In short, the operational benefits of PTFE lip seals are their ability to perform reliably in extreme conditions that cause conventional elastomeric seals to fail. They excel in applications involving high temperatures, high pressures, and high rotational speeds while offering near-universal chemical resistance and exceptionally low friction. This makes them a superior choice for demanding industrial machinery where seal failure leads to significant downtime.

The core value of a PTFE lip seal is not just as a component, but as a solution to a difficult engineering problem. They are specified when the operational environment—be it temperature, pressure, speed, or chemical exposure—is simply too harsh for standard sealing solutions.

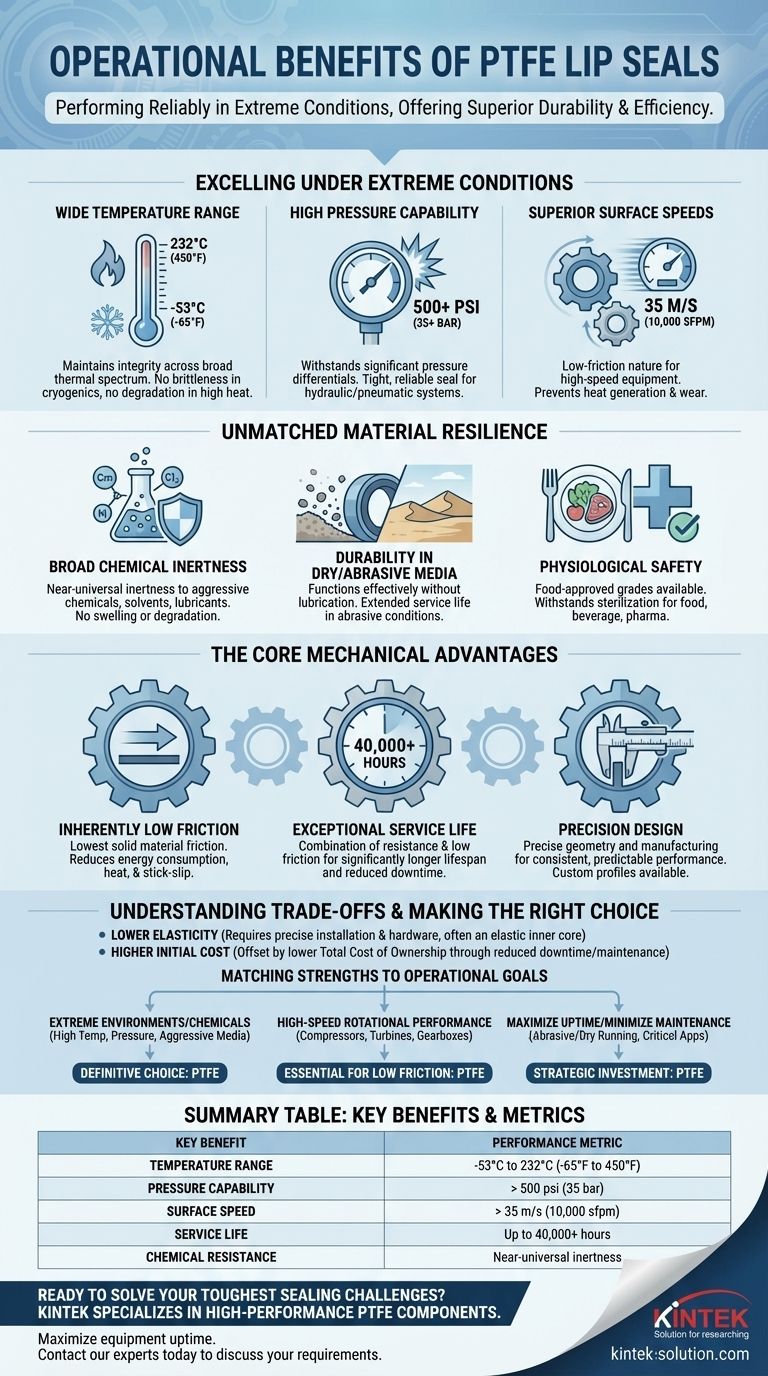

Excelling Under Extreme Operating Conditions

The primary driver for choosing a PTFE seal is its capacity to maintain integrity and sealing performance under conditions that would degrade or destroy other materials.

Wide Temperature Range

PTFE seals operate effectively across an exceptionally broad thermal spectrum. They can handle continuous service in temperatures ranging from -53°C to 232°C (-65°F to 450°F). This stability prevents the material from becoming brittle in cryogenic applications or degrading in high-heat environments.

High Pressure Capability

Unlike many conventional seals, PTFE lip seals are engineered to withstand significant pressure differentials. They can provide a tight, reliable seal in systems operating in excess of 500 psi (35 bar), making them suitable for high-pressure hydraulic and pneumatic equipment.

Superior Surface Speeds

The low-friction nature of PTFE allows these seals to be used in high-speed rotating equipment. They can accommodate surface speeds exceeding 35 m/s (or up to 10,000 sfpm), preventing the heat generation and subsequent wear that would quickly destroy a standard elastomeric seal.

Unmatched Material Resilience

The inherent properties of Polytetrafluoroethylene (PTFE) itself provide a set of advantages related to durability and compatibility.

Broad Chemical Inertness

PTFE is one of the most chemically inert materials used in engineering. This allows PTFE lip seals to be used with a vast range of aggressive chemicals, solvents, and lubricants without swelling, degrading, or failing.

Durability in Dry or Abrasive Media

A key operational benefit is the ability of PTFE seals to function effectively in dry-running or abrasive media conditions. Where a lubricated elastomer seal would fail from friction and wear, a PTFE seal can provide an extended service life.

Physiological Safety

Certain grades of PTFE are food-approved and physiologically inert. This, combined with their ability to withstand sterilization and disinfection processes, makes them ideal for applications in the food, beverage, and pharmaceutical industries.

The Core Mechanical Advantages

Beyond simple resilience, the mechanical design and properties of PTFE seals deliver tangible benefits in terms of efficiency and longevity.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property reduces energy consumption, minimizes heat buildup at the sealing point, and prevents the "stick-slip" effect common with other seals, ensuring smoother operation.

Exceptional Service Life

The combination of wear resistance, chemical stability, and low friction results in a significantly longer operational lifespan. In some well-designed applications, PTFE seals have been shown to provide over 40,000 hours of maintenance-free service, drastically reducing equipment downtime.

Precision Design

The reliability of a PTFE seal comes from the precise geometry of the seal lip, the steel casing, and a meticulous manufacturing process. This allows for a more mathematical and predictable approach to sealing, ensuring consistent performance. Custom profiles can also be designed for unique or challenging applications.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal replacement for all other seal types. Understanding their characteristics is key to successful implementation.

Lower Elasticity Compared to Rubber

PTFE is a much more rigid material than common elastomers like nitrile or viton. It does not have the same "bounce-back" memory, meaning it is less forgiving of shaft imperfections or significant runout. The design often incorporates an elastic inner core to help compensate for this.

The Importance of Precision

Because of their lower elasticity, the performance of PTFE seals is highly dependent on precise installation and the condition of the hardware. A proper fit between the seal's steel casing and the housing bore (e.g., meeting DIN 3760 interference standards) is critical for a reliable static seal.

Evaluating Total Cost of Ownership

PTFE seals typically have a higher initial purchase price than standard elastomeric seals. However, their value is realized by considering the total cost of ownership. The reduction in downtime, maintenance, and lost production in a critical application often far outweighs the higher upfront component cost.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the component's strengths to your primary operational goal.

- If your primary focus is reliability in extreme environments: PTFE is the definitive choice for applications with high temperatures, aggressive chemicals, or high pressures where elastomers would fail.

- If your primary focus is high-speed rotational performance: The low-friction characteristics of PTFE are essential to prevent heat buildup and premature wear in equipment like compressors, turbines, and high-speed gearboxes.

- If your primary focus is maximizing uptime and minimizing maintenance: The exceptional longevity and durability of PTFE seals in abrasive or dry-running conditions make them a strategic investment to extend service intervals.

- If your primary focus is a standard, low-demand application: A conventional elastomeric seal may provide sufficient performance at a lower initial cost.

Ultimately, choosing a PTFE lip seal is a decision to engineer for reliability in the most demanding circumstances.

Summary Table:

| Key Benefit | Performance Metric |

|---|---|

| Temperature Range | -53°C to 232°C (-65°F to 450°F) |

| Pressure Capability | > 500 psi (35 bar) |

| Surface Speed | > 35 m/s (10,000 sfpm) |

| Service Life | Up to 40,000+ hours |

| Chemical Resistance | Near-universal inertness |

Ready to solve your toughest sealing challenges?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution engineered for reliability and longevity in your specific extreme environment.

Maximize your equipment uptime and performance. Contact our experts today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries