At its core, expanded PTFE (ePTFE) is a highly advanced form of Polytetrafluoroethylene (PTFE). It begins as 100% virgin PTFE but is mechanically transformed into a unique microporous material with a strong, multi-directional fibrous structure. This process gives ePTFE remarkable properties, making it far more versatile than standard PTFE for certain demanding applications like sealing and insulation.

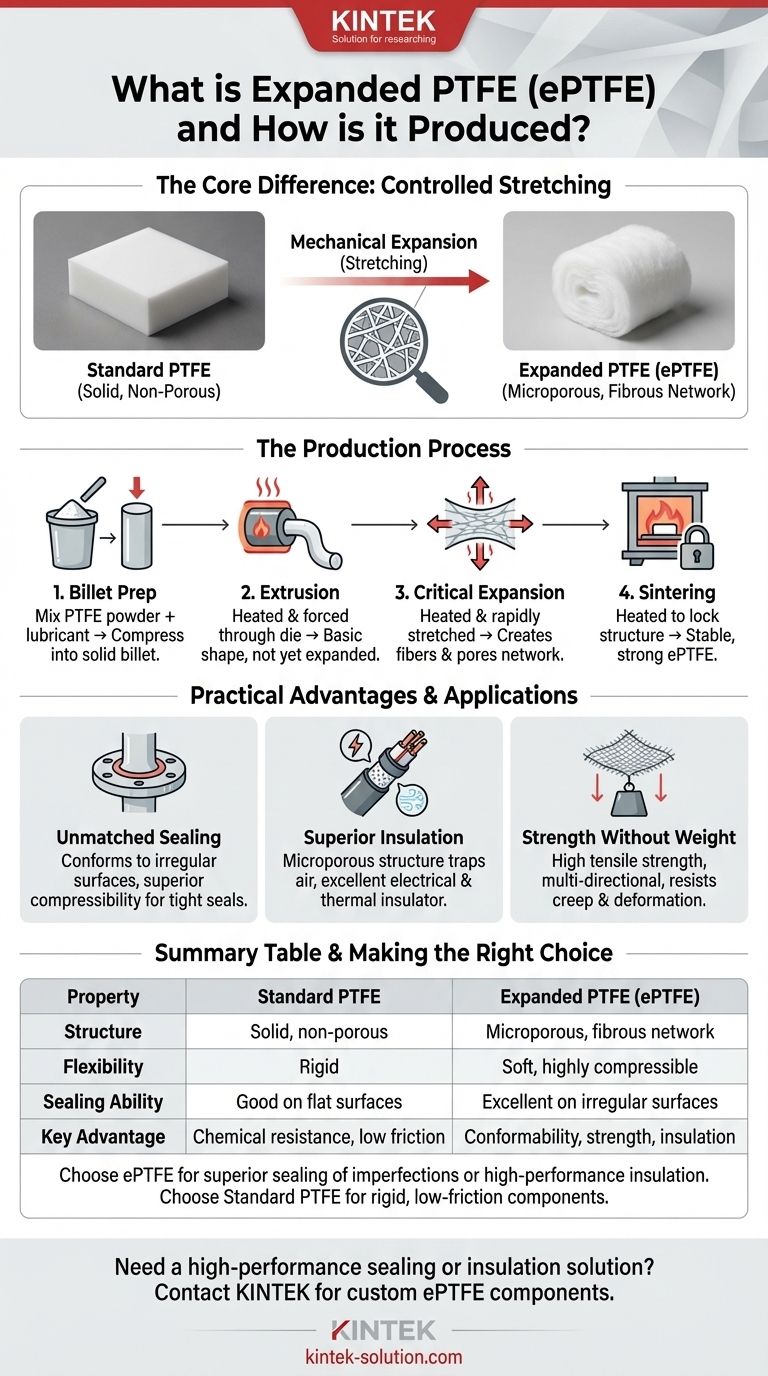

The essential difference between PTFE and ePTFE lies in a manufacturing process of controlled stretching. This mechanical expansion creates a microscopic web of fibers and pores, transforming a rigid plastic into a soft, strong, and highly compressible material.

What Defines ePTFE?

ePTFE retains all the desirable properties of standard PTFE, such as excellent chemical resistance and a wide temperature tolerance. However, the expansion process introduces new physical characteristics that set it apart.

The Unique Microporous Structure

The defining feature of ePTFE is its structure of interconnected microfibers and pores. This highly fibrous network gives the material a texture often compared to a dense marshmallow.

This structure is not a chemical change but a physical one. It makes the material simultaneously strong, flexible, and lightweight.

Enhanced Physical Properties

While standard PTFE is relatively rigid, ePTFE is exceptionally soft and conformable. This allows it to adapt perfectly to irregular surfaces, which is critical for sealing applications.

Its fibrous nature provides multi-directional strength, meaning it resists tearing or deformation even when compressed or stretched.

The ePTFE Production Process Explained

The creation of ePTFE is a multi-step process that hinges on the precise mechanical manipulation of PTFE resin. It's this physical transformation, not a chemical reaction, that creates the final material.

Step 1: Preparing the PTFE Billet

The process begins by mixing a special PTFE fine powder resin with a lubricant or processing aid. This mixture is then compressed into a solid cylindrical preform, often called a billet.

Step 2: Extrusion

The billet is heated and forced through a die in a process called extrusion. This shapes the PTFE into a basic form, like a tape or a tube, but it does not yet have its expanded properties.

Step 3: The Critical Expansion Stage

This is the key step that creates ePTFE. The extruded material is heated to a high temperature (below its melting point) and then stretched rapidly and precisely.

This stretching can occur in one direction (uniaxial) or multiple directions (longitudinal and transverse). The mechanical force pulls the PTFE's molecular structure apart, creating the distinctive network of fibers and pores.

Step 4: Sintering to Lock the Structure

After expansion, the material is heated to an even higher temperature in a process called sintering. This locks the fibrous, porous structure into place, making the material stable and strong.

The result is a material that is still 100% PTFE but with a completely new and highly functional physical form.

Understanding the Practical Advantages

The transformation from solid PTFE to microporous ePTFE directly translates into superior performance in specific roles, particularly where a perfect seal is non-negotiable.

Unmatched Sealing Capability

The soft, compressible nature of ePTFE allows it to create an extremely tight seal, even on damaged or uneven flange surfaces. It fills in microscopic imperfections where a rigid gasket would fail.

This makes ePTFE gaskets ideal for applications with fluctuating pressure and temperature conditions, as the material can adapt to maintain the seal.

Superior Insulation

The microporous structure traps air, making ePTFE an excellent electrical and thermal insulator. This property is leveraged in high-performance cable wrapping and other sensitive electrical systems.

Strength Without the Weight

Despite being porous and lightweight, the interwoven fibrous structure gives ePTFE impressive tensile strength. It can withstand significant force without breaking, a property known as "creep resistance" in sealing applications.

Making the Right Choice for Your Application

Understanding the fundamental difference between standard PTFE and ePTFE is crucial for selecting the correct material for your needs.

- If your primary focus is sealing irregular or damaged surfaces: Choose ePTFE for its superior compressibility and ability to conform to imperfections.

- If your primary focus is high-performance electrical insulation: ePTFE's microporous structure provides an exceptional dielectric medium for wrapping cables.

- If your application requires a rigid, low-friction component: Standard, non-expanded PTFE remains the superior choice for bearings, bushings, or structural parts.

Ultimately, the expansion process unlocks the hidden potential within PTFE, transforming it into a high-performance material for solving critical engineering challenges.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid, non-porous | Microporous, fibrous network |

| Flexibility | Rigid | Soft, highly compressible |

| Sealing Ability | Good on flat surfaces | Excellent on irregular surfaces |

| Key Advantage | Chemical resistance, low friction | Conformability, multi-directional strength, superior insulation |

Need a high-performance sealing or insulation solution?

At KINTEK, we specialize in precision manufacturing of custom ePTFE components. Our expertise in PTFE fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your exact requirements in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today to discuss how ePTFE can solve your critical engineering challenges.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some examples of ePTFE applications in aerospace and automotive industries? Critical Components for Extreme Environments

- What are the advantages of using PTFE bushes? Low-Friction, Chemical-Resistant Performance

- What is the primary function of PTFE pneumatic valves? Control Corrosive Media with Unmatched Reliability

- What are the limitations of Teflon encapsulated O-rings in terms of chemical resistance? Key Weaknesses to Avoid Seal Failure

- What are the best practices for drilling and tapping PTFE? Achieve Clean, Precise Machining

- What types of Teflon backup rings are available and their uses? Ensure Sealing Integrity in High-Pressure Systems

- What is the pH range that PTFE Enveloped Gaskets can handle? Achieve Universal Chemical Resistance

- What advantages do PTFE balls offer over traditional materials? Superior Chemical Resistance & Non-Stick Performance