Beyond its renowned chemical inertness, Polytetrafluoroethylene (PTFE) offers a powerful combination of other advantages, most notably an extremely low coefficient of friction, high-temperature resistance, and excellent electrical insulation. These properties make it a uniquely versatile material for demanding mechanical, thermal, and electrical applications where other polymers would fail.

At its core, PTFE's value lies not in a single property, but in the rare synergy of its characteristics. It is a problem-solving material for environments where chemical, thermal, and surface performance demands converge.

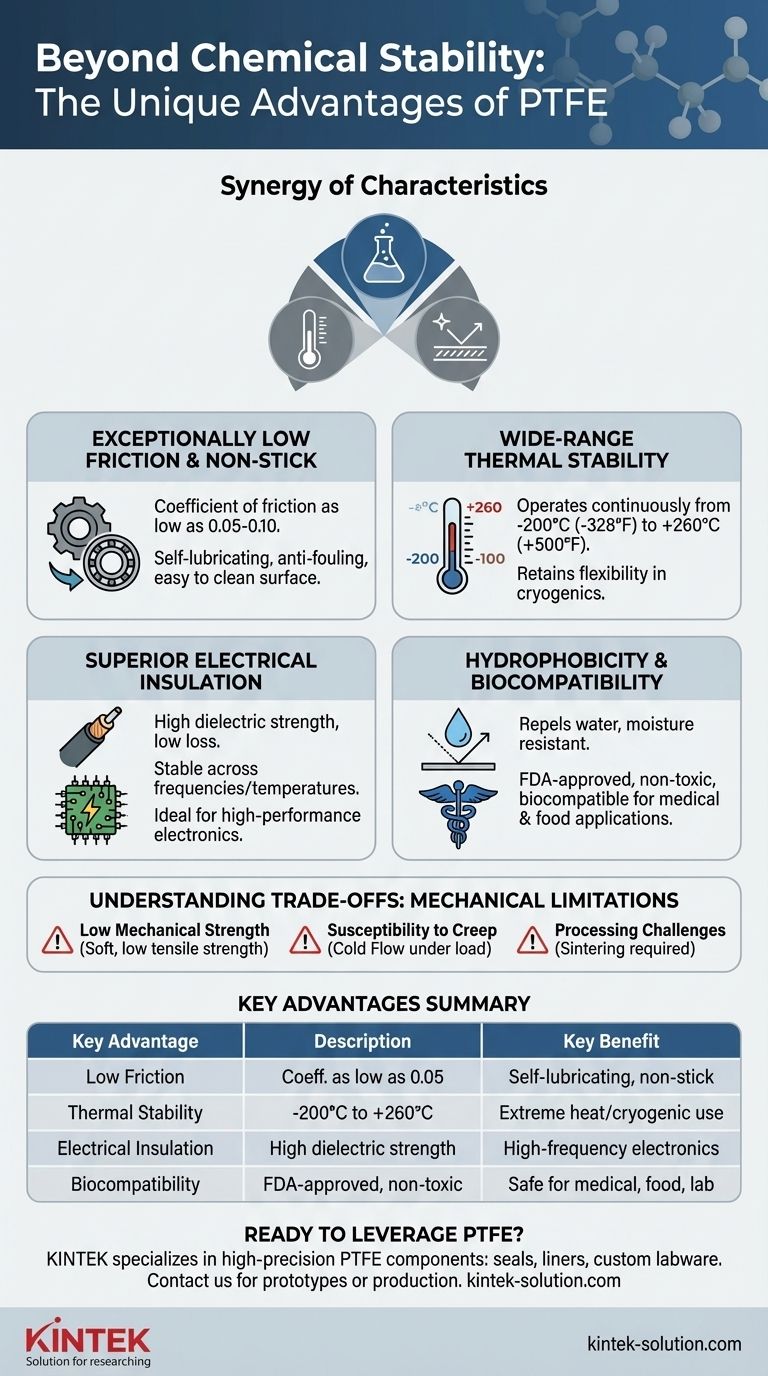

A Deep Dive into PTFE's Performance Characteristics

While chemical stability is its most famous trait, its other features are what enable its use across a vast range of industries. Understanding each one is key to proper material selection.

Exceptionally Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any known solid material, with a value often cited between 0.05 and 0.10. This results in an incredibly slippery, "non-stick" surface.

This property is not just for cookware. It provides excellent self-lubricating performance in mechanical parts like gears, bearings, and slide plates, reducing wear and energy consumption. It also creates an anti-fouling surface that is easy to clean.

Wide-Range Thermal Stability

PTFE exhibits remarkable performance across an exceptionally broad temperature range.

It can operate continuously at temperatures up to +260°C (+500°F) without significant degradation. Equally important, it retains its flexibility and resists embrittlement at cryogenic temperatures as low as -200°C (-328°F).

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with very high dielectric strength and low electrical loss. Its properties remain stable across a wide range of frequencies and temperatures.

This makes it a primary choice for high-performance applications like wire and cable insulation, particularly in coaxial cables and printed circuit boards where signal integrity is critical.

Hydrophobicity and Biocompatibility

The material is hydrophobic, meaning it repels water. This contributes to its ease of cleaning and moisture resistance, which is vital for electrical and medical applications.

Furthermore, virgin PTFE is inherently non-toxic and biocompatible. It is widely approved by the FDA for food contact, making it a standard material in food processing and medical devices.

Understanding the Trade-offs: The Mechanical Limitations

No material is perfect. A trusted advisor must point out the limitations of PTFE to ensure its proper application and avoid design failures.

Low Mechanical Strength

Compared to other engineering plastics like PEEK or Nylon, PTFE is a relatively soft material. It has low tensile strength and is not exceptionally resistant to wear from abrasive materials. Its "slipperiness" is its primary defense against frictional wear.

Susceptibility to Creep (Cold Flow)

Under a sustained compressive load, PTFE has a tendency to deform permanently, a phenomenon known as creep or cold flow. This is a critical design consideration for seals, gaskets, and structural components, as it can lead to a loss of sealing pressure over time.

Processing Challenges

PTFE cannot be processed using conventional melt-processing techniques like injection molding. It is typically shaped through compression and sintering (heating below its melting point until particles fuse), which can be a more complex and costly manufacturing process.

Making the Right Choice for Your Application

Selecting the right material requires balancing its advantages against its limitations in the context of your specific goal.

- If your primary focus is a non-stick, self-lubricating surface: PTFE is an industry-leading choice, especially when chemical or temperature resistance is also required.

- If your primary focus is electrical insulation in extreme environments: PTFE's combination of dielectric strength, thermal stability, and chemical inertness is nearly unmatched.

- If your primary focus is purely mechanical strength and abrasion resistance: A different engineering polymer or a filled grade of PTFE may be a more suitable choice.

- If your primary focus is a food-safe or medical application: The biocompatibility and FDA-compliant grades of PTFE make it a default, trusted option.

Understanding PTFE's full performance profile—not just its chemical resistance—is the key to leveraging its unique capabilities to solve complex engineering challenges.

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Low Friction | Coefficient of friction as low as 0.05 | Self-lubricating, non-stick, easy to clean |

| Thermal Stability | Operates from -200°C to +260°C | Performs in extreme heat and cryogenic environments |

| Electrical Insulation | High dielectric strength, low electrical loss | Ideal for high-frequency and high-temperature electronics |

| Biocompatibility | FDA-approved, non-toxic, hydrophobic | Safe for medical, food processing, and lab applications |

Ready to leverage PTFE's unique properties for your project?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards of performance and reliability.

Contact us today to discuss your specific requirements and discover how our PTFE solutions can solve your complex engineering challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How is PTFE applied in hydrogen energy applications? Ensuring Safety and Efficiency in H2 Systems

- What is PTFE's resistance to fluorine under different conditions? Avoid Costly Failures with Temperature-Specific Data

- What is PTFE's resistance to hydrochloric acid at different concentrations? Discover Unmatched Chemical Inertness

- What makes PTFE difficult to adhere to or weld? Unlocking the Secrets of Teflon® Bonding

- What are the main applications of PTFE? Discover its critical role in chemical, medical, and electronics industries.

- What are the benefits of stainless steel-filled PTFE? Enhance Strength and Temperature Resistance

- How do molybdenum disulfide fillers improve PTFE? Enhance Wear Resistance and Lubricity

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments