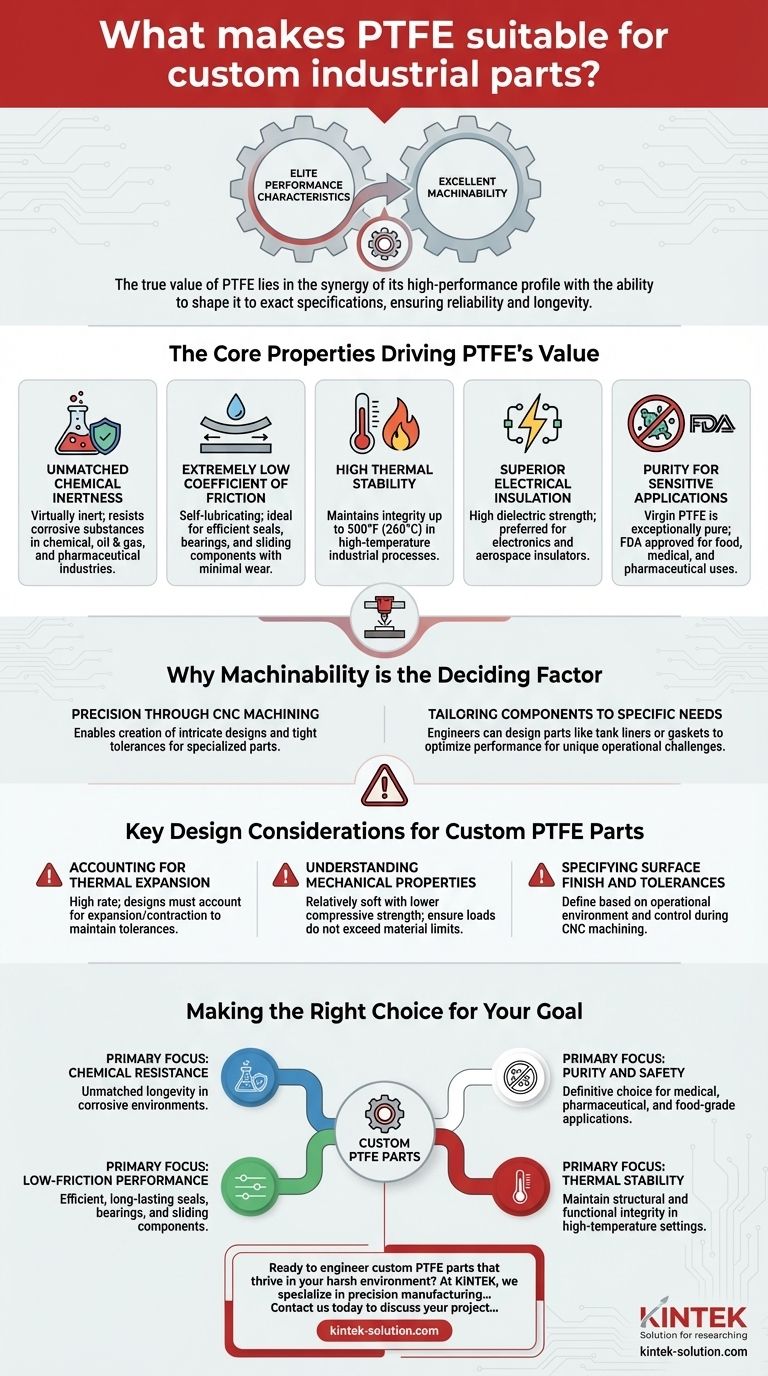

Ultimately, PTFE is an ideal material for custom industrial parts because it combines a set of elite performance characteristics with excellent machinability. Its inherent resistance to chemicals, heat, and friction allows it to thrive in harsh environments where other materials fail, while its ability to be precisely CNC machined enables the creation of complex, application-specific components.

The true value of PTFE for custom parts lies not in a single property, but in the synergy of its high-performance profile with the ability to shape it to exact specifications, ensuring reliability and longevity in the most demanding industrial applications.

The Core Properties Driving PTFE's Value

The suitability of Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, stems from a unique combination of intrinsic qualities. These properties make it a default choice for components that must perform reliably under extreme conditions.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with most chemicals. This makes it invaluable for parts used in chemical processing, oil and gas, and pharmaceutical industries where components are exposed to corrosive substances.

Extremely Low Coefficient of Friction

With one of the lowest friction coefficients of any solid material, PTFE is naturally "non-stick" and self-lubricating. This property is critical for creating custom bearings, seals, and sliding components that operate with high efficiency and minimal wear.

High Thermal Stability

PTFE parts maintain their integrity and performance at continuous service temperatures up to 500°F (260°C). This heat resistance allows them to be used in high-temperature industrial processes without degrading.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. This makes it a preferred material for custom insulators, connectors, and other components in the electronics and aerospace sectors.

Purity for Sensitive Applications

Virgin PTFE, which contains no recycled material or fillers, is exceptionally pure. This quality, combined with FDA approval for food contact, makes it the standard for parts used in medical, pharmaceutical, and food processing applications.

Why Machinability is the Deciding Factor

A material's inherent properties are only useful if it can be formed into the required shape. PTFE's excellent machinability is what unlocks its potential for custom industrial solutions.

Precision Through CNC Machining

PTFE can be machined with high precision using CNC (Computer Numerical Control) equipment. This process allows for the creation of intricate designs and the achievement of tight tolerances required for specialized parts like seals and linings.

Tailoring Components to Specific Needs

The ability to machine PTFE allows engineers to design parts that solve unique operational challenges. Custom components like chemical-resistant tank liners, food-grade cutting surfaces, or precision-engineered gaskets are fabricated to optimize performance for a specific environment.

Key Design Considerations for Custom PTFE Parts

While powerful, PTFE is not a universal solution. Designing effective custom parts requires a clear understanding of its mechanical behavior to avoid common pitfalls.

Accounting for Thermal Expansion

PTFE has a relatively high rate of thermal expansion. Designs must account for how the part will expand and contract with temperature fluctuations to maintain critical tolerances during operation.

Understanding Mechanical Properties

PTFE is a relatively soft material with lower compressive strength compared to metals. The design must ensure that the mechanical loads of the application do not exceed the material's limits, which could cause deformation.

Specifying Surface Finish and Tolerances

The operational environment dictates the necessary surface finish and dimensional tolerances. These variables must be clearly defined during the design phase and controlled throughout the CNC machining process to ensure the final part functions as intended.

Making the Right Choice for Your Goal

PTFE offers a durable and reliable solution when its properties are matched to the application's demands.

- If your primary focus is chemical resistance: PTFE's inertness provides unmatched longevity in corrosive environments, making it ideal for the chemical processing and oil and gas industries.

- If your primary focus is low-friction performance: Its self-lubricating nature is perfect for creating efficient, long-lasting seals, bearings, and sliding components.

- If your primary focus is purity and safety: Virgin PTFE is the definitive choice for medical, pharmaceutical, and food-grade applications where contamination is not an option.

- If your primary focus is thermal stability: PTFE components will maintain their structural and functional integrity in high-temperature industrial settings.

By leveraging its unique combination of material properties and machinability, you can engineer custom PTFE parts that deliver exceptional performance and reliability.

Summary Table:

| Key Property | Benefit for Industrial Parts |

|---|---|

| Chemical Inertness | Resists corrosive substances in chemical, oil & gas, and pharmaceutical applications |

| Low Friction | Self-lubricating for efficient seals, bearings, and sliding parts with minimal wear |

| High Thermal Stability | Maintains integrity at temperatures up to 500°F (260°C) |

| Excellent Machinability | Enables precise CNC fabrication of complex, custom-designed components |

| Purity & Compliance | Ideal for medical, pharmaceutical, and food-grade applications requiring FDA-approved materials |

Ready to engineer custom PTFE parts that thrive in your harsh environment?

At KINTEK, we specialize in precision manufacturing of PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in CNC machining ensures your parts meet exact specifications for chemical resistance, thermal stability, and low friction.

Whether you need a prototype or high-volume production, we deliver reliable solutions tailored to your application's demands.

Contact us today to discuss your project and discover how our custom PTFE fabrication can enhance your operational performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What types of components can be made from PTFE? Discover High-Performance Seals, Bearings & More

- What are the main benefits of PTFE slide bearings? A Low-Maintenance, High-Performance Alternative

- Why is PTFE considered an effective sealing solution for various industries? Discover the Ultimate Material for Demanding Seals

- What key factors contribute to long-term savings when using Teflon gland packing? Reduce Downtime and Maintenance Costs

- What regulatory standards does PTFE with fillers comply with? Ensuring Safety from Food to Pharma

- What is unique about PTFE waffle seals and their applications? Superior Sealing with Built-In Contamination Control

- Why are PTFE Bellows suitable for electroplating processes? Master Harsh Chemical & Thermal Environments

- What are the key benefits of using PTFE lined valves in chemical plants? Boost Safety and Cut Costs