity, chemical inertness |

| Pharmaceutical & Medical | Aseptic valves, filling systems | Biocompatibility, sterility |

| Chemical Processing | Flexible connectors, expansion joints | Corrosion resistance |

| Aerospace & Defense | Fluid transport systems, protective shields | Extreme temperature stability |

| Food & Beverage | Filling and processing systems | Non-contamination, cleanability |

Need a Reliable PTFE Component Solution?

When your application demands uncompromising purity, extreme chemical resistance, or reliable performance in dynamic systems, the cost of component failure is too high to risk.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bellows, seals, liners, and labware. We serve the semiconductor, medical, laboratory, industrial, and other specialized industries where quality is non-negotiable.

We partner with you from prototype development to high-volume production, ensuring your components meet the exact specifications required for your critical applications.

Let's discuss your project requirements. Contact our experts today to find the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the operational benefits of PTFE Lip Seals? Unlock Reliability in Extreme Conditions

- What is the typical application of PTFE bellow mechanical seals in pumps? Sealing Corrosive Fluids

- How does the contact pattern of PTFE seals compare to elastomer seals? The Key to Low-Friction Performance

- How do PTFE slide bearings compare in load capacity to traditional bearings? Superior Support for High-Load, Low-Speed Applications

- Why is a properly functioning piston seal important? The Key to Cylinder Power and Reliability

- What are bearing grades of PTFE used for? Achieve High-Performance, Self-Lubricating Components

- What solutions exist for the cold flow problem in PTFE gaskets? Prevent Leaks with Advanced Materials & Installation

- What are the symptoms of wear and tear in PTFE butterfly valves? Identify Leaks & High Torque