In safety-critical industries like food and pharmaceuticals, material choice is non-negotiable. PTFE envelope gaskets are exceptionally suitable for these applications because they provide a chemically inert, non-toxic, and non-stick surface that complies with strict regulatory standards like those from the FDA. This unique combination of properties ensures that the gasket will not contaminate the product, can be easily and thoroughly cleaned, and can withstand sterilization processes.

The suitability of PTFE envelope gaskets goes beyond simple compliance. It is the material's fundamental chemical inertness, combined with its operational benefits like cleanability and thermal stability, that makes it an essential component for ensuring both product purity and process hygiene.

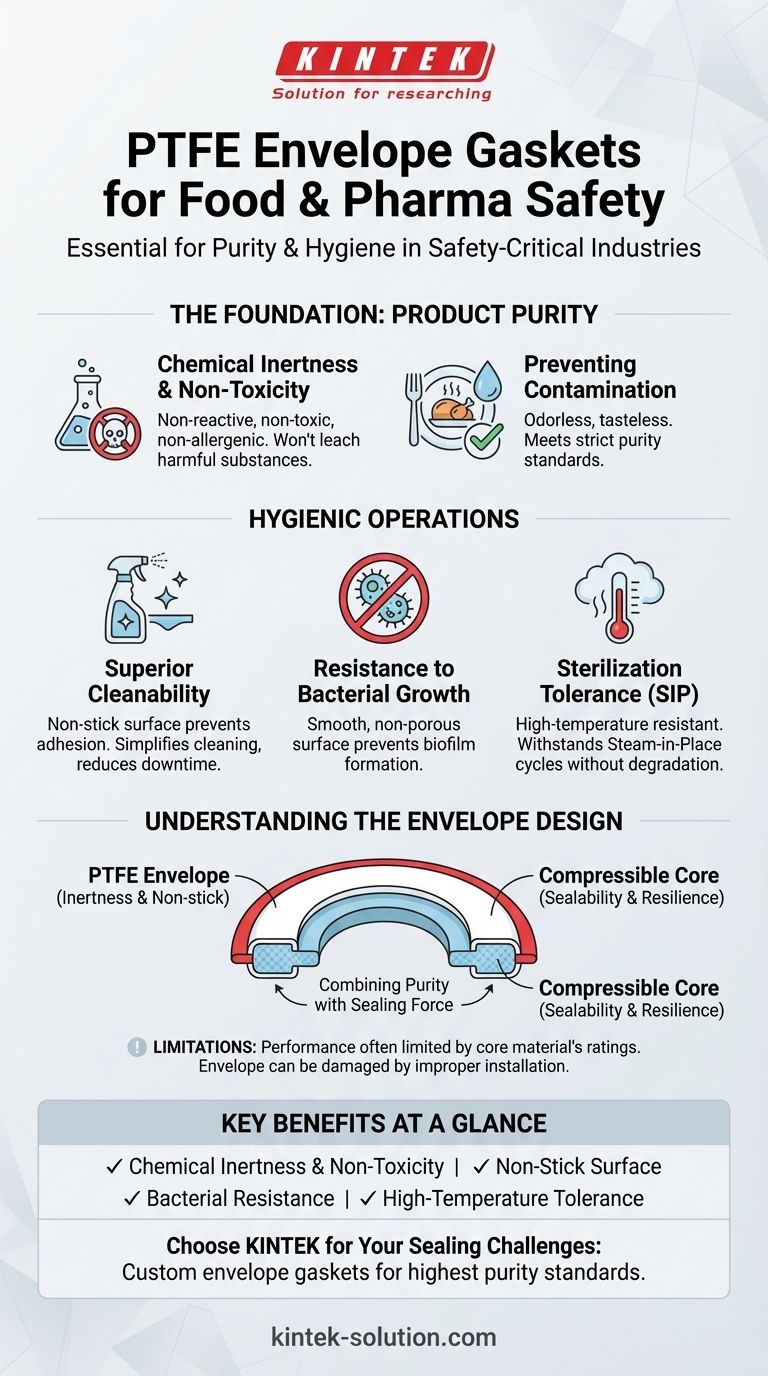

The Foundation: Ensuring Product Purity

In food and pharmaceutical processing, the primary goal is to protect the integrity and safety of the final product. The sealing material cannot, under any circumstances, compromise this.

Chemical Inertness and Non-Toxicity

PTFE is one of the most chemically inert polymers known. It does not react with the vast majority of chemicals, including aggressive cleaning agents, process fluids, or the final product itself.

Because of this inertness, it is non-toxic, non-allergenic, and will not leach harmful substances into the process stream. This ensures the product's composition remains unaltered and safe for consumption.

Preventing Contamination

A key requirement for any material in these industries is that it must be non-contaminating. PTFE is naturally odorless and tasteless, ensuring it imparts no unwanted characteristics to the product.

Its formulation meets strict purity standards, guaranteeing it is free of contaminants that could compromise a batch or violate regulatory requirements.

Designed for Hygienic Operations

Beyond just being safe, materials must also support the clean and sterile environment required in food and pharma facilities.

Superior Cleanability

PTFE has an extremely low coefficient of friction, creating a non-stick surface. This property is critical as it prevents process media—be it a food slurry or a pharmaceutical compound—from adhering to the gasket.

This non-stick nature drastically simplifies cleaning, reduces the risk of cross-contamination between batches, and minimizes downtime associated with manual scraping or intensive cleaning cycles.

Resistance to Bacterial Growth

The surface of PTFE is smooth and non-porous. This physical characteristic makes it very difficult for bacteria and other microbes to attach and form biofilms.

This inherent resistance to bacterial growth is a crucial element in maintaining a hygienic processing environment and complying with sanitary standards.

Tolerance for Sterilization

Many food and pharmaceutical processes rely on high-temperature sterilization methods, such as Steam-in-Place (SIP).

PTFE exhibits excellent high-temperature resistance, allowing it to maintain its structural integrity and sealing properties during these essential sterilization cycles without degrading, melting, or releasing fumes.

Understanding the Trade-offs: The "Envelope" Design

A "PTFE envelope" gasket is a composite seal. It is not made of solid PTFE, and understanding this construction is key to its proper application.

Combining Sealing Force with Purity

The design consists of a softer, more compressible core material (like a rubber or non-asbestos fiber) that is encapsulated within a thin "envelope" of PTFE.

This smart design leverages the best of both worlds: the compressibility and resilience of the core material to create a tight seal, and the chemical inertness and non-stick surface of the PTFE envelope to interface with the process media.

Limitations to Consider

The performance of an envelope gasket is often limited by its core material. While the PTFE envelope can handle extreme chemicals and high temperatures, the core material may have a lower temperature or pressure rating.

Furthermore, the PTFE envelope is relatively thin and can be damaged by improper flange alignment or over-torquing during installation. A compromised envelope negates all of the material's protective benefits.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your specific operational goals.

- If your primary focus is preventing product contamination: PTFE's validated chemical inertness and FDA compliance make it the definitive choice for direct product contact.

- If your primary focus is operational hygiene: The non-stick surface and resistance to aggressive cleaning agents reduce cleaning time and ensure consistent sanitary conditions.

- If your primary focus is sealing in high-pressure or high-temperature systems: You must verify that both the PTFE envelope and, critically, its inner core material are rated for your specific operating conditions.

Ultimately, choosing a PTFE envelope gasket is an investment in regulatory compliance, product integrity, and operational reliability.

Summary Table:

| Key Property | Benefit for Food & Pharma Applications |

|---|---|

| Chemical Inertness & Non-Toxicity | Prevents product contamination and ensures FDA compliance. |

| Non-Stick Surface | Simplifies cleaning, reduces cross-contamination risk. |

| Resistance to Bacterial Growth | Maintains a hygienic processing environment. |

| High-Temperature Resistance | Withstands Steam-in-Place (SIP) and other sterilization cycles. |

Ensure your process meets the highest standards of purity and hygiene. The right PTFE envelope gasket is critical for protecting your product and ensuring regulatory compliance in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom envelope gaskets. From prototypes to high-volume orders, our custom fabrication expertise ensures you get a seal perfectly tailored to your specific application requirements. Contact KINTEK today to discuss your sealing challenges and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why are PTFE extruded rods used in chemical processing equipment? For Superior Chemical Resistance and Purity

- What advancements are being made in recycling Teflon scrap? From Micronization to Upcycling

- What are the challenges and recommendations for machining Teflon? Master Precision PTFE Fabrication

- How does PTFE impregnated with silicone oil improve gland packing performance? Enhance Sealing with Low Friction

- Why are PTFE-free bushings considered environmentally friendly? Reduce PFAS Risk & Enhance Sustainability

- Which industries commonly use PTFE cryogenic seals? Essential for Aerospace, Oil & Gas, and Pharma

- What is the hardness rating of Teflon balls? Understanding PTFE's Softness for Optimal Use

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions