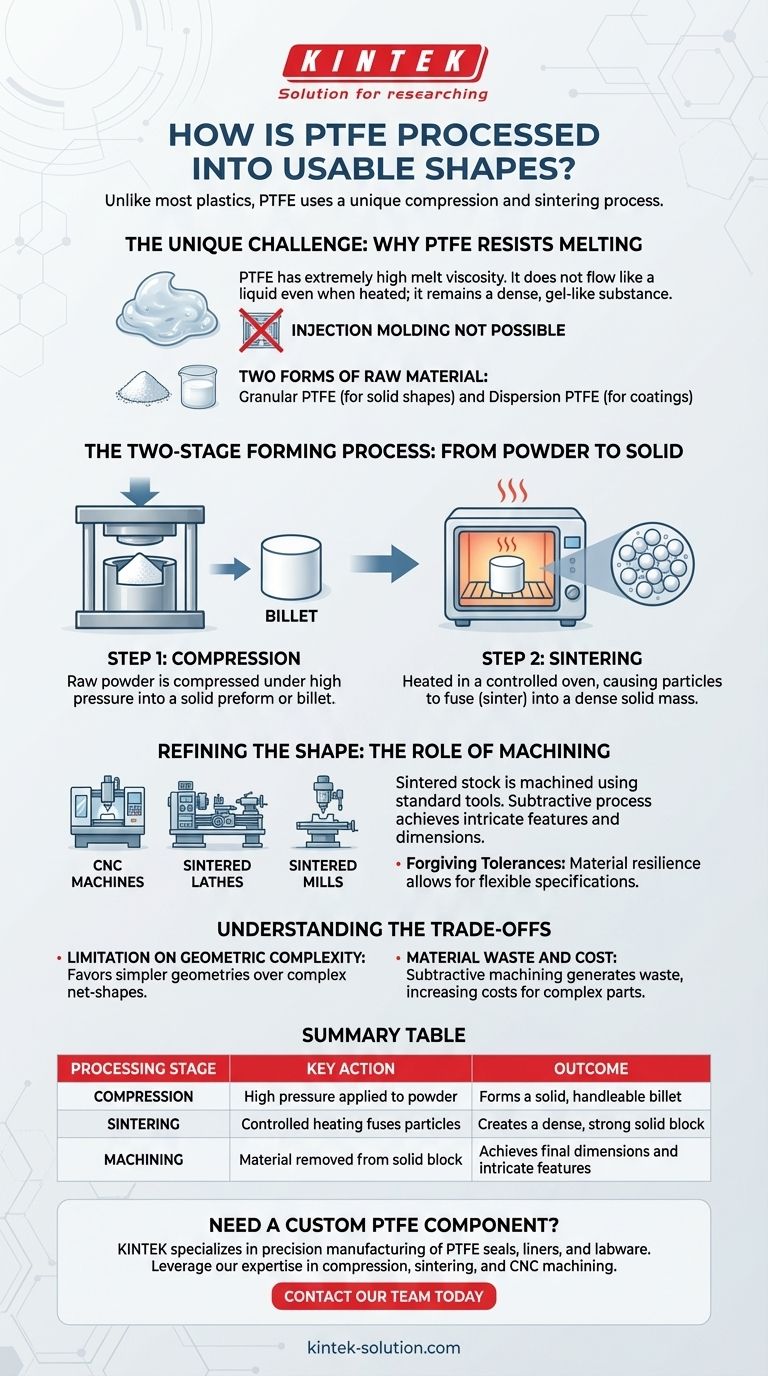

Unlike most plastics, Polytetrafluoroethylene (PTFE) cannot be processed by melting. Instead, the raw PTFE powder is first compressed into a solid block, known as a billet, and then heated in a process called sintering, which fuses the particles together. This solid form is then easily machined into its final, usable shape using standard cutting tools.

The core takeaway is that processing PTFE is a multi-stage method more akin to powder metallurgy than traditional plastic molding. This fundamental difference—compressing and sintering a powder rather than melting and injecting a liquid—directly influences part design, complexity, and cost.

The Unique Challenge: Why PTFE Resists Melting

To understand how PTFE is shaped, you must first understand its fundamental properties. It behaves very differently from common polymers like ABS or polycarbonate.

A Polymer That Won't Flow

PTFE has an extremely high melt viscosity, meaning even at temperatures where it technically begins to melt, it doesn't flow like a liquid. It remains a very dense, gel-like substance.

Because it cannot be liquefied and injected into a mold, traditional high-volume methods like injection molding are not possible. The material must be formed while it is in a solid state.

The Two Forms of Raw Material

The process begins with PTFE created through one of two polymerization methods, which yield different raw forms for different applications.

Suspension polymerization creates granular PTFE grains or pellets. This is the material used to create solid shapes like rods, sheets, and tubes.

Dispersion polymerization produces a fine, milky paste. This form is primarily used to create thin coatings for applications like non-stick cookware.

The Two-Stage Forming Process: From Powder to Solid

Creating a solid PTFE component is a sequential process that builds a dense, usable part from loose powder.

Step 1: Compression

The raw, granular PTFE powder is poured into a mold and subjected to high pressure. This compacts the powder into a solid "preform" or billet that is strong enough to be handled.

This initial shape is a simple, rough approximation of the final part, such as a solid cylinder, block, or thick-walled tube.

Step 2: Sintering

The compressed billet is removed from the mold and heated in a carefully controlled oven. The temperature is brought high enough to cause the individual PTFE particles to fuse, or sinter, into a single, solid mass.

This is the most critical step, as it locks the particles together, giving the material its final strength and density without ever having to melt it.

Refining the Shape: The Role of Machining

Once a sintered billet is produced, it serves as the raw stock material for creating the final component.

Subtractive Manufacturing is Key

PTFE is remarkably easy to machine using standard equipment. CNC machines, lathes, mills, and drills can all cut PTFE cleanly and precisely.

This subtractive process, where material is removed from a solid block, is how intricate features, tight tolerances, and final dimensions are achieved.

Forgiving Tolerances

Due to PTFE's natural resilience and low friction, it can often conform to its working environment. This means that while extremely close tolerances can be achieved, they are often not necessary for the part to function correctly.

Because of this, stock PTFE shapes are often sold slightly oversized, allowing fabricators to easily machine them down to exact specifications.

Understanding the Trade-offs

The compression, sintering, and machining process has direct consequences for design and manufacturing.

Limitation on Geometric Complexity

Because PTFE isn't injection molded, creating highly complex, net-shape parts is difficult and expensive. The process favors simpler geometries that can be easily machined from standard stock shapes like rods and sheets.

Material Waste and Cost

Subtractive machining, by its nature, generates waste material. For complex parts requiring significant material removal, this can increase the overall cost compared to a molded plastic part where only the necessary material is used.

How to Apply This to Your Project

Choosing the right approach depends entirely on your final goal.

- If your primary focus is a simple component like a gasket, seal, or bushing: Standard, pre-formed PTFE rods and sheets are ideal stock materials for simple machining.

- If your primary focus is a complex, custom-machined part: Design your component with subtractive manufacturing in mind, and be aware that costs will scale with complexity and material waste.

- If your primary focus is a surface coating: You need PTFE produced via the dispersion method, which is applied as a liquid or fine powder and then cured with heat.

Understanding this unique manufacturing path is the key to effectively leveraging PTFE's exceptional properties while respecting its practical design constraints.

Summary Table:

| Processing Stage | Key Action | Outcome |

|---|---|---|

| Compression | High pressure applied to powder | Forms a solid, handleable billet |

| Sintering | Controlled heating fuses particles | Creates a dense, strong solid block |

| Machining | Material removed from solid block | Achieves final dimensions and intricate features |

Need a custom PTFE component? KINTEK specializes in precision manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, and industrial sectors. Our expertise in compression, sintering, and CNC machining ensures your parts meet exact specifications, from prototypes to high-volume orders. Contact our team today to discuss your project and leverage our material knowledge for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers