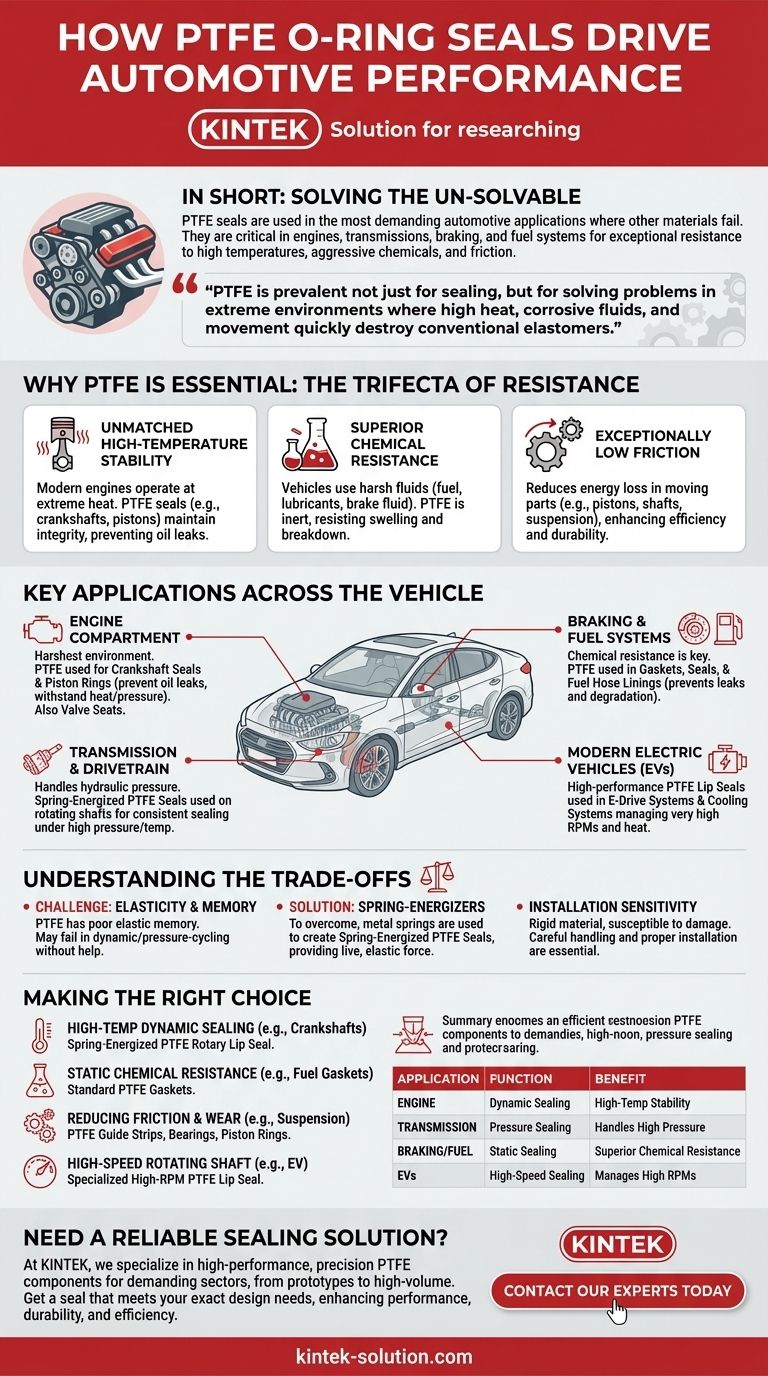

In short, PTFE O-rings and related seals are used in the most demanding automotive applications where other materials would fail. You will find them in critical systems like engines, transmissions, braking, and fuel delivery because of their exceptional resistance to high temperatures, aggressive chemicals, and friction. They are fundamental components for ensuring vehicle performance, preventing fluid leaks, and enhancing long-term reliability.

The core reason PTFE is so prevalent in the automotive industry is not just its sealing ability, but its capacity to solve problems in extreme environments. It provides a reliable seal where high heat, corrosive fluids, and constant movement would quickly destroy conventional elastomers.

Why PTFE is Essential for Automotive Systems

The choice of a sealing material is driven by the operating environment. Automotive systems present a unique combination of high heat, aggressive chemical exposure, and dynamic stress, which is where PTFE (Polytetrafluoroethylene) excels.

Unmatched High-Temperature Stability

Modern engines operate at extremely high temperatures. PTFE seals, especially in engine components like crankshafts and pistons, maintain their structural integrity and sealing capability without degrading, preventing critical oil leaks.

Superior Chemical Resistance

A vehicle utilizes numerous corrosive fluids, including fuel, lubricants, transmission fluid, and brake fluid. PTFE is nearly inert, meaning it will not swell, soften, or break down when exposed to these harsh chemicals, ensuring a longer lifespan for the seal.

Exceptionally Low Friction

In components that move, like pistons, rotating shafts, and suspension parts, friction leads to energy loss and wear. PTFE's remarkably low coefficient of friction minimizes this energy loss, which contributes to overall vehicle efficiency and component durability.

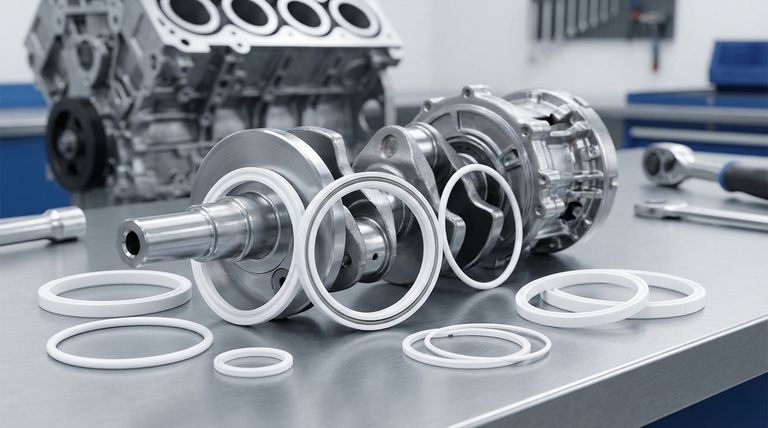

Key Applications Across the Vehicle

While often referred to broadly as "O-rings," the automotive industry uses several forms of PTFE seals, each tailored to a specific function.

In the Engine Compartment

This is the harshest environment in a vehicle. PTFE is used for crankshaft seals and piston rings to prevent oil leaks while withstanding intense heat and pressure. It's also found in valve seats and other components where low friction and high-temperature resistance are critical.

In the Transmission and Drivetrain

Transmissions require robust sealing to manage hydraulic pressure and prevent fluid leaks. Spring-energized PTFE seals are often used on rotating shafts to provide a consistent, effective seal under high pressures and temperature fluctuations.

In Braking and Fuel Systems

PTFE's chemical resistance makes it ideal for sealing systems containing aggressive brake fluid and fuel. It's used in gaskets, seals, and as a fuel hose lining to prevent leaks and component degradation over time.

In Modern Electric Vehicles (EVs)

The material's properties remain critical in the latest vehicle technology. PTFE lip seals are used in e-drive systems and cooling systems that operate at very high speeds, demonstrating their continued relevance in high-performance applications.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE offers elite performance, it's crucial to understand its limitations to apply it correctly.

The Challenge of Elasticity

Unlike rubber elastomers, PTFE has very poor "memory" and is not very elastic. If deformed, it does not spring back into shape easily. This means in dynamic or pressure-cycling applications, a simple PTFE O-ring might fail to maintain a consistent sealing force.

The Role of Energizers

To overcome its low elasticity, PTFE seals are often spring-energized. A metal spring (stainless steel or Elgiloy) is inserted into a groove in the seal. This spring acts as the live, elastic element, constantly pushing the PTFE lips against the sealing surfaces to ensure a reliable seal even under fluctuating conditions.

Installation Sensitivity

Because PTFE is a relatively rigid material, it can be more susceptible to damage during installation than a soft rubber O-ring. A small scratch or nick on the sealing surface can create a leak path, making careful handling and proper installation procedures essential.

Making the Right Choice for Your Application

Selecting the correct type of PTFE seal is critical for achieving your design goal. The specific application dictates the ideal form factor.

- If your primary focus is high-temperature dynamic sealing (e.g., crankshafts): A spring-energized PTFE rotary lip seal is the most reliable choice.

- If your primary focus is static chemical resistance (e.g., fuel system gaskets): Standard PTFE gaskets or specially designed seals offer excellent durability.

- If your primary focus is reducing friction and wear in components (e.g., suspension parts): PTFE guide strips, bearings, or piston rings are engineered for this exact purpose.

- If your primary focus is a high-speed rotating shaft in an EV: A specialized PTFE lip seal designed for high RPMs is necessary to manage heat and maintain contact.

Ultimately, leveraging PTFE correctly is a key enabler of the durability and efficiency expected from modern vehicles.

Summary Table:

| Application Area | Key PTFE Seal Function | Key Benefit |

|---|---|---|

| Engine Compartment | Dynamic sealing for crankshafts, pistons | High-temperature stability, prevents oil leaks |

| Transmission/Drivetrain | Pressure sealing for rotating shafts | Handles high pressure, temperature fluctuations |

| Braking/Fuel Systems | Static sealing for gaskets, linings | Superior chemical resistance, prevents degradation |

| Electric Vehicles (EVs) | High-speed sealing for e-drives, cooling | Manages high RPMs, ensures reliability |

Need a reliable sealing solution for your automotive application?

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a seal that meets the exact demands of your automotive design, enhancing performance, durability, and efficiency.

Contact our experts today to discuss your specific requirements and get a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers