In essence, Teflon lining transforms a standard valve by creating a chemically inert, low-friction, and non-stick barrier on its internal surfaces. This composite design protects the valve's structural metal body from corrosion while simultaneously ensuring smoother media flow, reducing operational wear, and preventing process contamination.

The core value of Teflon lining is not just adding protection; it's a strategic engineering choice. It allows you to achieve the extreme chemical resistance of an exotic material without the high cost or the structural limitations of pure PTFE, directly improving system reliability and profitability.

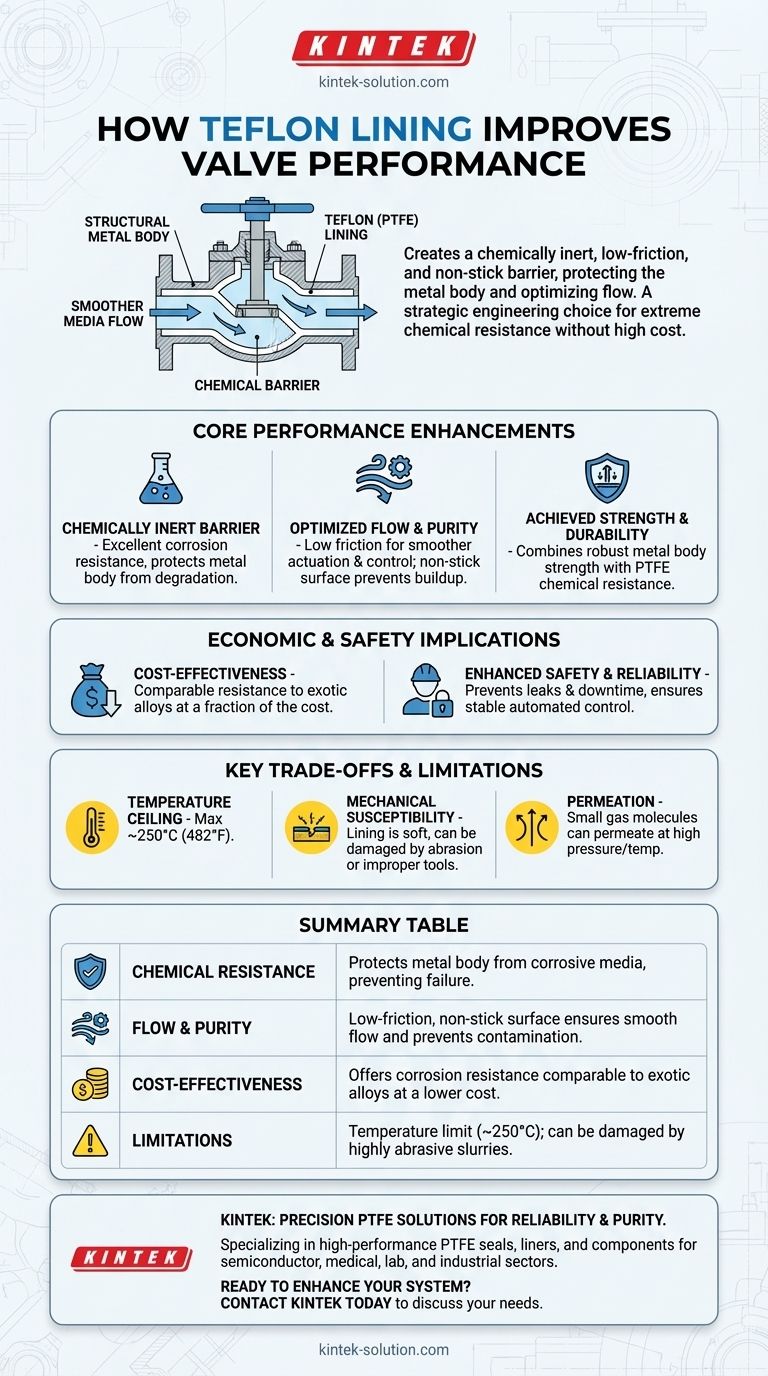

The Core Performance Enhancements of Teflon Lining

A Teflon-lined valve combines the strength of a metal exterior with the unique properties of a Polytetrafluoroethylene (PTFE) interior. This synergy solves several critical challenges in fluid and gas handling.

Creating a Chemically Inert Barrier

The primary function of the Teflon lining is to provide exceptional corrosion resistance. PTFE is virtually inert to almost all industrial chemicals and solvents.

By lining the internal wetted parts of the valve, you effectively isolate the structural metal (like carbon or stainless steel) from the corrosive process media. This prevents chemical degradation and failure of the valve's body.

Optimizing Flow and Minimizing Contamination

Teflon is known for having one of the lowest coefficients of friction of any solid material. This property has a direct impact on performance.

It ensures smoother valve actuation and more precise flow control, as the internal components move with less resistance.

Furthermore, the non-stick surface prevents process media from adhering to the valve's interior. This minimizes material buildup, reduces the risk of cross-contamination between batches, and simplifies cleaning procedures.

Achieving Strength and Durability

While pure, solid PTFE offers incredible chemical resistance, it has low mechanical strength and is unsuitable for high-pressure applications.

A lined valve solves this by using a robust metal body that handles the system pressure, impacts, and pipe stress. The Teflon lining simply serves as a protective barrier, giving you the best of both worlds.

Understanding the Economic and Safety Implications

Choosing a valve is a decision that impacts not just the immediate process, but also long-term operational cost and system safety. Teflon lining offers a distinct advantage in this context.

The Cost-Effectiveness Advantage

For highly corrosive services, the alternative is often a valve constructed entirely from an expensive, exotic alloy like Hastelloy or Monel.

Lining a standard, lower-cost metal valve with Teflon provides comparable chemical resistance at a fraction of the cost. This makes it a highly pragmatic and economical solution for managing aggressive media.

Enhancing System Safety and Reliability

Valve failure can lead to dangerous leaks, process downtime, and significant financial loss. By preventing corrosion, Teflon lining directly enhances the long-term integrity and safety of the system.

In automated systems, the smooth and predictable operation of a non-stick valve is critical for the stability of the control loop. A sticking or worn valve can cause process oscillations that negatively affect product quality and profitability.

Key Trade-offs and Limitations

While highly effective, a Teflon-lined valve is not a universal solution. Understanding its limitations is crucial for proper application.

Temperature Ceiling

The high-temperature resistance of PTFE is excellent for a polymer, typically up to 250°C (482°F). However, this is an absolute limit. Processes that exceed this temperature require valves made from specialized metal alloys.

Susceptibility to Mechanical Damage

The Teflon lining is a relatively soft material. It can be scratched or gouged by highly abrasive slurries (e.g., those containing sharp, hard particles) or damaged by improper maintenance tools. Any breach in the lining exposes the metal body to corrosion, negating the valve's primary benefit.

Permeation with Certain Gases

In high-pressure and high-temperature applications, very small gas molecules (like hydrogen or chlorine) can sometimes slowly permeate through the PTFE lining over long periods. While not an issue for most applications, this can be a consideration for certain ultra-high-purity or highly sensitive chemical processes.

Making the Right Choice for Your Application

Selecting the correct valve requires aligning its capabilities with your specific operational goals.

- If your primary focus is handling highly corrosive media on a budget: A Teflon-lined valve is often the most cost-effective solution over expensive exotic alloys.

- If your primary focus is process purity and preventing buildup: The non-stick, low-friction surface is ideal for applications in pharmaceuticals, food processing, or where smooth flow is critical.

- If your primary focus is high-pressure service with abrasive materials: You must carefully evaluate if the lining can withstand the mechanical wear, as any physical damage would compromise its protective function.

Ultimately, selecting a Teflon-lined valve is an informed engineering decision that balances chemical resistance, mechanical durability, and overall system cost.

Summary Table:

| Performance Aspect | Key Benefit of Teflon Lining |

|---|---|

| Chemical Resistance | Protects metal body from corrosive media, preventing failure. |

| Flow & Purity | Low-friction, non-stick surface ensures smooth flow and prevents contamination. |

| Cost-Effectiveness | Offers corrosion resistance comparable to exotic alloys at a lower cost. |

| Limitations | Temperature limit (~250°C/482°F); can be damaged by highly abrasive slurries. |

Ready to enhance your system's reliability and purity with precision-engineered PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication—from prototypes to high-volume orders—to deliver solutions that protect your equipment and processes.

Contact KINTEK today to discuss your specific application needs and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & High-Temp Environments

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- In what types of applications is EPDM more effective than PTFE for wafer style butterfly valves? Optimize for Water & Steam Systems

- What key factors contribute to long-term savings when using Teflon gland packing? Reduce Downtime and Maintenance Costs

- What are the primary applications of PTFE envelope gaskets? The Ideal Seal for Aggressive Chemicals & Fragile Flanges

- How do Medical Grade PTFE Liners perform under extreme conditions? Ensure Unmatched Reliability from -200°C to 260°C

- What are the limitations of PTFE gaskets in high-pressure applications? Overcoming Cold Flow & Creep Issues

- What are the desirable properties of PTFE as a sealing material? Unlock Superior Performance in Extreme Conditions