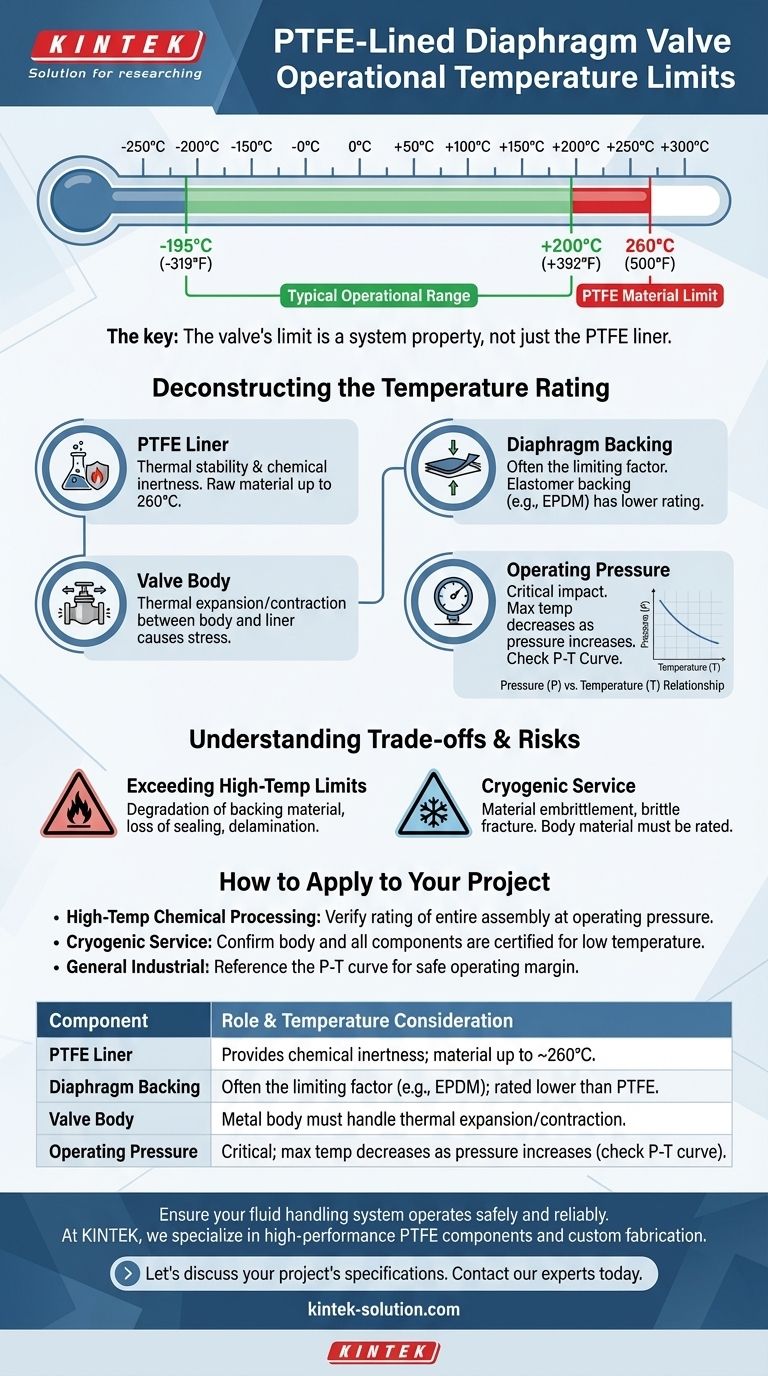

In short, the operational temperature range for a PTFE-lined diaphragm valve is remarkably wide. A typical valve can operate from cryogenic temperatures as low as -195°C (-319°F) up to a high of 200°C (392°F). While the pure PTFE material itself can withstand temperatures up to 260°C (500°F), the valve's overall rating is determined by the entire assembly.

The key is to understand that a valve's temperature limit is not just defined by its PTFE liner. It is a system property dictated by the interplay between the liner, the diaphragm's backing material, the valve body, and the operating pressure.

Deconstructing the Temperature Rating

To properly select a valve, you must look beyond the single specification for PTFE and consider how each component contributes to the valve's overall performance envelope.

The Role of the PTFE Liner

Polytetrafluoroethylene (PTFE) is chosen for its exceptional properties. Its thermal stability allows it to maintain structural integrity at high temperatures, while its chemical inertness makes it resistant to nearly all corrosive media. This is the component that gives the valve its impressive high-temperature potential, with the raw material often rated up to 260°C.

Why the Valve Rating is Often Lower

The 200°C figure is a more realistic operational limit for the complete valve assembly. The diaphragm is often a composite structure, featuring a PTFE wetted side bonded to a more flexible elastomer backing (like EPDM or rubber) for support and actuation. This backing material typically has a lower maximum temperature rating than PTFE and becomes the limiting factor.

The Influence of the Valve Body

The valve's body material—such as ductile iron or stainless steel—must also be considered. At extreme temperatures, both high and low, thermal expansion and contraction rates between the metal body and the PTFE liner can create stress. This can impact sealing performance and the long-term integrity of the liner.

The Critical Impact of Pressure

Temperature and pressure are inseparable. A valve's maximum allowable temperature decreases as the internal pressure increases. Manufacturers provide a Pressure-Temperature (P-T) curve for each valve model. This chart is the definitive guide, showing the safe operating envelope for the valve assembly. Ignoring the P-T curve is a common and critical mistake.

Understanding the Trade-offs and Risks

Operating a valve near its temperature limits requires careful consideration of the potential failure modes.

Exceeding High-Temperature Limits

Pushing the valve beyond its rated temperature, even for short periods, can have serious consequences. You risk the degradation of the diaphragm's backing material, which can lead to a loss of sealing capability and eventual diaphragm failure. At extreme temperatures, the bond between the PTFE and its backing can also weaken, causing delamination.

Considerations for Cryogenic Service

At the low end of the spectrum, around -195°C, materials can become brittle. While PTFE performs well at these temperatures, it's crucial to ensure the valve body and bolting materials are also rated for cryogenic service to avoid brittle fracture. Thermal contraction can also affect sealing, making proper installation and torque specifications essential.

How to Apply This to Your Project

Always consult the manufacturer's specific data sheet and P-T curve for the exact valve model you are considering.

- If your primary focus is high-temperature chemical processing: Verify the temperature rating of the entire diaphragm assembly, not just the PTFE liner, and ensure it meets your needs at the required operating pressure.

- If your primary focus is cryogenic service: Confirm that all valve components, especially the metal body, are certified for the target low temperature to prevent material embrittlement.

- If your primary focus is general industrial use: The standard operational range is typically sufficient, but always reference the P-T curve to ensure you have a safe operating margin.

Ultimately, treating the valve as an integrated system, not just a piece of lined pipe, is the key to safe and reliable operation.

Summary Table:

| Component | Role & Temperature Consideration |

|---|---|

| PTFE Liner | Provides chemical inertness; material can withstand up to ~260°C. |

| Diaphragm Backing | Often the limiting factor (e.g., EPDM); typically rated lower than PTFE. |

| Valve Body | Metal body (e.g., stainless steel) must handle thermal expansion/contraction. |

| Operating Pressure | Critical; maximum temperature decreases as pressure increases (check P-T curve). |

Ensure your fluid handling system operates safely and reliably.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure your PTFE-lined valves and systems meet the exact demands of your application, including critical temperature and pressure requirements.

Let's discuss your project's specifications. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How can the susceptibility to creep and cold flow in PTFE washers be addressed? Improve Stability with Filled PTFE or Metal Backing

- How does the operating temperature range of PTFE compare to rubber seals? The Ultimate Guide to Extreme-Temperature Sealing

- How does PTFE's low coefficient of friction affect its machining process? Balancing Clean Cuts with Material Distortion

- How does CNC machining benefit PTFE part production? Achieve Precision, Consistency & Complex Designs

- What industries benefit the most from using PTFE gaskets? Ensure Reliability in Critical Applications

- What industries commonly use PTFE butterfly valves and why? For Superior Chemical Resistance & Purity

- How do PTFE O-rings compare to Teflon O-rings? The Real Difference Between Solid and Encapsulated Designs

- What is the shape and material of the PTFE Lined Spacer? A Guide to Its Round Design and PTFE Benefits