At its core, the large thermal expansion coefficient of Polytetrafluoroethylene (PTFE) makes the material highly sensitive to temperature fluctuations. This property demands exceptionally precise temperature control during any processing or machining, as even minor changes can cause significant dimensional inaccuracies and compromise the quality of the final part.

The challenge with PTFE is not merely its expansion, but the magnitude of that expansion. This single property dictates the entire manufacturing approach, turning temperature control from a standard procedure into the most critical factor for success.

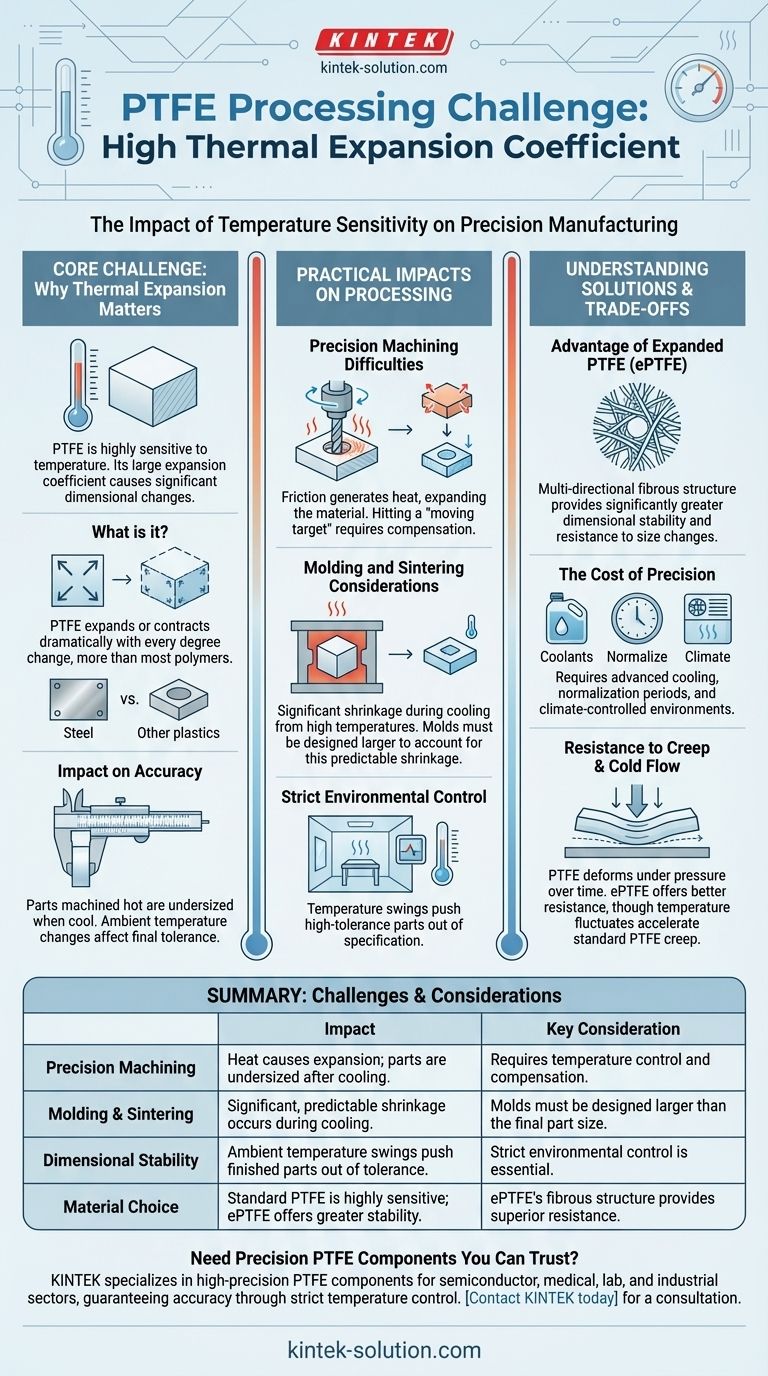

The Core Challenge: Why Thermal Expansion Matters

The physical properties of a material define how it can be successfully transformed into a finished product. For PTFE, its relationship with heat is the most important consideration.

What is a High Coefficient of Thermal Expansion?

The coefficient of thermal expansion is a measure of how much a material changes in size (expands or contracts) when its temperature changes.

PTFE has one of the highest coefficients of thermal expansion among common polymers. This means for every degree of temperature change, it grows or shrinks much more dramatically than materials like steel or even other plastics.

The Impact on Dimensional Accuracy

This high expansion rate is the primary source of processing difficulty. A part machined to precise specifications at one temperature will be out of tolerance if the ambient or material temperature changes.

Heat generated during the machining process itself can cause the material to expand, leading to an undersized part once it cools to its final operating temperature.

Practical Impacts on Processing and Fabrication

This fundamental property creates specific, tangible challenges that must be addressed in any manufacturing environment working with PTFE.

Precision Machining Difficulties

During cutting, drilling, or milling, friction generates heat. As the PTFE heats up, it expands. If the machinist is targeting a specific dimension, they are essentially hitting a moving target.

The final part, once cooled, will inevitably be smaller than the dimension measured during the hot machining process. This requires careful compensation or advanced cooling techniques.

Molding and Sintering Considerations

PTFE is often formed through a process of compression and sintering (heating below its melting point). The part is formed at a high temperature and then cooled.

Due to its high expansion coefficient, the amount of shrinkage during cooling is substantial. Molds must be designed to be larger than the final desired part size to account for this predictable shrinkage.

The Need for Strict Environmental Control

For high-tolerance applications, the temperature of the entire manufacturing facility becomes a critical variable.

A temperature swing of just a few degrees from morning to afternoon can be enough to push a precisely machined PTFE component out of its specified tolerance range.

Understanding the Solutions and Trade-offs

Managing PTFE's thermal expansion isn't just about controlling the environment; it's also about choosing the right form of the material for the job.

The Advantage of Expanded PTFE (ePTFE)

One effective solution is to use a modified form of the material, such as expanded PTFE (ePTFE).

This material is processed to create a multi-directional fibrous structure. This structure provides significantly greater dimensional stability, making it less susceptible to size changes caused by temperature.

The Inescapable Cost of Precision

Achieving the necessary level of temperature control adds complexity, time, and cost to the manufacturing process.

Using coolants, allowing for material normalization periods, and maintaining a climate-controlled environment are necessary expenses for producing reliable PTFE parts.

Resistance to Creep and Cold Flow

A related challenge is PTFE's tendency to deform under pressure over time, a phenomenon known as creep or cold flow.

While ePTFE offers better resistance to this, temperature fluctuations can accelerate creep in standard PTFE, further complicating its use in stable, load-bearing applications.

Making the Right Choice for Your Goal

Successfully processing PTFE requires aligning your manufacturing strategy with the demands of the material and the goals of the final product.

- If your primary focus is high-precision components: You must implement strict, active temperature controls and account for thermal shrinkage in all design and machining calculations.

- If your primary focus is dimensional stability across a range of temperatures: Consider using multi-directionally expanded PTFE (ePTFE), which is engineered specifically to resist thermal expansion.

- If your primary focus is a sealed connection: Recognize that a PTFE gasket will expand and contract with temperature, and ensure your flange design can accommodate these changes without losing the seal.

Ultimately, mastering PTFE means treating temperature not as a background condition, but as a critical design and processing parameter.

Summary Table:

| Challenge | Impact on Processing | Key Consideration |

|---|---|---|

| Precision Machining | Heat from friction causes expansion; parts are undersized after cooling. | Requires temperature control and compensation in machining calculations. |

| Molding & Sintering | Significant, predictable shrinkage occurs during cooling from high temperatures. | Molds must be designed larger than the final part size to account for shrinkage. |

| Dimensional Stability | Ambient temperature swings can push finished parts out of tolerance. | Strict environmental control is essential for high-tolerance applications. |

| Material Choice | Standard PTFE is highly sensitive; expanded PTFE (ePTFE) offers greater stability. | ePTFE's fibrous structure provides superior resistance to thermal expansion. |

Need Precision PTFE Components You Can Trust?

Mastering the thermal expansion of PTFE is critical for part performance. At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures strict temperature control and precise fabrication from prototypes to high-volume orders, guaranteeing dimensional accuracy and reliability.

Let us solve your PTFE processing challenges. Contact KINTEK today for a consultation on your custom project!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers