The primary advantage of virgin PTFE is its absolute purity. Because it contains no fillers, additives, or recycled content, its performance is exceptionally consistent and reliable. This inherent purity is the foundation for its most valued industrial properties: superior chemical inertness, a remarkably low coefficient of friction, and unwavering stability in high-purity and high-heat environments.

While many materials are chosen for a single characteristic, the true value of virgin PTFE lies in the guarantee of performance consistency. Its purity ensures that its elite chemical resistance, thermal stability, and lubricity are predictable and repeatable, a non-negotiable requirement for mission-critical applications.

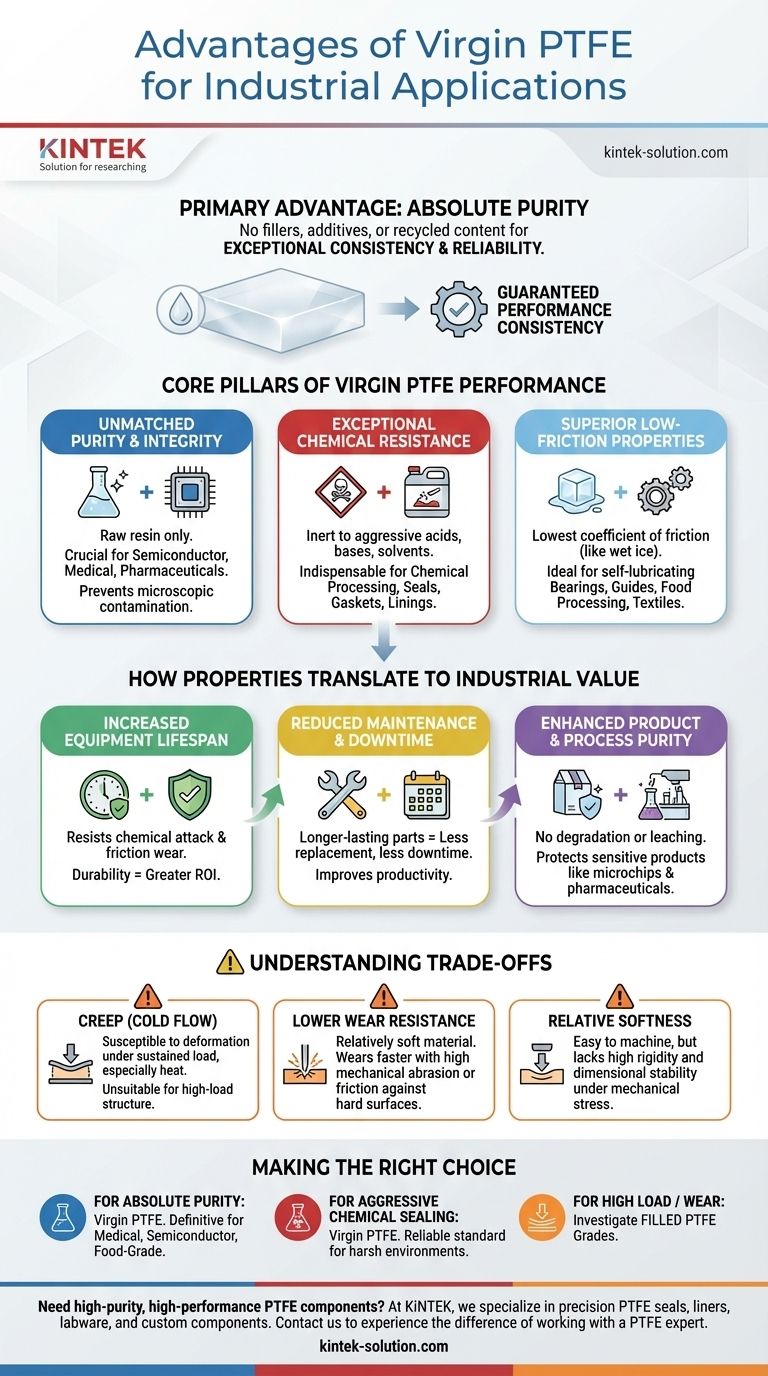

The Core Pillars of Virgin PTFE Performance

Virgin Polytetrafluoroethylene (PTFE) is a specialized fluoropolymer known for a unique combination of properties. Understanding these core attributes clarifies why it is the material of choice for some of the most demanding industrial sectors.

Unmatched Purity and Material Integrity

The term "virgin" signifies that the PTFE is manufactured directly from raw resin without any added fillers or re-processed materials.

This absolute purity is critical in industries where even microscopic contamination can cause catastrophic failure. Applications in semiconductor manufacturing, medical devices (implants, catheters), and pharmaceuticals rely on virgin PTFE to ensure no unintended substances are introduced into a process or product.

Exceptional Chemical Resistance

Virgin PTFE is chemically inert to nearly all known industrial chemicals, including aggressive acids, bases, and organic solvents.

This property makes it an indispensable material for components in chemical processing and pharmaceutical manufacturing. Seals, gaskets, and linings made from virgin PTFE maintain their structural integrity, preventing leaks and equipment degradation even under constant exposure to corrosive substances.

Superior Low-Friction Properties

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it an ideal self-lubricating material.

It is frequently used for mechanical parts like bearings, piston rings, and machine tool guide rails in industries—such as food processing or textiles—where traditional oil-based lubricants would contaminate the final product.

How These Properties Translate to Industrial Value

The technical characteristics of virgin PTFE deliver tangible operational and financial benefits, moving beyond simple material specifications to impact the bottom line.

Increased Equipment Lifespan

By resisting both chemical attack and wear from friction, components made from virgin PTFE simply last longer. This durability leads to a greater return on investment for critical equipment.

Reduced Maintenance and Downtime

Longer-lasting parts directly translate to a reduced need for replacements and less frequent maintenance schedules. For any industrial operation, minimizing downtime is a primary driver of productivity and profitability.

Enhanced Product and Process Purity

In high-purity applications, the material's stability is paramount. Virgin PTFE does not degrade or leach substances into its environment, protecting the integrity of sensitive products like microchips or pharmaceutical compounds.

Understanding the Trade-offs of Virgin PTFE

No material is perfect for every situation. While virgin PTFE offers exceptional performance in specific areas, its limitations are just as important to understand for proper application. Its primary trade-offs are most apparent when compared to filled PTFE grades.

Susceptibility to Creep (Cold Flow)

Under a sustained mechanical load, especially at elevated temperatures, virgin PTFE has a tendency to slowly and permanently deform. This property, known as creep or cold flow, makes it unsuitable for high-load structural components.

Lower Wear Resistance

While its low friction reduces wear, virgin PTFE is a relatively soft material. In applications with high mechanical abrasion or friction against hard surfaces, it will wear more quickly than harder polymers or PTFE grades that have been filled with agents like glass, carbon, or graphite to improve durability.

Relative Softness

The same softness that makes virgin PTFE easy to machine can be a disadvantage in applications that require high rigidity and dimensional stability under mechanical stress.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal. Virgin PTFE is an elite performer, but only within the right context.

- If your primary focus is absolute purity and avoiding contamination: Virgin PTFE is the definitive choice for medical, semiconductor, and food-grade applications where material integrity is paramount.

- If your primary focus is sealing aggressive chemicals: Virgin PTFE's broad chemical inertness makes it a reliable standard for seals, gaskets, and linings that must withstand harsh environments.

- If your primary focus is high mechanical load or wear resistance: You should investigate filled PTFE grades, as virgin PTFE's softness and tendency to creep may be limiting factors.

Ultimately, choosing virgin PTFE is a decision to prioritize performance consistency and material purity above all else.

Summary Table:

| Property | Benefit for Industrial Applications |

|---|---|

| Absolute Purity | Guarantees no contamination; ideal for semiconductor, medical, and pharmaceutical uses. |

| Exceptional Chemical Resistance | Withstands aggressive acids, bases, and solvents; ideal for seals and linings. |

| Superior Low Friction | Self-lubricating; reduces wear in bearings and guides without contaminating products. |

| High-Temperature Stability | Maintains performance in demanding thermal environments. |

Need high-purity, high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact solution for your mission-critical application, guaranteeing the performance consistency and material integrity that only virgin PTFE can provide.

Contact KINTEK today to discuss your project requirements and experience the difference of working with a PTFE expert.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application