In the context of gland packings, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer prized for its unique combination of properties. It offers near-universal chemical resistance, an exceptionally low coefficient of friction for self-lubrication, and excellent stability across a wide range of operating temperatures, making it a superior choice for many demanding industrial sealing applications.

While many materials can provide a seal, PTFE excels in aggressive chemical environments and high-friction applications where other packings would quickly degrade or damage equipment. Its value lies in preventing chemical attack and minimizing wear, but success requires respecting its specific thermal and pressure limitations.

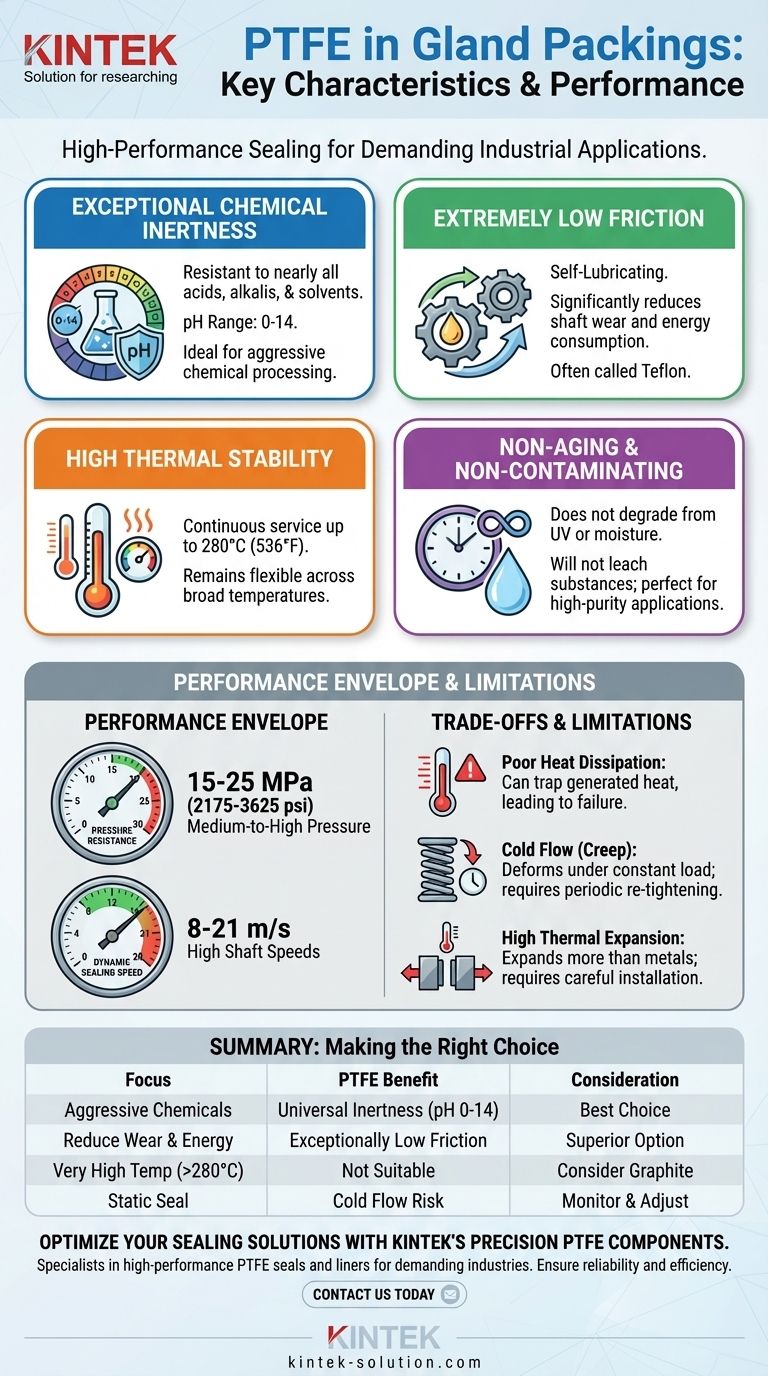

The Core Properties of PTFE in Sealing Applications

To understand why PTFE is so widely used in pumps and valves, we must examine the fundamental properties that define its performance. These characteristics stem from its unique molecular structure, which consists of a strong carbon-fluorine backbone.

Exceptional Chemical Inertness

PTFE is famous for being one of the most chemically inert materials known. It is virtually immune to attack from almost all industrial chemicals, including strong acids, alkalis, corrosive agents, and solvents.

Gland packings made from PTFE can operate across the entire pH range of 0 to 14. This makes it an incredibly versatile material for chemical processing, pharmaceuticals, and any service where the process fluid is aggressive.

Extremely Low Coefficient of Friction

Often known by its trade name Teflon, PTFE has one of the lowest friction coefficients of any solid material. This property is often described as self-lubricating.

In a gland packing application, this means significantly less friction on the pump shaft or valve stem. The benefits are direct: reduced wear on expensive equipment, lower heat generation at the sealing point, and decreased energy consumption for the motor driving the equipment.

High Thermal Stability

PTFE remains flexible and effective across a broad temperature spectrum. Pure PTFE packings are typically rated for continuous service up to 280°C (536°F).

It's important to distinguish this from its melting point, which is higher at around 327°C (620°F). Exceeding the service temperature can cause the material to degrade and lose its sealing properties.

Non-Aging and Non-Contaminating

Unlike natural fiber packings that can dry out, rot, or become brittle over time, PTFE is non-aging. It does not degrade when exposed to UV light, moisture, or environmental factors, ensuring a long and predictable service life.

Furthermore, its inertness means it will not leach substances into the process media. This lack of contamination is critical for applications in the food and beverage, pharmaceutical, and high-purity electronics industries.

Understanding the Performance Envelope

While its properties are impressive, a material is only as good as its performance within a specific operational window. For PTFE gland packings, these parameters define its practical limits.

Pressure Resistance

PTFE gland packings are suitable for medium-to-high pressure services. Typical ratings fall within the 15 to 25 MPa (approximately 2175 to 3625 psi) range. The specific pressure rating can be influenced by the packing's construction, such as the type of braid and any reinforcing fibers.

Dynamic Sealing Speed (Line Speed)

The low friction of PTFE allows it to be used in equipment with relatively fast-moving shafts. It is often rated for line speeds between 8 and 21 m/s. This makes it suitable for many centrifugal pumps and other rotating equipment where high shaft speeds would generate excessive, damaging heat with other packing materials.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's weaknesses to prevent misapplication and failure.

Poor Heat Dissipation

While PTFE's low friction reduces heat generation, the material itself is a poor thermal conductor. Any heat that is generated does not dissipate well through the packing. This is a primary reason for its speed and temperature limits; exceeding them can trap heat, leading to premature packing failure.

Cold Flow (Creep)

Under a constant compressive load, such as the force applied by the gland follower, PTFE has a tendency to slowly deform or "flow" over time. This phenomenon, known as creep, can cause a loss of sealing pressure. It may require the gland to be periodically re-tightened to maintain a leak-free seal.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. It will expand and contract more significantly with temperature changes. This must be accounted for during installation, as a packing installed cold may exert excessive pressure on the shaft when the system heats up to operating temperature.

Making the Right Choice for Your Service

Your choice of gland packing should be a direct response to your primary operational challenge.

- If your primary focus is aggressive chemicals: PTFE is almost always the correct choice due to its near-universal chemical inertness.

- If your primary focus is reducing shaft wear and energy use: PTFE's exceptionally low friction makes it a superior option over more abrasive packing materials.

- If your primary focus is very high temperatures (above 280°C / 536°F): You should consider alternatives like graphite packing, which is designed for higher thermal loads.

- If your primary focus is a "set-and-forget" static seal: Be mindful of PTFE's potential for cold flow, as it may require periodic adjustments to maintain ideal sealing stress.

By understanding these core characteristics and operational limits, you can confidently leverage PTFE to enhance the reliability and efficiency of your critical sealing applications.

Summary Table:

| Key Characteristic | Description | Benefit in Gland Packings |

|---|---|---|

| Chemical Inertness | Resistant to nearly all chemicals (pH 0-14) | Ideal for aggressive chemical environments |

| Low Coefficient of Friction | Self-lubricating, reduces friction | Minimizes shaft wear and energy consumption |

| Thermal Stability | Operates up to 280°C (536°F) | Suitable for high-temperature applications |

| Pressure Resistance | Handles 15-25 MPa (2175-3625 psi) | Reliable in medium-to-high pressure services |

| Limitations | Poor heat dissipation, cold flow, high thermal expansion | Requires careful installation and monitoring |

Optimize your sealing solutions with KINTEK's precision PTFE components.

As specialists in manufacturing high-performance PTFE seals, liners, and custom labware for semiconductor, medical, laboratory, and industrial sectors, we ensure your equipment operates reliably under the most demanding conditions. Whether you need prototypes or high-volume orders, our expertise in PTFE properties guarantees a perfect fit for your application.

Contact us today to discuss your specific requirements and enhance your system's efficiency and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the difference between Teflon valves and PTFE lined valves? Choose the Right Valve for Your System

- What are the main differences between RPTFE and standard PTFE for valve seats? Choose the Right Material for Your System

- Why are PTFE envelope gaskets suitable for food processing and pharmaceutical applications? Ensure Product Purity and Compliance

- What happens when using a soft rotary shaft with PTFE seals? Avoid Premature Wear and System Failure

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What makes PTFE O-rings durable over time? The Secret to Long-Lasting Seals in Harsh Conditions

- How is PTFE processed into usable shapes? From Powder to Precision Parts

- What are the advantages of virgin PTFE for industrial applications? Unmatched Purity & Performance