The primary semi-finished products available in PTFE are rods, tubes, sheets (also called plates), and films. These basic shapes are created through a compression and heating process and serve as the foundational stock material from which more complex, finished components are manufactured.

The key to understanding PTFE availability is recognizing that its unique properties dictate a manufacturing process limited to creating simple, dense shapes. These semi-finished forms—rods, tubes, and sheets—are the essential building blocks that are then machined into highly specific final parts.

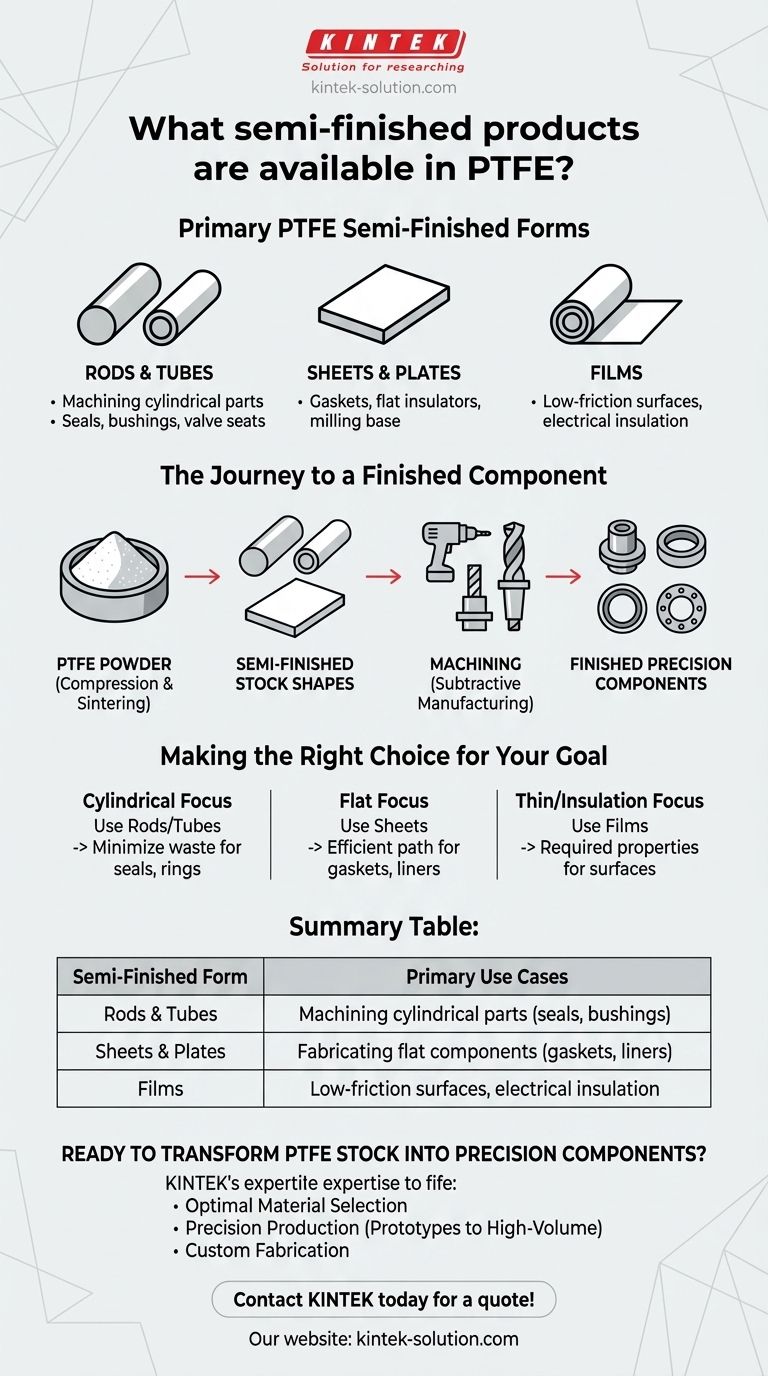

Understanding the Primary PTFE Forms

Polytetrafluoroethylene (PTFE) is not melted and injection molded like many common plastics. Instead, it is compressed from a powder and sintered (a high-heat fusion process), which results in the production of simple, solid stock shapes.

Rods and Tubes

PTFE rods are solid cylinders, while tubes are hollow cylinders. They are among the most common semi-finished forms available.

These shapes are the ideal starting point for creating any finished part that is fundamentally cylindrical through a machining process.

Sheets and Plates

PTFE sheets and plates are large, flat stock materials. They provide a versatile base for creating a wide range of components.

This form is typically used for cutting gaskets, fabricating flat insulators, or as a starting block for milling more complex, non-cylindrical parts.

Films

PTFE film is an extremely thin sheet of material, often used for applications requiring a low-friction surface or excellent electrical insulation. It can be manufactured as a standalone product or used as a liner.

The Journey to a Finished Component

The transition from a simple block of PTFE to a high-performance part like a valve seat involves secondary manufacturing processes, primarily machining.

The Role of Machining

Because PTFE cannot be easily molded into complex geometries, the vast majority of finished parts are created by cutting, drilling, and milling semi-finished stock shapes.

This subtractive manufacturing process allows for the creation of intricate designs with tight tolerances from the simple, standardized forms.

From Stock Shape to Final Part

The semi-finished product is chosen based on which form will produce the final part with the least amount of material waste and machining time.

For example, finished components like seals, bushings, rings, and insulators are almost always machined from rod or tube stock. A ball valve seat is a classic example of a part precisely machined from a PTFE rod.

Making the Right Choice for Your Goal

Selecting the correct semi-finished form is the first step in efficient and cost-effective component manufacturing.

- If your primary focus is creating cylindrical parts (seals, rings, bushings): Sourcing PTFE rods or tubes will minimize machining time and material waste.

- If your primary focus is producing flat components (gaskets, liners, plates): Starting with PTFE sheets is the most direct and efficient path.

- If your primary focus is electrical insulation or low-friction surfaces: PTFE films provide the necessary thinness and properties required for these applications.

Choosing the right initial form is critical to optimizing the production of your final PTFE component.

Summary Table:

| Semi-Finished PTFE Form | Primary Use Cases |

|---|---|

| Rods & Tubes | Machining cylindrical parts like seals, bushings, and valve seats. |

| Sheets & Plates | Fabricating flat components like gaskets, liners, and insulators. |

| Films | Applications requiring thin, low-friction surfaces or electrical insulation. |

Ready to Transform PTFE Stock into Precision Components?

KINTEK specializes in manufacturing high-quality PTFE components from these essential semi-finished forms. We serve the semiconductor, medical, laboratory, and industrial sectors by machining rods, tubes, and sheets into custom seals, liners, labware, and other critical parts.

Our expertise ensures:

- Optimal Material Selection: We help you choose the right PTFE form to minimize waste and machining time.

- Precision Production: From prototypes to high-volume orders, we deliver components with exacting tolerances.

- Custom Fabrication: We transform simple stock into complex, high-performance parts tailored to your application.

Let's discuss your project and find the most efficient path from raw material to finished part.

Contact KINTEK today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is resistance to chemical and physical corrosion important for PTFE gasket raw materials? Ensure Long-Term Sealing Reliability

- What is creep in PTFE gasket sheets and how can it be mitigated? Prevent Seal Failure and Leaks

- What is a PTFE sliding bearing pad and where is it used? Essential for Structures & Heavy Equipment

- What are the advantages of Teflon bushes' low friction? Achieve Maintenance-Free, Long-Lasting Performance

- What are the advantages of unreinforced PTFE laminates? Achieve Ultimate Signal Integrity for High-Frequency Designs

- What are the operational temperature limits for PTFE-lined diaphragm valves? Understanding the Full System Range

- What are the tolerances for PTFE balls? Achieve Precision in Your Application

- How are PTFE O-ring seals used in the automotive industry? Critical Sealing Solutions for High-Performance Vehicles