The fundamental advantage of Teflon bushes' low friction is their ability to operate smoothly and reliably without any external lubrication. This self-lubricating property is the source of its most significant benefits: drastically reduced wear on moving parts, lower maintenance requirements, and extended equipment lifespan.

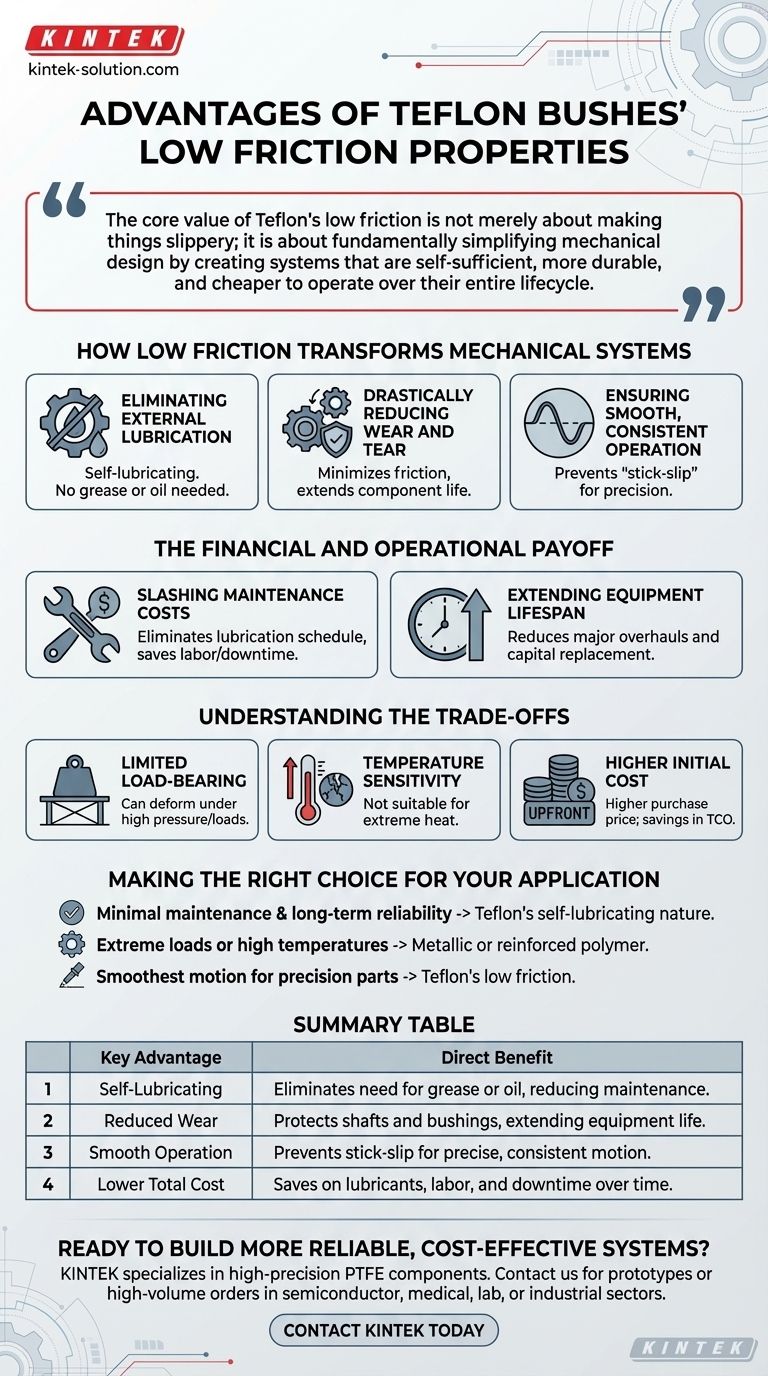

The core value of Teflon's low friction is not merely about making things slippery; it is about fundamentally simplifying mechanical design by creating systems that are self-sufficient, more durable, and cheaper to operate over their entire lifecycle.

How Low Friction Transforms Mechanical Systems

The exceptionally low coefficient of friction in Teflon (PTFE) is not just a minor improvement; it changes the entire dynamic between moving components.

Eliminating External Lubrication

Teflon is inherently self-lubricating. Its surface allows parts to glide over one another with minimal resistance.

This completely removes the need for applying grease, oil, or other lubricants that are essential for most metal or plastic bushings.

Drastically Reducing Wear and Tear

Friction is a primary cause of mechanical wear. By minimizing this force, Teflon bushes protect both themselves and the shafts they support.

This direct reduction in abrasion means components last significantly longer, maintaining their critical tolerances and performance over time.

Ensuring Smooth, Consistent Operation

The low friction prevents the "stick-slip" phenomenon, where parts can momentarily seize and release, causing jerky or inconsistent movement.

This makes Teflon bushings ideal for applications requiring precision and smoothness, from delicate instruments to high-speed rotating machinery.

The Financial and Operational Payoff

The technical benefits of low friction translate directly into measurable savings in cost, labor, and operational uptime.

Slashing Maintenance Costs

Without the need for a regular lubrication schedule, you eliminate the associated costs of lubricants, labor, and planned downtime.

This is especially valuable in continuous material handling or manufacturing environments where every minute of operation counts.

Extending Equipment Lifespan

By acting as a protective, low-wear interface, Teflon bushes extend the life of more expensive components like shafts and housings.

This reduces the frequency of major overhauls and capital equipment replacement, leading to significant long-term cost savings.

Understanding the Trade-offs

While its low friction is a powerful advantage, Teflon is not the universal solution for every application. Objectivity requires acknowledging its limitations.

Limited Load-Bearing Capacity

Standard Teflon is a relatively soft material. In applications with extremely high pressure or heavy loads, it can deform or "creep" over time. Reinforced or filled PTFE variants are often required to handle these conditions.

Temperature Sensitivity

While Teflon has a wide operating temperature range, it is not suitable for high-temperature environments where metallic bushings would excel. Excessive heat can cause it to lose its structural integrity.

Higher Initial Cost

Compared to simple nylon or some bronze bushings, Teflon components can have a higher upfront purchase price. The financial benefit is realized through the total cost of ownership, not the initial procurement.

Making the Right Choice for Your Application

Selecting the right bushing material depends entirely on the primary goal of your design.

- If your primary focus is minimal maintenance and long-term reliability: Teflon's self-lubricating nature makes it the superior choice for "fit and forget" systems.

- If your primary focus is handling extreme physical loads or high temperatures: A metallic bushing or a specialized, reinforced polymer may be a more appropriate and durable solution.

- If your primary focus is achieving the smoothest motion for precision parts: Teflon's exceptionally low coefficient of friction provides unparalleled performance.

Ultimately, leveraging Teflon's low friction is a strategic decision to build more reliable and cost-effective systems from the inside out.

Summary Table:

| Key Advantage | Direct Benefit |

|---|---|

| Self-Lubricating | Eliminates need for grease or oil, reducing maintenance. |

| Reduced Wear | Protects shafts and bushings, extending equipment life. |

| Smooth Operation | Prevents stick-slip for precise, consistent motion. |

| Lower Total Cost | Saves on lubricants, labor, and downtime over time. |

Ready to build more reliable, cost-effective systems?

KINTEK specializes in manufacturing high-precision PTFE components, including custom Teflon bushes, seals, liners, and labware. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get the right self-lubricating solution for your application.

Contact KINTEK today to discuss how our PTFE components can enhance your design's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments