At its core, a Teflon check valve serves a critical role in industrial operations by preventing reverse flow in piping systems that handle aggressive or high-purity media. Its impact is most significant in applications where chemical corrosion or fluid contamination would lead to equipment failure, production downtime, and serious safety hazards. This specialized function directly protects system integrity and, by extension, operational profitability.

The true impact of a Teflon check valve isn't just its ability to stop backflow; it's the material's extreme chemical inertness. This property ensures the valve protects the system from the fluid and, just as importantly, protects the fluid from contamination by the valve itself.

The Core Function: Preventing Contamination and Damage

A check valve is fundamentally a one-way gate for fluid. It allows flow in the desired direction while automatically closing to prevent any backflow caused by changes in system pressure.

Why Use Teflon (PTFE)?

The defining characteristic of Teflon, or Polytetrafluoroethylene (PTFE), is its near-universal chemical inertness. It resists degradation from almost all industrial chemicals, acids, and solvents.

This makes it the material of choice when standard metal or plastic valves would corrode and fail. The parts of the valve that come into contact with the fluid (the "wetted parts") are constructed from or lined with Teflon.

The Impact on System Integrity

When a valve corrodes, it not only fails to perform its function but also leaches metallic ions or other contaminants into the process fluid.

A Teflon check valve eliminates this risk. It creates a completely inert barrier, ensuring the purity of the fluid remains unchanged and downstream equipment is protected from corrosive attack.

How Teflon Check Valves Drive Profitability

The choice of a valve material may seem like a minor detail, but it has a direct and measurable effect on an operation's bottom line. This is achieved through reliability and quality assurance.

Maximizing Uptime by Preventing Failure

In systems handling chemicals like sulfuric acid, bleach, or solvents, a standard metal valve can fail in weeks or months. Each failure requires a system shutdown for replacement.

By resisting chemical attack, Teflon valves operate reliably for far longer, drastically reducing unplanned downtime and associated production losses.

Ensuring Product Purity and Quality

In industries like pharmaceuticals, semiconductors, and food and beverage, even trace amounts of contamination can ruin an entire batch of product.

The non-leaching nature of Teflon is non-negotiable in these environments. It guarantees that the final product meets stringent quality and safety standards, preventing costly recalls or batch rejection.

Reducing Total Cost of Ownership

While Teflon valves have a higher initial purchase price, they often have a lower total cost of ownership (TCO) in the correct application.

This is because the cost of repeated valve replacements, labor, and lost production due to failure far outweighs the initial premium for a chemically resistant valve.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Objectivity requires acknowledging where Teflon check valves are not the ideal choice.

Temperature and Pressure Constraints

Teflon's primary weakness is its performance under high temperature and pressure. It has a significantly lower operating temperature limit (typically around 200°C / 400°F) compared to stainless steel or other metal alloys.

As temperature increases, its pressure rating and mechanical strength decrease, making it unsuitable for high-energy steam or certain high-pressure hydraulic systems.

Potential for Creep and Deformation

PTFE is a relatively soft material that can be subject to "creep"—a slow, permanent deformation under sustained mechanical stress.

In high-pressure applications or improperly supported systems, this can eventually compromise the valve's sealing capability over its long-term service life.

The Critical Link to System Safety

Beyond profitability, the most important impact of proper valve selection is on personnel and environmental safety.

Preventing Hazardous Chemical Backflow

The primary safety function of any check valve is preventing backflow. When dealing with hazardous chemicals, this function becomes critical.

A failed valve could allow a concentrated acid to flow back into a water line or an incompatible chemical to mix with another, creating a dangerous reaction. The reliability of a Teflon valve in a corrosive environment is a direct safety control.

Mitigating Risks in High-Purity Systems

In biopharmaceutical or medical applications, contamination is not just a quality issue; it is a direct patient safety issue.

A Teflon check valve helps ensure that fluids used in these critical processes remain sterile and free from any foreign material that could be introduced by a degrading component.

Making the Right Choice for Your Operation

Choosing the right check valve requires you to match the material to the specific demands of your system.

- If your primary focus is handling highly corrosive chemicals: A Teflon check valve is essential for protecting equipment from corrosion, maximizing uptime, and ensuring safety.

- If your primary focus is maintaining absolute fluid purity: The non-leaching, inert properties of a Teflon wetted path are non-negotiable for industries like semiconductors or pharmaceuticals.

- If your primary focus is a high-temperature or high-pressure application with non-corrosive media: A robust metal alloy valve, such as one made from stainless steel or Inconel, is likely the more appropriate and reliable choice.

Ultimately, selecting a Teflon check valve is a strategic decision to invest in the long-term chemical compatibility and integrity of your most demanding fluid handling systems.

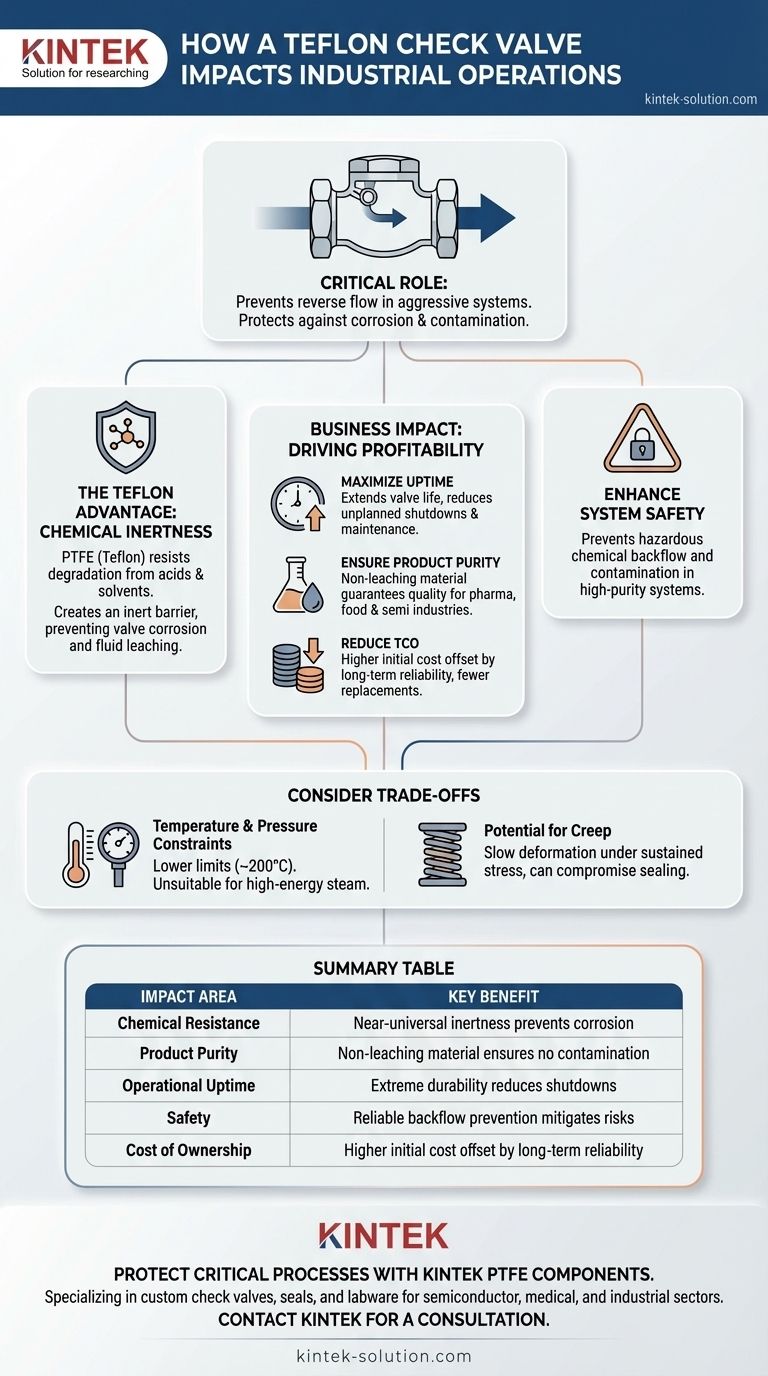

Summary Table:

| Impact Area | Key Benefit of Teflon Check Valve |

|---|---|

| Chemical Resistance | Near-universal inertness prevents corrosion from aggressive chemicals. |

| Product Purity | Non-leaching material ensures no contamination in high-purity processes. |

| Operational Uptime | Extreme durability reduces unplanned shutdowns and maintenance. |

| Safety | Reliable backflow prevention mitigates hazardous chemical risks. |

| Cost of Ownership | Higher initial cost is offset by long-term reliability and reduced failures. |

Protect your critical processes with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, pharmaceutical, or industrial sector, the chemical inertness and purity of Teflon are essential for your operations. KINTEK specializes in manufacturing high-quality PTFE components, including custom check valves, seals, liners, and labware.

We partner with you from prototype to high-volume production to deliver solutions that maximize uptime, ensure product quality, and enhance safety. Let's discuss how our custom fabrication expertise can solve your specific fluid handling challenges.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using Teflon bushings across different industries? Achieve Maintenance-Free Performance

- How does the company ensure quality in PTFE wear strips and bands? Achieve Consistent Performance & Dimensional Accuracy

- What are the advantages of using PTFE seals in fluid power applications? Solve Extreme Performance Challenges

- How does the low friction coefficient of PTFE coatings affect tightening torque? Achieve Accurate Clamping Force Safely

- What are the advantages of multi-axis CNC machines for PTFE machining? Achieve Superior Precision for Complex Parts

- How does the wide temperature range of PTFE gaskets benefit industrial applications? Achieve Reliable Sealing from -200°C to +260°C

- What are the key characteristics of PTFE gasket materials? Engineered for Extreme Chemical & Thermal Resistance

- How can PTFE's properties be enhanced? Boost Performance with Filled PTFE Composites