In short, CNC machining is the superior method for PTFE components because it provides the precision and control necessary to overcome the material's inherent challenges. This results in high-quality parts with minimal error, reduced material waste, and the ability to produce highly intricate designs that would be impossible with manual methods.

The core advantage of using CNC for PTFE isn't just about speed or automation; it's about gaining precise control over a uniquely difficult material. CNC transforms PTFE's liabilities, like thermal expansion and softness, into manageable variables, ensuring the final component meets exact specifications.

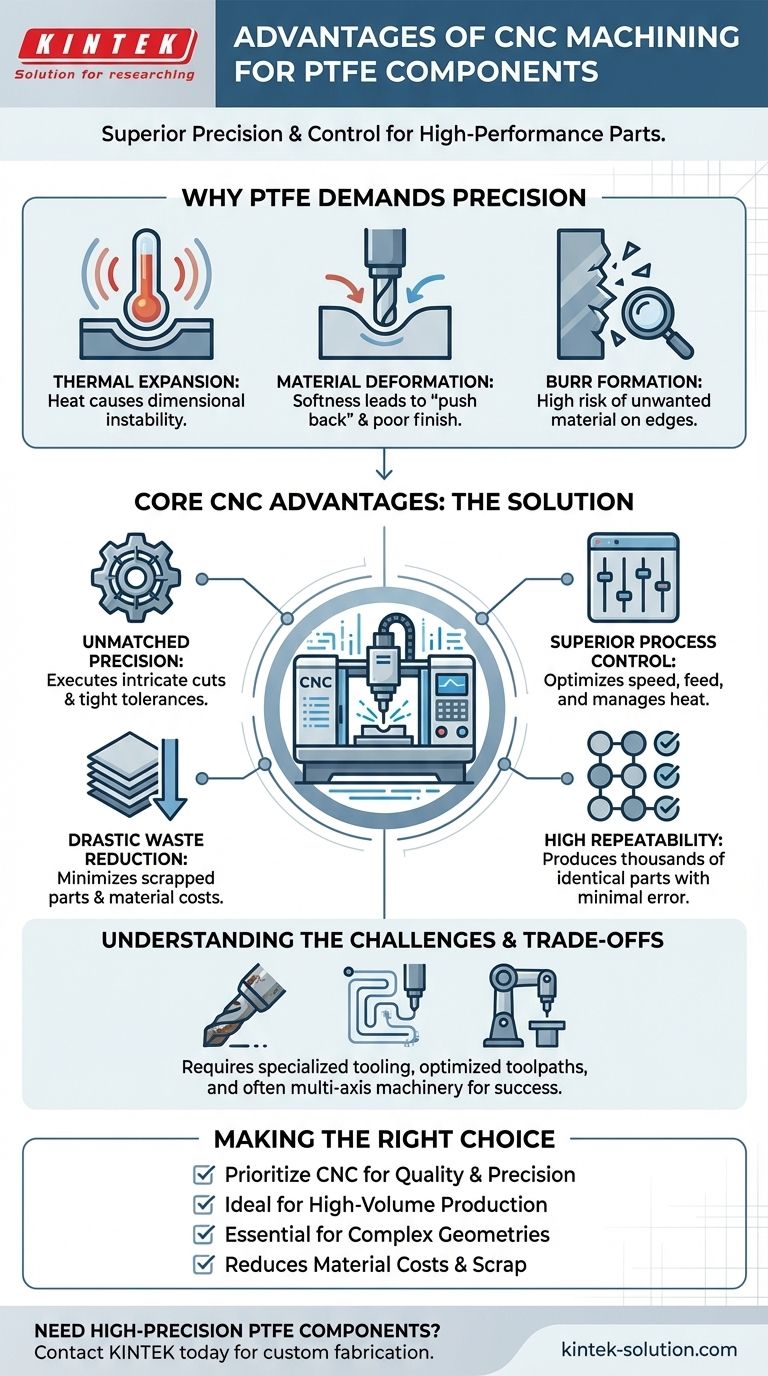

Why PTFE Demands Precision Machining

Polytetrafluoroethylene (PTFE) is a high-performance polymer prized for its properties, but these same properties make it notoriously difficult to machine accurately. Understanding these challenges is key to appreciating why CNC is not just a benefit, but often a necessity.

The Challenge of Thermal Expansion

PTFE has a very high rate of thermal expansion. The heat generated during machining can cause the material to expand, leading to inaccurate cuts and dimensional instability once it cools.

The Tendency to Deform and "Push Back"

As a soft material, PTFE can easily deform under the pressure of a cutting tool rather than cutting cleanly. This can lead to poor surface finishes and parts that are out of tolerance.

The Constant Risk of Burr Formation

The softness of PTFE also means it is highly prone to burr formation—small, unwanted pieces of material left attached to the edge of the part. Removing these burrs without damaging the component requires significant care and often secondary finishing processes.

The Core Advantages of CNC for PTFE

CNC (Computer Numerical Control) machining directly addresses the inherent difficulties of working with PTFE by replacing manual inconsistency with programmable, repeatable precision.

Unmatched Precision for Complex Geometries

CNC machines operate from a digital design file, enabling them to execute highly intricate cuts and complex shapes with extreme accuracy. This is critical for components like seals, insulators, and medical devices where tight tolerances are non-negotiable.

Superior Control Over Machining Parameters

A CNC program allows for the precise optimization of cutting speeds, feed rates, and toolpaths. This control is essential for managing heat generation, minimizing tool pressure, and preventing the material deformation and thermal expansion that plague manual PTFE machining.

Drastic Reduction in Material Waste

By optimizing the toolpath and ensuring high accuracy on the first pass, CNC machining significantly minimizes scrapped parts and wasted material. This is a crucial economic advantage, especially when working with high-cost performance plastics.

Repeatability and Reduced Error Rates

Once a program is perfected, a CNC machine can produce thousands of identical parts with virtually no deviation. This level of consistency eliminates the human error inherent in manual processes, ensuring every component meets the required quality standard.

Understanding the Trade-offs and Challenges

While highly advantageous, CNC machining PTFE is not without its own set of considerations. Success requires a sophisticated approach to the process.

The Importance of Tool Selection and Wear

PTFE can be abrasive to cutting tools, causing them to wear down quickly. Using sharp, correctly shaped tools made from appropriate materials is critical to achieving a clean cut and preventing burr formation. Continuous monitoring for tool erosion is necessary.

The Need for Optimized Toolpaths

Advanced programming is often required to create toolpaths that minimize heat and cutting pressure. Strategies like climb milling and using specific entry/exit points for the cutter are essential for maintaining surface quality.

The Role of Advanced Machinery

For the most complex PTFE parts, standard 3-axis machines may not be sufficient. Multi-axis CNC machines are often necessary to achieve the precise angles and smooth finishes required, allowing the tool to approach the workpiece from multiple directions.

Making the Right Choice for Your Component

Ultimately, turning to CNC machining for PTFE is a decision to prioritize quality, precision, and repeatability over the unpredictability of manual methods.

- If your primary focus is high-volume production with tight tolerances: CNC machining is the only viable path to ensure every part is identical and meets specification.

- If your primary focus is creating intricate or complex geometries: The digital precision of multi-axis CNC is necessary to produce features that are physically impossible to create manually.

- If your primary focus is minimizing material costs and scrap rates: The optimized, repeatable process of CNC significantly reduces waste compared to manual trial and error.

By leveraging the precise control of CNC, you can reliably transform this challenging polymer into high-performance components that meet the most demanding requirements.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Precision | Enables complex geometries and tight tolerances impossible with manual methods. |

| Superior Process Control | Manages heat and tool pressure to prevent deformation and ensure accuracy. |

| Reduced Material Waste | Optimized toolpaths minimize scrap, lowering costs for high-performance plastics. |

| High Repeatability | Produces thousands of identical parts with minimal error, ensuring quality. |

Need high-precision PTFE components for your application?

KINTEK specializes in CNC machining PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures your parts overcome PTFE's challenges and meet exact specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability