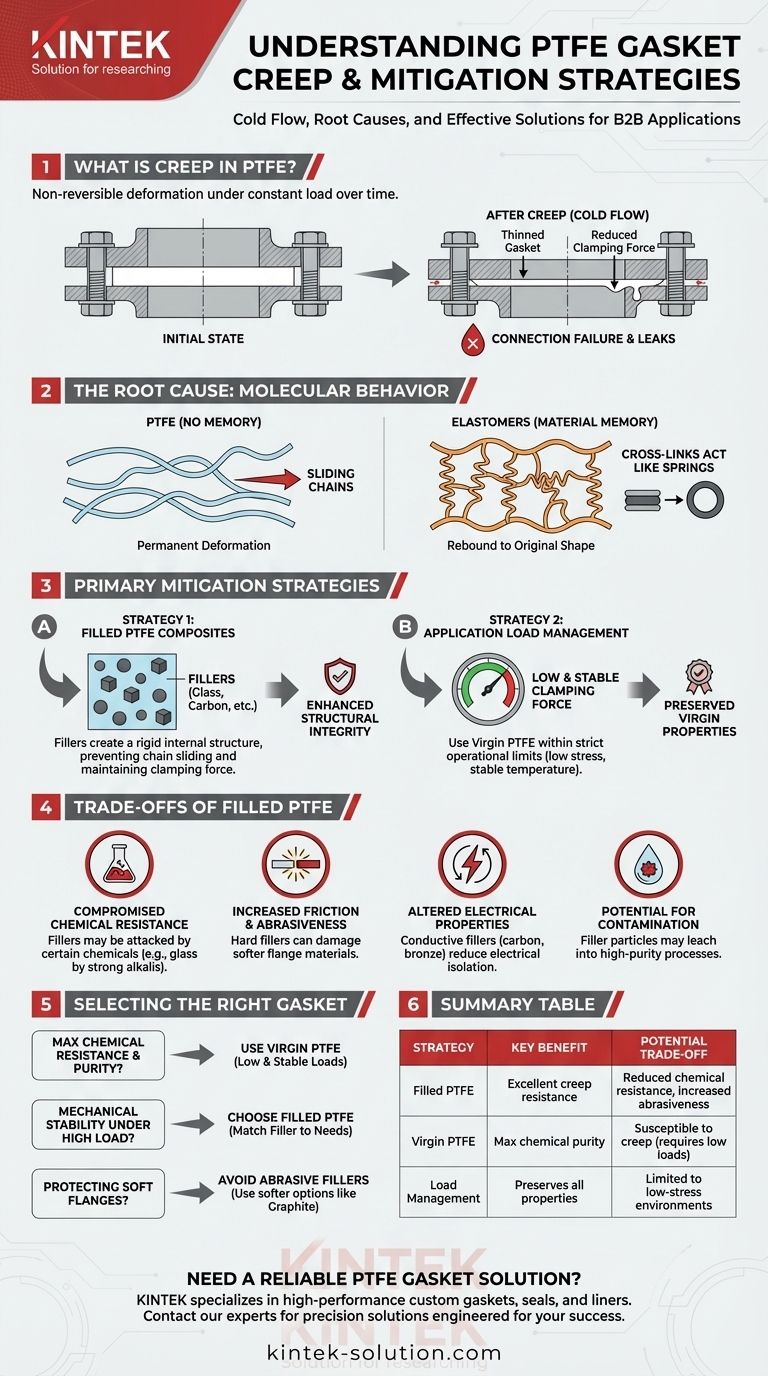

In material science, creep in Polytetrafluoroethylene (PTFE) gasket sheets is a non-reversible deformation that occurs over time when the material is under a constant load. This "cold flow" causes the gasket to thin out, which reduces the clamping force on the flange, ultimately leading to connection failure and leaks. Mitigation involves either controlling the application's load or, more commonly, using filled grades of PTFE that incorporate materials like glass or carbon to enhance structural integrity.

The core challenge with PTFE is that its unique molecular structure, which provides excellent chemical resistance and low friction, also allows it to deform permanently under pressure. The solution is to reinforce this structure with fillers, but this requires a careful trade-off, as these additives can alter the material's original properties.

Understanding the Root Cause: Why PTFE Creeps

To select the right gasket, it's essential to understand why this phenomenon occurs. Unlike many other sealing materials, PTFE has a unique molecular behavior that makes it susceptible to deformation under sustained pressure.

The Problem of "Cold Flow"

Creep in PTFE is often called cold flow. This term describes the material's tendency to slowly and permanently deform or "flow" away from the point of pressure, even at room temperature.

This happens because the long-chain polymer molecules of PTFE are not chemically cross-linked. Under pressure, these chains can slide past one another, and they have no mechanism to return to their original position.

Lack of Material Memory

Elastomers, like rubber, are made of cross-linked molecules. When you compress a rubber O-ring, these cross-links act like springs, storing the energy and allowing the material to rebound to its original shape once the load is removed. This is often called material memory.

PTFE lacks this cross-linking. When it deforms, the change is permanent. This is why a PTFE gasket that has been compressed will not spring back, leading to a loss of sealing force over time.

Primary Strategies for Creep Mitigation

Engineers have developed several effective strategies to counteract PTFE's natural tendency to creep. The choice depends entirely on the demands of the specific application.

Introducing Fillers for Structural Integrity

The most common solution is to create filled PTFE composites. By adding materials like glass, carbon, graphite, or bronze into the PTFE matrix, the creep resistance is significantly improved.

These filler particles provide a rigid internal structure that prevents the PTFE polymer chains from sliding past each other under load. This reinforcement dramatically reduces cold flow and helps maintain the clamping force of the bolted joint.

Managing the Application Environment

In some cases, the best solution is to use virgin (unfilled) PTFE but within strict operational limits. If the application involves very low clamping forces and stable temperatures, the effects of creep may be negligible.

This approach preserves all of PTFE's desirable properties, such as its exceptional chemical resistance and low coefficient of friction, which are often the reasons it was chosen in the first place.

Understanding the Trade-offs of Filled PTFE

While fillers are highly effective at stopping creep, they are not a universal solution. Adding another material to the PTFE matrix fundamentally changes its properties, introducing critical trade-offs that must be considered.

Compromised Chemical Resistance

Virgin PTFE is inert to nearly all industrial chemicals. However, the fillers themselves may not be. For example, glass-filled PTFE is not suitable for strong alkalis or hydrofluoric acid, as these chemicals will attack the glass filler.

Increased Friction and Abrasiveness

One of PTFE's signature features is its extremely low coefficient of friction. Fillers, particularly hard ones like glass or stainless steel, can increase surface friction and make the gasket material more abrasive. This can be a problem for softer flange materials or dynamic sealing applications.

Altered Electrical Properties

PTFE is an excellent electrical insulator with high dielectric strength. Adding conductive fillers like carbon, graphite, or bronze will significantly alter these properties, making the material more conductive and unsuitable for applications requiring electrical isolation.

Potential for Contamination

In high-purity applications such as food processing, pharmaceuticals, or semiconductor manufacturing, filled PTFE can be a source of contamination. The filler particles can potentially leach out or be shed from the gasket material, compromising the process fluid.

Selecting the Right PTFE Gasket for Your Application

Choosing the correct material requires balancing the need for mechanical stability with the other performance requirements of your system.

- If your primary focus is maximum chemical resistance and purity: Use virgin PTFE, but ensure your application operates under low and stable clamping forces to minimize the risk of creep.

- If your primary focus is mechanical stability under high load: Choose a filled PTFE, carefully matching the filler (e.g., glass for general use, carbon for static dissipation) to your system's chemical and thermal demands.

- If your primary focus is protecting soft or sensitive flange surfaces: Avoid abrasive fillers like glass and consider softer options like graphite or specialized filled compounds designed for non-abrasion.

By understanding these material trade-offs, you can select a PTFE gasket that provides a reliable, long-lasting seal without compromising the critical requirements of your system.

Summary Table:

| Mitigation Strategy | Key Benefit | Potential Trade-off |

|---|---|---|

| Filled PTFE (e.g., glass, carbon) | Excellent creep resistance, maintains clamping force | May reduce chemical resistance, increase abrasiveness |

| Virgin (Unfilled) PTFE | Maximum chemical purity and resistance | Susceptible to creep; requires low, stable loads |

| Application Load Management | Preserves all virgin PTFE properties | Limited to low-stress, stable environments |

Need a reliable PTFE gasket solution that balances creep resistance with your specific application needs?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, and liners. Whether you require the chemical purity of virgin PTFE or the enhanced structural integrity of a filled compound for the semiconductor, medical, laboratory, or industrial sectors, our precision production and custom fabrication—from prototypes to high-volume orders—ensure a perfect fit and long-term reliability.

Contact our experts today to discuss your requirements and get a solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some specific applications of PTFE envelope gaskets in industrial equipment? Enhance Sealing Performance and Chemical Resistance

- What are some industrial and niche applications of PTFE coatings? Solve Your Toughest Corrosion and Friction Problems

- What manufacturing facilities are used to produce PTFE wear strips and bands? A Guide to In-House Production

- What temperature range can PTFE O-rings withstand? Unlock Extreme Thermal Performance from -200°C to 260°C

- How can Teflon PTFE sheets assist in crafting with glue or resin? Achieve a Clean, Reusable Workspace

- What factors should be considered when choosing between NBR and PTFE seat materials for butterfly valves?

- How can the mechanical properties of PTFE O-rings be improved? Enhance Strength & Wear Resistance

- What are the main properties of PTFE valve seats in butterfly valves? Ensure Reliability in Harsh Environments