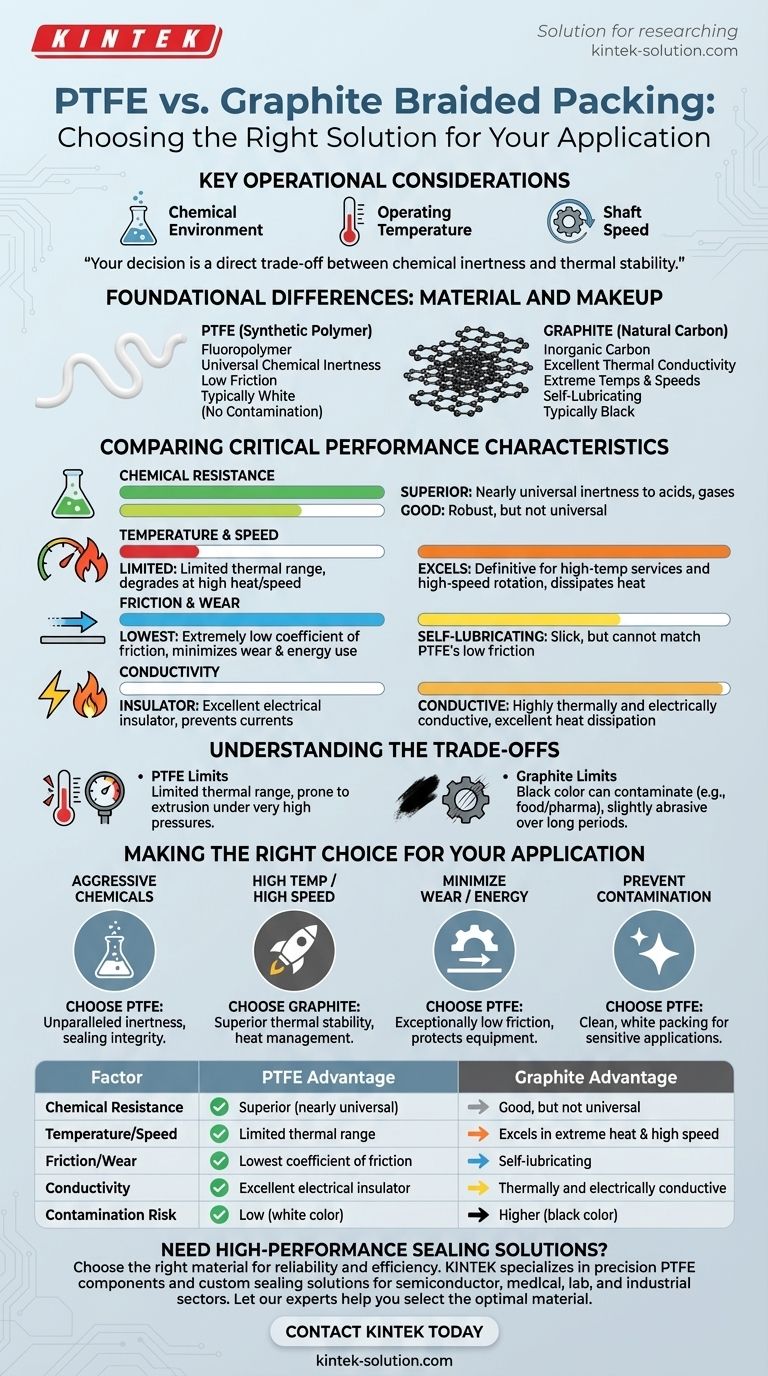

The choice between PTFE and graphite braided packing hinges on three primary operational factors: the chemical environment, the operating temperature, and the equipment's shaft speed. PTFE is a synthetic polymer prized for its exceptional chemical resistance and low friction, while graphite, a form of pure carbon, excels in high-temperature and high-speed applications.

Your decision is a direct trade-off between chemical inertness and thermal stability. PTFE offers superior protection in corrosive environments, whereas graphite provides unmatched reliability under extreme heat and high rotational speeds.

Foundational Differences: Material and Makeup

To make an informed choice, it's crucial to understand what these materials are at their core. Their fundamental composition dictates their performance characteristics.

Synthetic Polymer (PTFE)

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer. Its molecular structure is the source of its most valuable properties, including its near-universal chemical inertness and an extremely low coefficient of friction. It is typically white, preventing product contamination in sensitive applications.

Natural Carbon (Graphite)

Graphite is an inorganic, naturally occurring form of pure carbon. This composition gives it excellent thermal conductivity and the ability to withstand extreme temperatures far beyond the limits of synthetic polymers. It is self-lubricating and typically black.

Comparing Critical Performance Characteristics

The right choice becomes clear when you map the demands of your application to the distinct strengths of each material.

Chemical Resistance: The PTFE Advantage

For applications involving aggressive acids, gases, and corrosive chemicals, PTFE is the superior choice. It is resistant to nearly all industrial chemicals, with the rare exception of molten alkali metals. Graphite, while robust, does not offer the same level of near-universal inertness.

Temperature and Speed: Where Graphite Excels

Graphite's ability to dissipate heat makes it the definitive material for high-temperature services and high-speed rotating equipment. It maintains its integrity and lubricating properties where PTFE would quickly degrade. If your application involves extreme heat or fast-moving shafts, graphite is the standard.

Friction and Wear: A Clear Win for PTFE

PTFE has the lowest coefficient of friction of any solid material. This property translates directly to reduced drag on rotating shafts, minimizing wear and lowering energy consumption. While graphite is also self-lubricating, it cannot match PTFE's exceptionally slick surface.

Conductivity: A Key Differentiator

This is a critical, often overlooked factor. Graphite is highly conductive both thermally and electrically, which is essential for dissipating heat but can be a problem in applications requiring electrical isolation. PTFE is a strong insulator, making it ideal for preventing electrical currents from passing through the seal.

Understanding the Trade-offs

Neither material is universally perfect. Selecting the right one means accepting a specific set of limitations.

The Limits of PTFE: Temperature and Pressure

The primary weakness of PTFE is its limited thermal range. It cannot handle the extreme temperatures that graphite can. Additionally, while its tensile strength is higher (2,000 PSI vs. 650 PSI for graphite), it can be more prone to extrusion under very high pressures without proper reinforcement.

The Limits of Graphite: Purity and Abrasion

Graphite's black color can be a source of product contamination, making it unsuitable for industries like food processing or pharmaceuticals. While self-lubricating, it can be slightly more abrasive than PTFE over long periods, especially if the packing is not properly maintained.

Making the Right Choice for Your Application

Use your primary operational demand as your guide to select the optimal material for reliable, long-term sealing.

- If your primary focus is aggressive chemical resistance: Choose PTFE for its unparalleled inertness and sealing integrity in corrosive environments.

- If your primary focus is high temperature or high shaft speed: Choose graphite for its superior thermal stability and ability to manage heat effectively.

- If your primary focus is minimizing shaft wear and energy use: Choose PTFE for its exceptionally low coefficient of friction, which protects equipment and reduces drag.

- If your primary focus is preventing product contamination: Choose the clean, white PTFE packing, especially for food, beverage, or pharmaceutical applications.

Matching the material's core strengths to your operational demands is the key to achieving reliable, long-term sealing performance.

Summary Table:

| Factor | PTFE Advantage | Graphite Advantage |

|---|---|---|

| Chemical Resistance | Superior (nearly universal inertness) | Good, but not universal |

| Temperature/Speed | Limited thermal range | Excels in extreme heat & high speed |

| Friction/Wear | Lowest coefficient of friction | Self-lubricating |

| Conductivity | Excellent electrical insulator | Thermally and electrically conductive |

| Contamination Risk | Low (white color) | Higher (black color) |

Need High-Performance Sealing Solutions?

Choosing the right packing material is critical for your equipment's reliability and efficiency. KINTEK specializes in manufacturing precision PTFE components, including custom braided packings, seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a sealing solution perfectly matched to your specific chemical, temperature, and speed requirements.

Let our experts help you select the optimal material for long-term performance. Contact KINTEK today to discuss your application needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the compression and rebound characteristics of ePTFE gaskets? Master Sealing for Demanding Flanges

- Why are PTFE and PEEK suitable for backup rings? Ensure Seal Integrity in Extreme Conditions

- What are the benefits of using PTFE lined valves? Achieve Superior Reliability in Corrosive Applications

- What are the main advantages of PTFE mechanical seals? Superior Chemical & Temperature Resistance

- What standard surface finishes are available for PTFE balls? Tumbled vs. Machined for Optimal Performance

- How can PTFE be modified for different applications? Tailor Performance with Fillers and Processing

- What medical applications benefit from PTFE liners with high yield strength? Enhance Precision in Complex Procedures

- How is Teflon used in cookware? Leveraging Non-Stick Properties for Superior Cooking