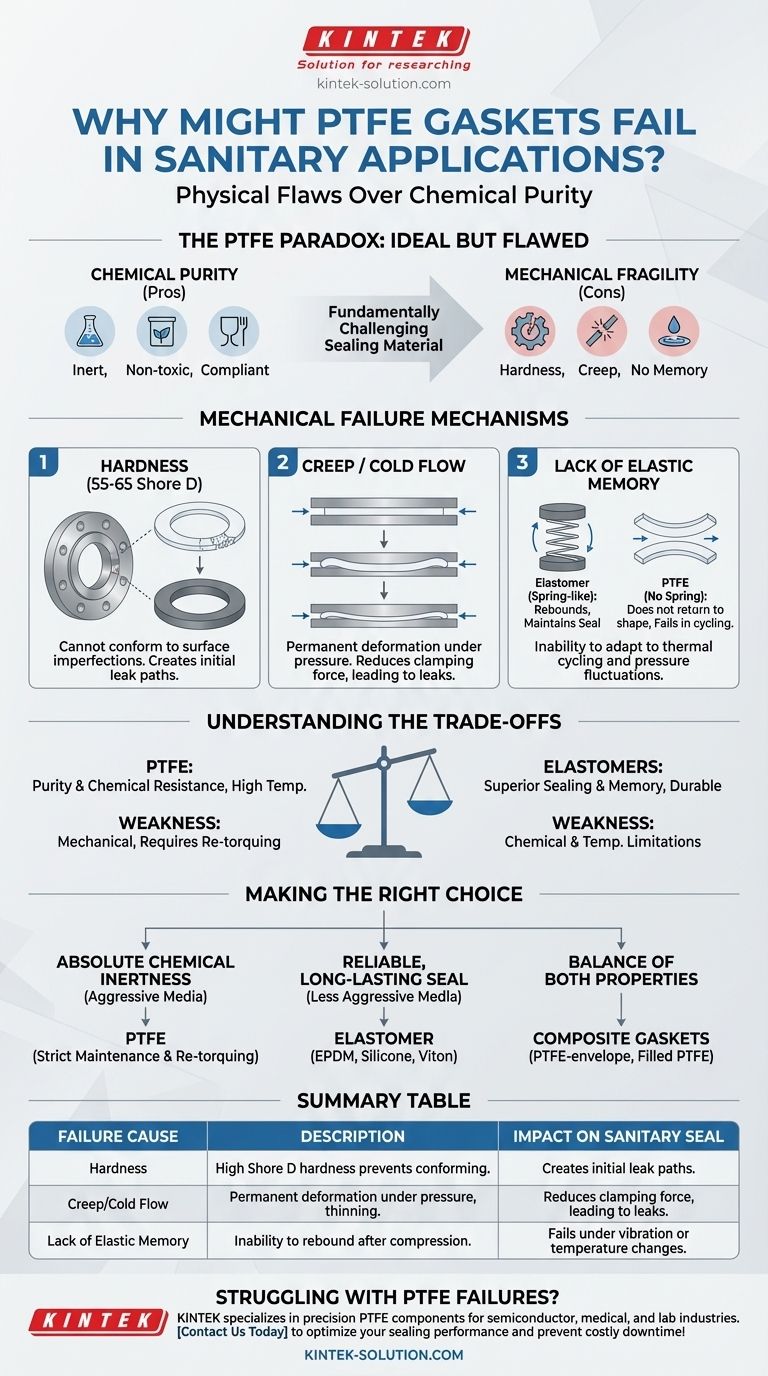

In short, PTFE gaskets primarily fail in sanitary applications due to their physical, not chemical, properties. The material's inherent hardness prevents it from creating a perfect seal, and its tendency to permanently deform under pressure—a phenomenon known as creep or cold flow—causes the seal to loosen over time, leading to leaks.

The central issue with PTFE is a paradox: while its chemical inertness makes it ideal for preventing contamination in sanitary systems, its mechanical rigidity and lack of memory make it a fundamentally challenging sealing material.

