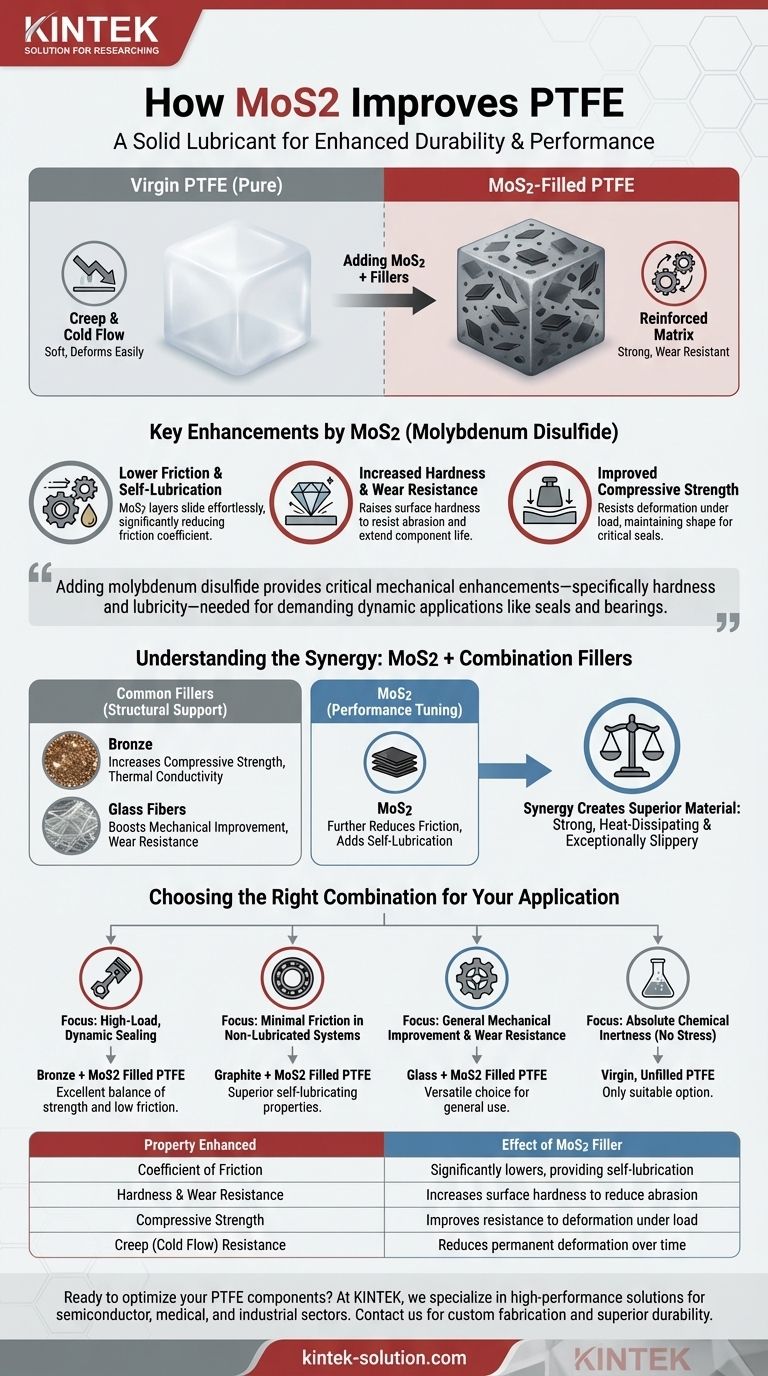

Molybdenum disulfide (MoS2) primarily improves Polytetrafluoroethylene (PTFE) by acting as a solid lubricant. This additive significantly lowers the coefficient of friction while also increasing the material's hardness, compressive strength, and overall wear resistance, making the resulting compound exceptionally durable for moving parts.

While virgin PTFE is famously slippery, it is also soft and deforms easily under pressure. Adding molybdenum disulfide provides the critical mechanical enhancements—specifically hardness and lubricity—needed for demanding dynamic applications like seals and bearings.

Why PTFE Needs Fillers

The Limitations of Virgin PTFE

Pure, or "virgin," PTFE is an extraordinary material known for its extreme chemical inertness and one of the lowest coefficients of friction of any solid.

However, it suffers from poor mechanical properties. It is very soft and exhibits significant "creep" or "cold flow," meaning it slowly deforms over time when subjected to a persistent load.

The Role of a Reinforcing Filler

Fillers are added to PTFE to create a composite material that retains PTFE's low friction while overcoming its mechanical weaknesses.

These additives form a structural matrix within the PTFE, vastly improving properties like wear resistance, compressive strength, and thermal conductivity.

The Specific Contributions of Molybdenum Disulfide (MoS2)

A Potent Solid Lubricant

The primary function of MoS2 is to reduce the coefficient of friction. Its layered, plate-like molecular structure allows these layers to slide against each other with very little force, imparting self-lubricating properties to the PTFE compound.

This makes it highly effective in applications where external lubrication is impossible or undesirable.

Enhanced Hardness and Wear Resistance

By increasing the surface hardness and solidity of the PTFE, MoS2 helps the material better resist abrasion.

Less friction directly translates to less material being worn away during dynamic movement, which significantly extends the service life of components like seals and bearings.

Improved Compressive Strength

The addition of MoS2 particles helps the PTFE matrix resist deformation under load. This is critical for sealing applications, where the material must maintain its shape under pressure to prevent leaks.

Understanding the Key Synergy

MoS2 is Rarely Used Alone

While MoS2 is an excellent lubricant, it does not provide the same degree of bulk structural reinforcement as other common fillers.

For this reason, it is almost always used in combination with other materials, most commonly bronze or glass fibers.

The Power of Combination Fillers

This is where the true value emerges. A filler like bronze dramatically increases compressive strength and thermal conductivity, while MoS2 is added to the same compound to further reduce friction and wear.

This synergy creates a material that is simultaneously strong, heat-dissipating, and exceptionally slippery—a combination that is superior to what any single filler could achieve.

Making the Right Choice for Your Application

By understanding how different fillers contribute, you can select a material tailored to your specific operational demands.

- If your primary focus is high-load, dynamic sealing: Choose a PTFE compound filled with bronze and molybdenum disulfide for an excellent balance of strength and low friction.

- If your primary focus is minimal friction in non-lubricated systems: A compound using graphite and MoS2 will provide superior self-lubricating properties.

- If your primary focus is general mechanical improvement and wear resistance: A glass-filled PTFE, often with MoS2 added for lubricity, is a versatile and common choice.

- If your primary focus is absolute chemical inertness under no mechanical stress: Virgin, unfilled PTFE remains the only suitable option.

Ultimately, viewing molybdenum disulfide as a performance-tuning additive, rather than a bulk filler, is the key to engineering the ideal PTFE component for your project.

Summary Table:

| Property Enhanced | Effect of MoS2 Filler |

|---|---|

| Coefficient of Friction | Significantly lowers, providing self-lubrication |

| Hardness & Wear Resistance | Increases surface hardness to reduce abrasion |

| Compressive Strength | Improves resistance to deformation under load |

| Creep (Cold Flow) Resistance | Reduces permanent deformation over time |

Ready to optimize your PTFE components with the right filler combination? At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components with precisely tuned properties for superior durability and performance. Contact us today to discuss your specific application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main drawbacks of PEEK? Key Limitations for High-Performance Applications

- Is PTFE safe for use in electrical environments? Achieve Superior Insulation & Reliability

- What factors can influence the hardness of PTFE? It's All About the Fillers

- What is the global annual production volume of PTFE? The Scale of a High-Performance Polymer

- What are the emerging market applications for PTFE? Driving Innovation in Semiconductors, EVs, and Medical Tech

- What are the key properties of PTFE? Unlocking Superior Performance for Demanding Applications

- How is PTFE used in food processing applications? Ensuring Hygiene, Efficiency, and Product Integrity

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications