At its core, the materials offered for PTFE bushes are not pure PTFE but specialized compounds designed for specific performance needs. The most common offerings are formulated to be direct equivalents to established industry grades like Rulon 1337 FDA, Rulon 641 FDA, Rulon J, and Rulon LR.

The key is to understand that you are not choosing "PTFE" but a specific blend of PTFE with fillers. This choice is critical because each blend offers a unique combination of wear resistance, chemical compatibility, and load-bearing capabilities.

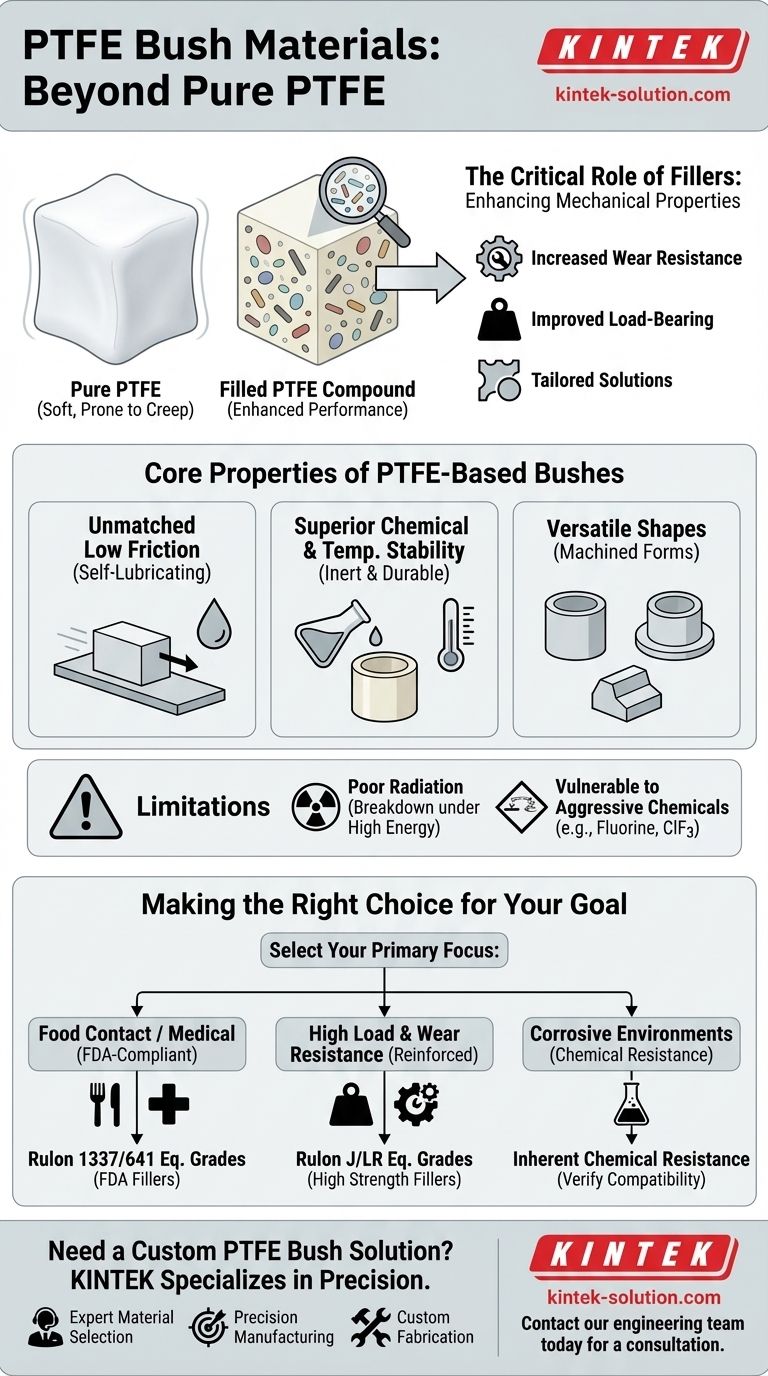

Why "PTFE" is a Family of Materials

The term "PTFE bush" is a starting point. Pure PTFE has excellent low-friction and chemical resistance properties, but it can be soft and prone to deforming under load (a phenomenon known as "creep"). To overcome this, fillers are added to create a range of high-performance compounds.

The Critical Role of Fillers

Fillers are microscopic particles mixed into the base PTFE resin before it's formed. These additives fundamentally enhance the material's mechanical properties without sacrificing its core benefits.

This blending process is what creates distinct material grades, each tailored for different operational demands.

Understanding "Rulon Equivalent"

Rulon is a well-known brand name for a family of high-performance, filled PTFE materials. When a supplier offers a material "equivalent to Rulon J," they are stating that their compound is engineered to match the specific performance characteristics, filler type, and application profile of that industry-standard grade.

Core Properties and Forms

Regardless of the specific blend, all PTFE-based bush materials share a set of powerful advantages that make them suitable for demanding environments.

Unmatched Low Friction

The primary benefit is an exceptionally low coefficient of friction. This results in a self-lubricating surface that minimizes wear on both the bush and the shaft, making it ideal for maintenance-free applications.

Superior Chemical and Temperature Stability

PTFE compounds are chemically inert to most substances, allowing them to operate in highly corrosive environments where metal bushings would fail. They also maintain their integrity across a very wide temperature range.

Versatile Manufacturing and Shapes

These materials are easily machined and can be manufactured in various standard and custom forms. Common shapes include simple cylindrical bushes, flanged bushes for axial load support, and fully custom geometries designed to fit specific assemblies.

Understanding the Trade-offs and Limitations

No material is perfect. To make an informed decision, you must be aware of the inherent limitations of PTFE-based compounds.

Poor Radiation Resistance

PTFE is not suitable for applications involving high-energy radiation. This type of exposure can cause the polymer's molecular structure to break down, leading to a rapid loss of mechanical strength.

Vulnerability to Aggressive Chemicals

While resistant to most chemicals, PTFE can be attacked by highly reactive substances. These include elementary fluorine, chlorine trifluoride, and other powerful fluorinating agents, particularly at high temperatures and pressures.

Naturally Low Adhesion

PTFE has a very low-energy, non-stick surface. While excellent for low-friction applications, this makes it difficult to bond to other materials. If adhesion is required, the surface must undergo special treatments like chemical etching or plasma treatment.

Making the Right Choice for Your Goal

Selecting the correct PTFE compound requires matching the material's specific properties to the demands of your application.

- If your primary focus is food contact or medical use: Seek out FDA-compliant grades, such as those equivalent to Rulon 1337 or Rulon 641.

- If your primary focus is high load and wear resistance: Investigate grades specifically filled to enhance mechanical strength and durability, such as those equivalent to Rulon J or Rulon LR.

- If your primary focus is operation in corrosive environments: The inherent chemical resistance of most PTFE compounds is a major advantage, but always verify compatibility with your specific chemical agents.

Ultimately, choosing the right material is about aligning the unique strengths of a specific PTFE blend with the precise challenges of your engineering problem.

Summary Table:

| Material Grade (Equivalent To) | Primary Filler/Characteristic | Ideal For |

|---|---|---|

| Rulon 1337 / 641 FDA | FDA-compliant fillers | Food contact, medical applications |

| Rulon J | High-load, wear-resistant fillers | High mechanical strength and durability |

| Rulon LR | Low-friction, wear-resistant fillers | General industrial applications |

Need a Custom PTFE Bush Solution?

Selecting the right PTFE compound is critical for performance and longevity. KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and custom labware.

We help engineers in the semiconductor, medical, laboratory, and industrial sectors solve complex challenges by providing:

- Expert Material Selection: Guidance on the optimal filled PTFE grade for your specific needs (e.g., FDA-compliant, high-wear resistance).

- Precision Manufacturing: From prototypes to high-volume orders, ensuring exact specifications are met.

- Custom Fabrication: Tailored solutions for unique geometries and demanding applications.

Let's discuss your project requirements and find the perfect material solution. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE-lined pipes? Achieve Unmatched Corrosion Resistance and Purity

- How do PTFE seals contribute to reducing vehicle emissions? Achieve Cleaner, More Efficient Vehicles

- What are the qualities of PTFE seals? The Key to Reliability in Extreme Conditions

- What are the benefits of regular and preventive maintenance for PTFE butterfly valves? Ensure Long-Term Reliability

- What makes PTFE butterfly valves special compared to other types? Unmatched Chemical & Thermal Performance

- What are the two types of piston seals? Single-Acting vs. Double-Acting Explained

- What are the key advantages of Teflon in anti-corrosion materials? Achieve Unmatched Chemical Resilience

- What are the limitations of machining Teflon? Overcoming Burrs, Creep, and Thermal Instability