Fillers fundamentally enhance the performance of PTFE O-rings by addressing the material's inherent weaknesses. Adding specific fillers like glass, graphite, or bronze creates a composite material that significantly improves mechanical strength, resistance to wear, and stability under heavy loads and high pressure. This reinforcement prevents the deformation and "creep" that virgin PTFE is susceptible to.

The core problem with standard PTFE is its softness and tendency to deform under pressure, a phenomenon known as creep. Fillers act as a reinforcing matrix within the PTFE, creating a stronger, more durable composite material tailored for specific demanding applications.

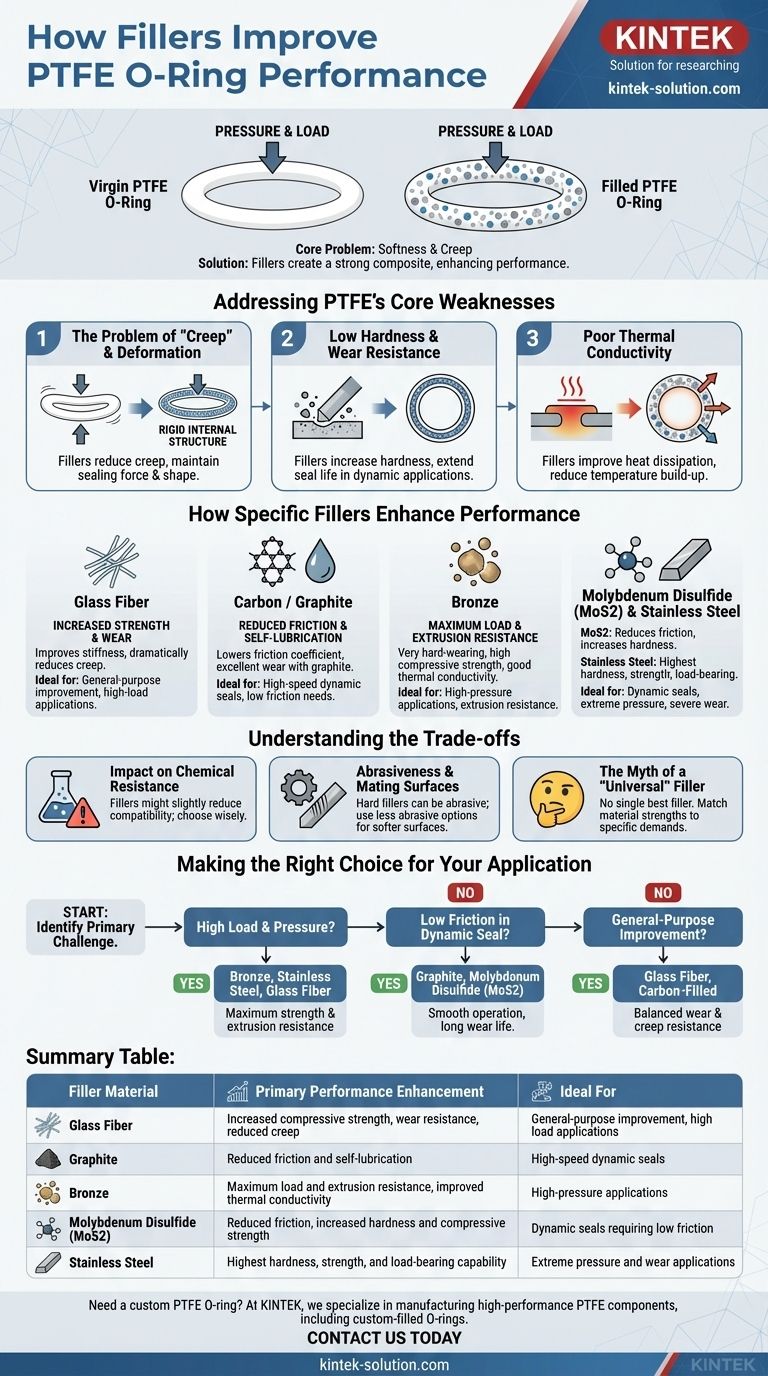

Addressing PTFE's Core Weaknesses

Polytetrafluoroethylene (PTFE) is renowned for its chemical inertness and low friction, but its mechanical properties are limited. Fillers are introduced to systematically overcome these limitations.

The Problem of "Creep" and Deformation

Virgin PTFE can slowly deform or "creep" over time when subjected to a constant load, especially at elevated temperatures. This leads to seal failure.

Fillers provide a rigid internal structure, drastically reducing creep and improving the O-ring's ability to maintain its shape and sealing force under sustained pressure.

Low Hardness and Wear Resistance

The soft, low-friction surface of standard PTFE is also prone to abrasion and wear in dynamic sealing applications.

Adding harder filler materials increases the surface hardness and overall wear resistance, extending the operational life of the seal significantly, particularly in applications involving frequent movement.

Poor Thermal Conductivity

PTFE is a poor conductor of heat, meaning friction-generated heat at the sealing interface can build up. This can accelerate wear and material degradation.

Many fillers, especially metallic or carbon-based ones, improve thermal conductivity. This allows them to dissipate heat away from the seal surface, reducing the interface temperature and prolonging the seal's life.

How Specific Fillers Enhance Performance

The choice of filler is not arbitrary; it is selected to target a specific performance enhancement required by the application.

For Increased Strength and Wear Resistance

Glass fibers are a common, general-purpose filler that dramatically improves compressive strength and wear resistance. They provide a significant boost in stiffness and reduce creep.

Carbon fillers also enhance compressive strength and load resistance. When combined with graphite, they offer excellent wear properties with low friction.

For Reduced Friction and Self-Lubrication

Graphite acts as a self-lubricating filler. It lowers the coefficient of friction and improves wear resistance, making it ideal for high-speed dynamic applications where friction needs to be minimized.

Molybdenum disulfide (MoS2) is another solid lubricant that reduces friction, often used in dynamic seals. It also increases the hardness and compressive strength of the PTFE material.

For Maximum Load and Extrusion Resistance

Bronze fillers provide excellent improvements in compressive strength and thermal conductivity. They create a very hard-wearing material suitable for high-pressure applications where resistance to extrusion is critical.

Stainless steel offers the highest level of hardness, strength, and load-bearing capability. It is specified for the most demanding applications where the seal must withstand extreme pressure and wear.

Understanding the Trade-offs

While fillers provide targeted benefits, they also introduce compromises that must be considered for proper material selection.

The Impact on Chemical Resistance

Virgin PTFE has nearly universal chemical resistance. Adding a filler material can slightly reduce this compatibility, as the filler itself may not be as inert as the PTFE. For instance, a bronze-filled seal would not be suitable for use with certain corrosive acids.

Abrasiveness and Mating Surfaces

Hard fillers like glass and bronze can be abrasive to softer mating surfaces, such as aluminum or plastic shafts. In such cases, a less abrasive filler like graphite or MoS2 is a better choice to prevent damage to the hardware.

The Myth of a "Universal" Filler

There is no single "best" filler for all situations. Each one optimizes a specific property, often at the expense of another. Choosing the right filled PTFE is about matching the material's strengths to the application's unique demands.

Making the Right Choice for Your Application

Selecting the correct filler requires a clear understanding of your primary operational challenge.

- If your primary focus is high load and pressure resistance: Choose a material filled with bronze, stainless steel, or glass fiber for maximum strength and extrusion resistance.

- If your primary focus is low friction in a dynamic seal: Select a graphite or molybdenum disulfide (MoS2) filled material to ensure smooth operation and long wear life.

- If your primary focus is general-purpose improvement over virgin PTFE: A glass fiber or carbon-filled compound offers a balanced enhancement of wear and creep resistance.

Ultimately, engineering the right seal means precisely matching the filler material to the specific challenge your application presents.

Summary Table:

| Filler Material | Primary Performance Enhancement | Ideal For |

|---|---|---|

| Glass Fiber | Increased compressive strength, wear resistance, and reduced creep | General-purpose improvement, high load applications |

| Graphite | Reduced friction and self-lubrication | High-speed dynamic seals |

| Bronze | Maximum load and extrusion resistance, improved thermal conductivity | High-pressure applications |

| Molybdenum Disulfide (MoS2) | Reduced friction, increased hardness and compressive strength | Dynamic seals requiring low friction |

| Stainless Steel | Highest hardness, strength, and load-bearing capability | Extreme pressure and wear applications |

Need a custom PTFE O-ring engineered for your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-filled O-rings for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact seal solution to overcome challenges like creep, wear, and high pressure.

Contact us today to discuss your requirements and let our experts help you select the optimal filler material for superior performance and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials