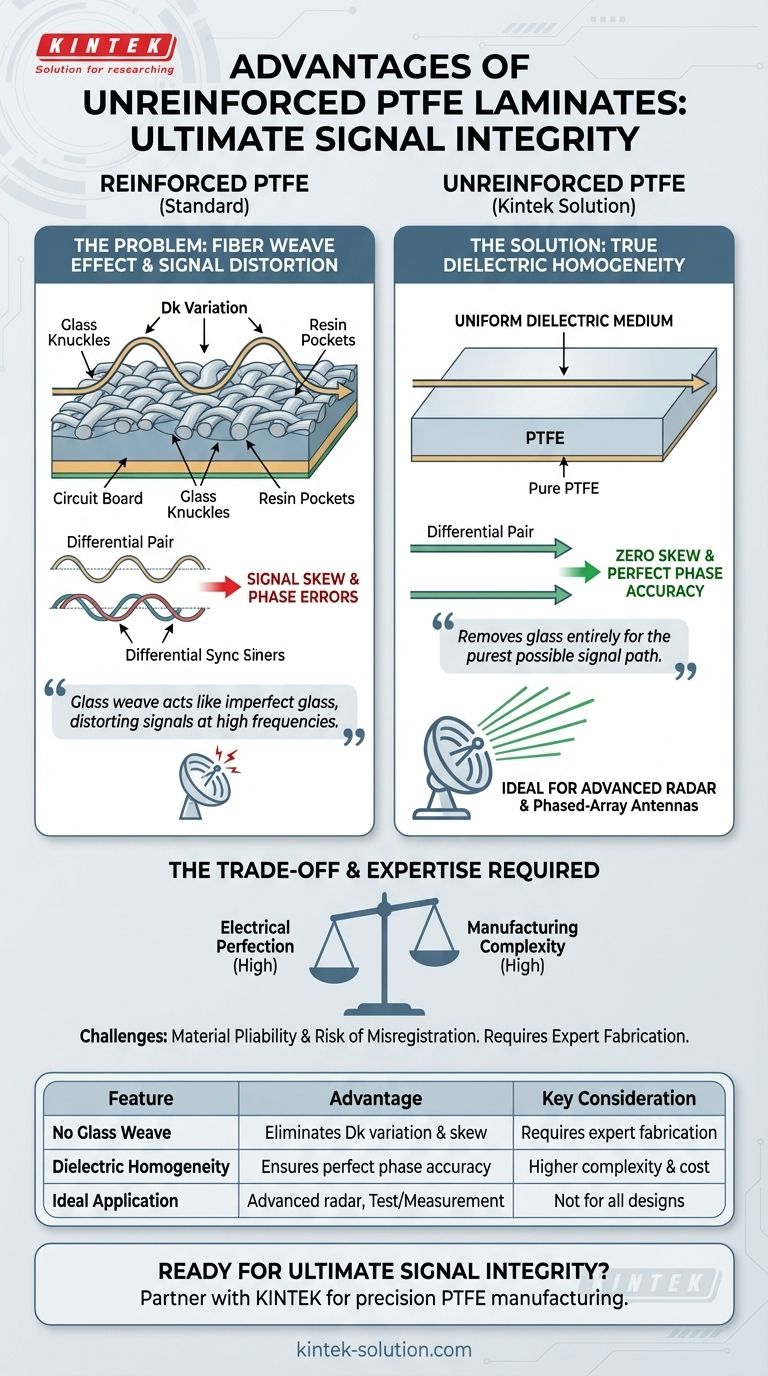

The primary advantage of unreinforced PTFE laminates is their complete elimination of signal distortion caused by fiber weave effects. By removing the woven glass fabric found in standard laminates, these materials provide a perfectly uniform dielectric medium, which is critical for maintaining signal integrity and phase accuracy in the most demanding high-frequency applications like advanced radar systems.

At millimeter-wave frequencies, the glass weave in conventional circuit board materials can distort signals, much like looking through imperfect glass. Unreinforced PTFE solves this by removing the glass entirely, offering the purest possible signal path at the cost of significant manufacturing complexity.

The Core Problem: Why Fiber Weave Degrades Signals

In high-frequency electronics, the consistency of the circuit board material is as important as the circuit design itself. Standard laminates embed a woven glass fabric within a resin system (like PTFE) for structural rigidity, but this creates a hidden problem.

Understanding Dielectric Constant (Dk) Variation

The glass fibers and the surrounding PTFE resin have different dielectric constants (Dk). This means that from the signal's perspective, the path is not uniform.

As a trace runs across the board, it passes over areas with dense glass knuckles and areas with mostly resin. This constant change in the underlying material creates localized Dk variations.

The Impact on Signal Skew

This Dk inconsistency causes different parts of a signal's electromagnetic wave to travel at slightly different speeds.

In differential pairs, where two traces must remain perfectly synchronized, this effect causes signal skew—one signal arrives slightly before the other. This timing error distorts the overall signal and degrades performance.

The Challenge for Phased-Array Antennas

This problem is especially damaging for systems like phased-array antennas. These devices rely on precise timing and phase relationships between dozens or hundreds of elements to steer a radar beam. Fiber weave-induced skew introduces phase errors that can disrupt the entire system's accuracy.

How Unreinforced PTFE Provides the Solution

Unreinforced PTFE laminates address this fundamental problem by removing the source of the inconsistency: the glass weave.

Achieving True Dielectric Homogeneity

By consisting of only PTFE, often with ceramic particle fillers to tailor its properties, the material is dielectrically homogeneous.

The Dk value is consistent at every point along a signal trace. There are no "pockets" of high or low Dk to interfere with the signal's propagation.

Eliminating Skew and Phase Errors

This uniformity completely eliminates fiber weave skew. Signals travel at a constant, predictable velocity, ensuring that differential pairs remain synchronized and phase relationships in complex circuits are perfectly maintained.

This makes unreinforced PTFE the ideal substrate for applications where phase accuracy is the highest priority.

Understanding the Trade-offs: Manufacturing and Rigidity

The electrical perfection of unreinforced PTFE comes at a significant mechanical cost. Removing the glass reinforcement makes the material extremely pliable and dimensionally unstable before and during processing.

The Challenge of Pliability

Unreinforced PTFE is very soft and lacks the rigidity of its reinforced counterparts. This makes it difficult to handle during fabrication without introducing stress or distortion.

Risk of Layer-to-Layer Misregistration

In multilayer circuit boards, this lack of rigidity can lead to layers shifting during the lamination process. This misregistration can cause critical alignment features, like vias and pads, to be off-center.

The Need for an Expert Fabricator

These handling challenges mean that successful fabrication requires specialized equipment and deep process expertise. Misalignment of drill holes or pads can create impedance discontinuities, causing return loss and negating the material's electrical benefits. Only an experienced fabricator should be trusted with these materials.

Making the Right Choice for Your Design

Selecting a laminate requires balancing electrical performance against manufacturability and cost. Unreinforced PTFE represents one end of that spectrum—maximum performance for maximum complexity.

- If your primary focus is ultimate phase accuracy (e.g., advanced millimeter-wave radar, test/measurement fixtures): Unreinforced PTFE is the superior choice, provided you partner with a capable fabricator.

- If your primary focus is balancing performance with manufacturability: Consider laminates with spread-glass reinforcement, which flattens the weave to minimize (but not eliminate) skew without the extreme handling challenges.

- If your primary focus is general high-frequency performance without strict phase constraints: Standard reinforced PTFE offers a robust and cost-effective solution for a wide range of applications.

Choosing the right laminate is about matching the material's electrical purity to your application's sensitivity.

Summary Table:

| Feature | Advantage | Key Consideration |

|---|---|---|

| No Glass Weave | Eliminates dielectric constant (Dk) variation and signal skew | Requires expert fabrication due to material pliability |

| Dielectric Homogeneity | Ensures perfect phase accuracy for phased-array antennas | Higher cost and manufacturing complexity |

| Ideal Application | Advanced radar, test/measurement fixtures | Not necessary for all high-frequency designs |

Ready to achieve ultimate signal integrity in your high-frequency designs?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom laminates for the most demanding semiconductor, medical, and laboratory applications. Our expertise in handling advanced materials like unreinforced PTFE ensures your designs are fabricated to the highest standards, preserving signal integrity from prototype to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can solve your most critical design challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials