To select the right CNC machining service for PTFE, you must look beyond general capabilities and focus on providers with specific experience in soft, thermally sensitive polymers. Key considerations include their documented expertise with PTFE, the use of high-precision machines with sharp tooling, relevant industry certifications like ISO 9001, and their ability to demonstrate a clear strategy for managing thermal expansion and material deformation during the machining process.

The central challenge with PTFE is not cutting it, but controlling its dimensions. Its unique properties—high thermal expansion and a tendency to creep under pressure—mean that true expertise lies in the machinist's process control, not just the power of their equipment.

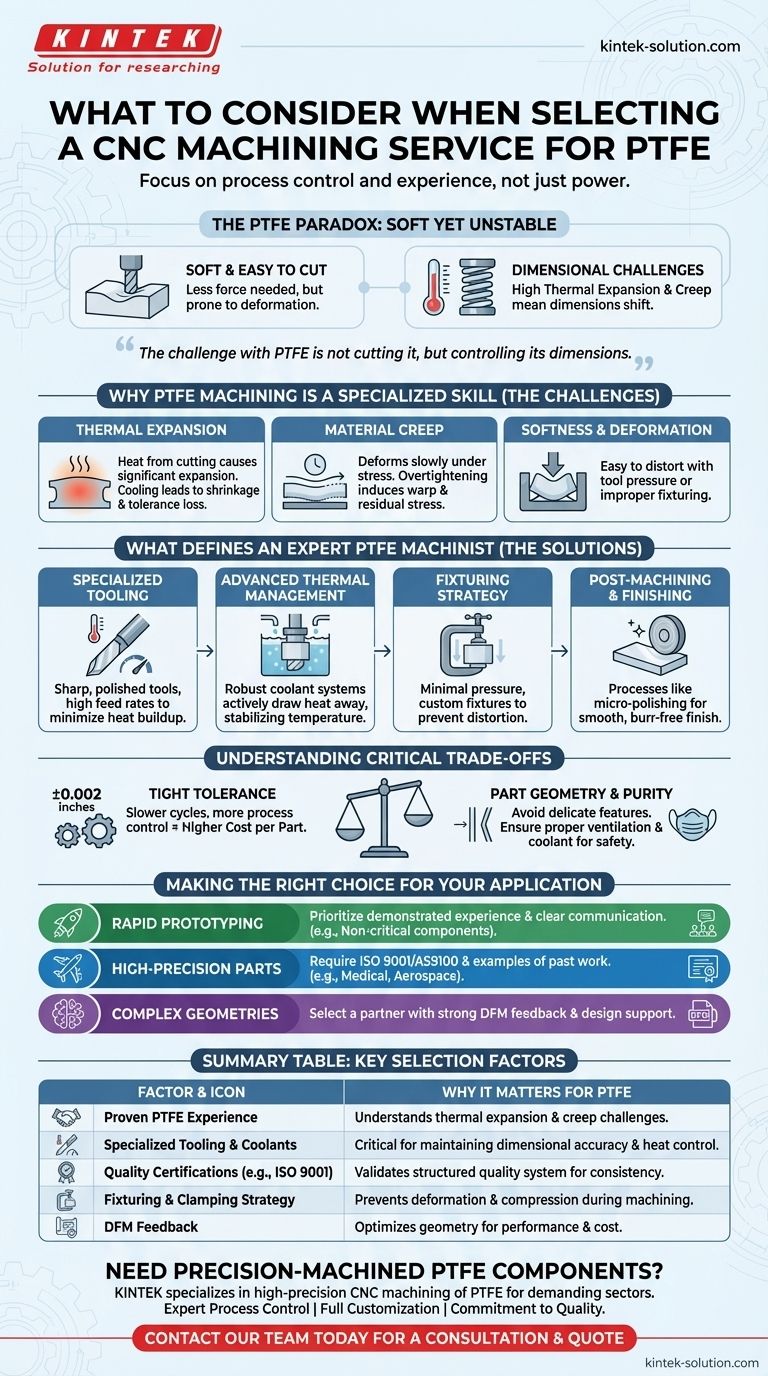

Why PTFE Machining is a Specialized Skill

General-purpose machine shops often underestimate the nuances of PTFE. While it is a soft material that is easy to cut, achieving and holding tight tolerances requires a deep understanding of its unique behaviors.

The Paradox of PTFE: Soft yet Unstable

PTFE's low density and softness make the physical act of cutting it relatively simple, requiring less force than metals or harder plastics. However, this same softness makes it prone to deformation. The primary challenge isn't removing material; it's doing so without altering the part's final shape and dimensions.

Thermal Expansion: The Primary Obstacle

PTFE has a very high coefficient of thermal expansion. The friction from cutting tools generates heat, causing the material to expand significantly during machining. If not managed, a part measured as correct while warm will shrink and fall out of tolerance once it cools to room temperature.

Material Creep and Compression

PTFE is susceptible to stress creep, meaning it will slowly deform over time when subjected to pressure. Overtightening a part in a vise or clamp during machining can compress the material. This not only results in an inaccurate cut but can also induce residual stress, causing the part to warp later.

What Defines an Expert PTFE Machinist

Verifying a provider's expertise involves asking about their specific processes for overcoming PTFE's inherent challenges. Look for evidence of the following.

Specialized Tooling and Parameters

An expert shop will use extremely sharp and polished cutting tools, often made from High-Speed Steel (HSS) or specific grades of carbide. They will also use high feed rates and moderate cutting speeds to minimize heat buildup and ensure effective chip (swarf) removal.

Advanced Thermal Management

A crucial element of success is a robust thermal management strategy. This almost always involves the use of a coolant system to flood the workpiece and cutting tool, actively drawing heat away from the cutting zone and stabilizing the material's temperature.

Fixturing and Clamping Strategy

Ask potential suppliers how they hold PTFE parts for machining. Experienced machinists use minimal clamping pressure and specialized fixtures designed to hold the part securely without causing distortion or compression.

Post-Machining and Finishing

Due to its softness, PTFE can have a "gummy" machining characteristic that affects surface finish. A quality provider will have established processes, such as micro-polishing, to achieve the required smoothness and remove any burrs without damaging the part.

Understanding the Critical Trade-offs

When specifying PTFE parts, it's essential to understand the relationship between design, tolerance, and cost.

Tolerance vs. Cost

While skilled machinists can achieve tolerances within ±0.002 inches (or even tighter), doing so requires careful process control, slower cycle times, and potentially multiple finishing steps. Tighter tolerances will directly translate to a higher cost per part.

The Impact of Part Geometry

Features like thin walls or delicate structures are particularly vulnerable to distortion from tool pressure and heat. Designing robust features and avoiding unnecessarily sharp internal corners can significantly improve manufacturability and reduce cost.

Material Purity and Safety

Machining PTFE creates fine dust particles that can be hazardous if inhaled. A professional shop will operate with proper ventilation and safety protocols, such as machining under coolant, which also serves to contain this dust. This commitment to safety often reflects a broader commitment to process quality.

Making the Right Choice for Your Application

To select the best partner, align their capabilities with your project's specific needs.

- If your primary focus is rapid prototyping or non-critical components: Prioritize a provider with demonstrated PTFE experience and a clear communication style, even if they don't hold advanced aerospace certifications.

- If your primary focus is high-precision parts for medical, aerospace, or industrial use: Require proof of their quality control system (like ISO 9001 or AS9100 certification) and ask to see examples of past work with similar tolerances.

- If your primary focus is complex geometries with delicate features: Select a partner who offers strong technical support and Design for Manufacturability (DFM) feedback to help optimize your design before production begins.

Ultimately, choosing the right partner is about verifying their deep understanding of the material, not just their machining capacity.

Summary Table:

| Key Selection Factor | Why It Matters for PTFE |

|---|---|

| Proven PTFE Experience | Ensures understanding of material-specific challenges like thermal expansion and creep. |

| Specialized Tooling & Coolants | Sharp tools and thermal management are critical for maintaining dimensional accuracy. |

| Quality Certifications (e.g., ISO 9001) | Validates a structured quality management system for consistent results. |

| Fixturing & Clamping Strategy | Prevents part deformation and compression during the machining process. |

| Design for Manufacturability (DFM) Feedback | Helps optimize part geometry for better performance and lower cost. |

Need Precision-Machined PTFE Components?

KINTEK specializes in the high-precision CNC machining of PTFE for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand the critical nature of managing PTFE's thermal expansion and material stability to hold tight tolerances.

We provide:

- Expert Process Control: Our specialized techniques manage heat and stress to ensure dimensional accuracy.

- Full Customization: From initial prototypes to high-volume production runs.

- Commitment to Quality: Precision production is our priority, delivering reliable parts for your critical systems.

Let us put our PTFE expertise to work for you. Contact our team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why might PTFE gaskets fail in sanitary applications? The Hidden Mechanical Flaws in a Chemically Perfect Material

- What are the advantages of CNC machining for PTFE components? Achieve Unmatched Precision for Complex Parts

- What is expanded PTFE (ePTFE) and how is it produced? Unlock Superior Sealing and Insulation

- In what types of environments are PTFE seat butterfly valves most suitable? Ideal for Corrosive, High-Purity Applications

- What are the key characteristics of Polytetrafluoroethylene (PTFE) in gland packings? Maximize Sealing Performance

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- How does Teflon lining on the internal wall of valves improve performance? Enhance Valve Life and Purity

- How does the large expansion coefficient of PTFE material affect processing? Master Dimensional Stability