Why an Ideal Material Becomes a Liability

PTFE (Polytetrafluoroethylene) is a default choice in many food, dairy, and pharmaceutical applications for one critical reason: its purity. However, the properties that make it a poor sealing material are baked into its molecular structure.

The Purity Advantage

PTFE is renowned for being one of the most chemically inert substances available. It is non-toxic and does not leach chemicals into the product it contacts.

This ensures it complies with strict health and safety regulations, making it a trusted material for preventing product contamination.

The Problem of Hardness

The first mechanical flaw is hardness. Gaskets seal by deforming to fill microscopic imperfections in the metal flange surfaces they are pressed between.

PTFE has a hardness of 55-65 on the Shore D scale. In contrast, common elastomer gaskets (like rubber) are much softer, typically around 70 on the Shore A scale. A harder material simply cannot conform as well, creating potential leak paths from the start.

The Concept of "Creep" or "Cold Flow"

The most significant cause of failure is creep, also known as cold flow. This is the tendency of a solid material to move or deform permanently under the influence of persistent stress.

When a PTFE gasket is tightened in a sanitary fitting, it is under constant compressive force. Over time, the material "flows" outward, away from the pressure. This thins the gasket and reduces the clamping force, eventually compromising the seal.

The Lack of Elastic Memory

Compounding the problem of creep is PTFE's near-total lack of elastic memory. An elastomer gasket acts like a spring; when compressed, it constantly pushes back, maintaining a live seal.

PTFE has no such "springiness." Once it deforms or creeps, it does not return to its original shape. This means it cannot adapt to thermal cycling (system heating and cooling) or pressure fluctuations, which are common causes of gasket failure.

Understanding the Trade-offs

Choosing a gasket material is always a matter of balancing competing properties. The decision between PTFE and an elastomer highlights a classic engineering trade-off.

PTFE: Chemical Purity vs. Mechanical Fragility

This material offers unparalleled resistance to chemicals and high temperatures, along with total product purity. However, it is mechanically unforgiving and requires precise installation and frequent re-tightening to compensate for creep.

Elastomers: Superior Sealing vs. Chemical Limitations

Materials like EPDM or Viton offer excellent elasticity and memory, creating a more reliable and forgiving seal that can handle vibration and temperature changes. Their weakness lies in their limited chemical compatibility and lower temperature ratings compared to PTFE.

Making the Right Choice for Your System

To mitigate failure, you must align your gasket material's properties with the specific demands of your sanitary application.

- If your primary focus is absolute chemical inertness for aggressive media: PTFE is often necessary, but you must implement a strict re-torquing and replacement schedule to counteract inevitable gasket creep.

- If your primary focus is a reliable, long-lasting seal for less aggressive media: A high-quality, sanitary-grade elastomer like EPDM, silicone, or Viton will provide a more durable and forgiving sealing solution.

- If you need a balance of both properties: Consider advanced composite gaskets, such as PTFE-envelope gaskets or filled PTFE, which combine a chemically inert surface with a more mechanically stable core.

Ultimately, understanding these fundamental material properties empowers you to select and manage your sanitary gaskets for maximum reliability and safety.

Summary Table:

| Failure Cause | Description | Impact on Sanitary Seal |

|---|---|---|

| Hardness | High Shore D hardness (55-65) prevents conforming to flange imperfections. | Creates initial leak paths; poor surface adaptation. |

| Creep/Cold Flow | Permanent deformation under constant pressure, thinning the gasket over time. | Reduces clamping force, leading to gradual loosening and leaks. |

| Lack of Elastic Memory | Inability to rebound after compression or thermal cycling. | Fails to maintain seal under vibration or temperature changes. |

Struggling with PTFE gasket failures in your sanitary systems? At KINTEK, we specialize in precision PTFE components—including custom seals, liners, and labware—for semiconductor, medical, and laboratory industries. Our expertise in material science and custom fabrication ensures solutions that balance chemical inertness with mechanical reliability, from prototypes to high-volume orders. Contact us today to discuss how we can optimize your sealing performance and prevent costly downtime!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability