In short, PTFE seat butterfly valves are the premier choice for environments defined by aggressive chemicals, high-purity requirements, and a wide range of temperatures. Their unique properties make them indispensable in demanding sectors like chemical processing, pharmaceuticals, and food and beverage production where media purity and corrosion resistance are non-negotiable.

The core value of a PTFE seated valve lies in its chemical inertness. This makes it an ideal solution for corrosive and high-purity applications, but this same material softness creates a critical limitation: it is not suitable for services containing abrasive particles.

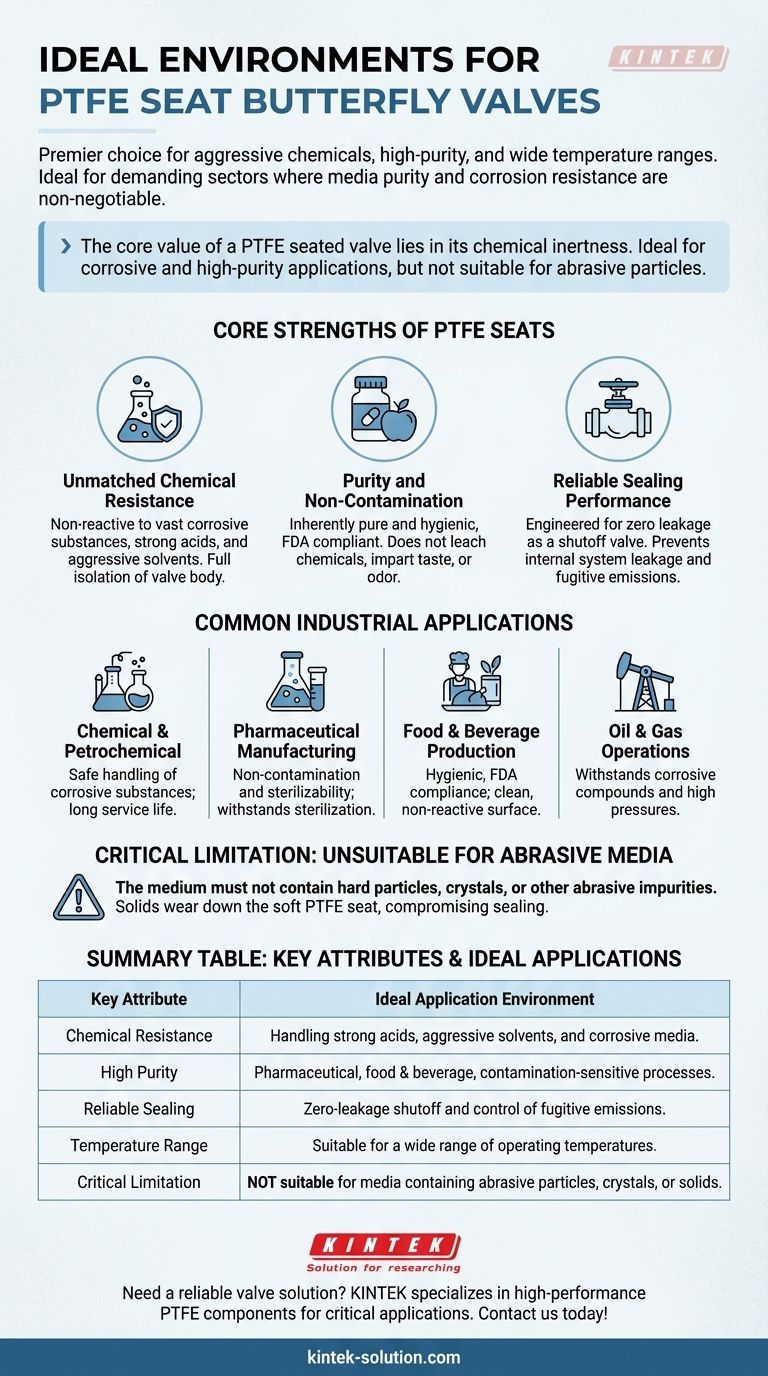

The Core Strengths of PTFE Seats

To understand where these valves fit, we must first understand the material properties of Polytetrafluoroethylene (PTFE). Its unique molecular structure is the source of its primary advantages in industrial valve applications.

Unmatched Chemical Resistance

PTFE is almost universally non-reactive. It can safely handle a vast array of corrosive substances, from strong acids to aggressive solvents, without degrading.

This is because the valve body and other internal components do not come into direct contact with the fluid medium, which is fully isolated by the PTFE liner.

Purity and Non-Contamination

In industries like pharmaceuticals or food and beverage, preventing media contamination is critical. PTFE is an inherently pure and hygienic material, often compliant with FDA standards.

Because it does not leach chemicals or impart taste or odor, it ensures the integrity of the final product.

Reliable Sealing Performance

PTFE seats are designed to provide excellent and reliable sealing. When used as a shutoff valve, they are engineered for zero leakage.

This capability is crucial for both preventing internal system leakage and stopping fugitive emissions from escaping into the atmosphere.

Common Industrial Applications

The combination of chemical inertness, purity, and reliable sealing makes PTFE seat butterfly valves a standard in several key industries.

Chemical and Petrochemical Processing

These valves are widely used for safely handling corrosive substances. Their durability in harsh chemical environments ensures both operational safety and a long service life.

Pharmaceutical Manufacturing

The dual requirements of non-contamination and sterilizability make PTFE an ideal choice. It can withstand sterilization processes while ensuring the handled media remains pure.

Food and Beverage Production

Due to its hygienic properties and FDA compliance, PTFE is a trusted material for food-grade applications. It provides a clean, non-reactive surface for processing sensitive products.

Oil and Gas Operations

In the oil and gas sector, these valves are valued for their ability to withstand the corrosive compounds and high pressures often found in processing streams.

Understanding the Trade-offs and Limitations

No single valve solution is perfect for every scenario. While PTFE offers significant advantages, its limitations are just as important to understand to prevent misapplication and failure.

Unsuitability for Abrasive Media

This is the most critical limitation of PTFE seats. The medium must not contain hard particles, crystals, or other abrasive impurities.

These solids will quickly wear down the soft PTFE seat lining during valve operation. This damage compromises the valve's sealing performance, leading to leaks and premature failure.

Installation Sensitivity

Due to their design, achieving optimal performance requires proper installation. Care must be taken to ensure correct pipe alignment and to follow precise bolting and torque procedures.

Improper installation can damage the seat and prevent it from creating the reliable, zero-leakage seal it was designed for.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your operational goals. A PTFE seat butterfly valve is an excellent technical solution, but only when applied in the right context.

- If your primary focus is handling corrosive chemicals or high-purity media: The inert nature of PTFE makes it the definitive and safest choice for your application.

- If your primary focus is on an extremely tight, zero-leakage shutoff: A properly installed PTFE seat valve provides one of the most reliable soft-seat seals available.

- If your primary focus is controlling media with hard particles or abrasives: You must select a different valve type, such as a metal-seated butterfly valve, to avoid rapid seat failure.

Ultimately, understanding both the strengths and weaknesses of PTFE is key to leveraging its superior performance in the environments where it truly excels.

Summary Table:

| Key Attribute | Ideal Application Environment |

|---|---|

| Chemical Resistance | Handling strong acids, aggressive solvents, and corrosive media. |

| High Purity | Pharmaceutical manufacturing, food & beverage production, and other contamination-sensitive processes. |

| Reliable Sealing | Applications demanding zero-leakage shutoff and control of fugitive emissions. |

| Temperature Range | Suitable for a wide range of operating temperatures. |

| Critical Limitation | NOT suitable for media containing abrasive particles, crystals, or solids. |

Need a reliable valve solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals and liners for critical applications in the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your valves and systems meet the highest standards for purity, chemical resistance, and sealing performance.

Let us help you select or fabricate the perfect component for your needs, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability