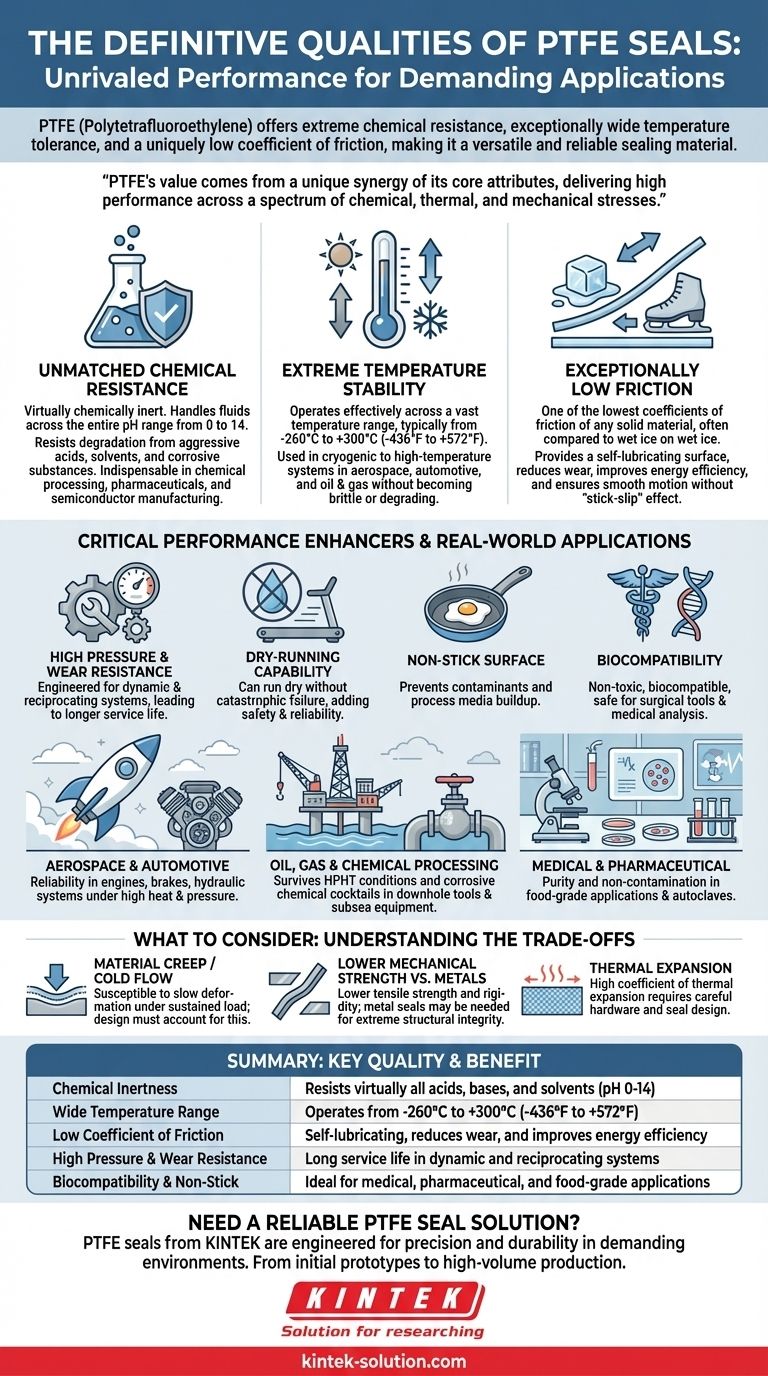

The definitive qualities of PTFE seals are their extreme chemical resistance, exceptionally wide temperature tolerance, and uniquely low coefficient of friction. This combination of properties makes Polytetrafluoroethylene (PTFE) one of the most versatile and reliable sealing materials available, capable of performing in environments where most other materials would quickly fail.

PTFE's value comes from a unique synergy of its core attributes. It doesn't just excel in one area; it delivers high performance across a spectrum of chemical, thermal, and mechanical stresses, making it the default choice for the most demanding sealing applications.

The Fundamental Properties of PTFE Seals

To understand why PTFE is so widely adopted, it's essential to break down its core characteristics. These properties originate from its molecular structure—a strong bond between carbon and fluorine atoms.

Unmatched Chemical Resistance

PTFE is virtually chemically inert. It can handle fluids across the entire pH range from 0 to 14, resisting degradation from aggressive acids, solvents, and corrosive substances.

This makes it indispensable in industries like chemical processing, pharmaceuticals, and semiconductor manufacturing, where seal integrity in the presence of harsh media is non-negotiable.

Extreme Temperature Stability

PTFE seals operate effectively across a vast temperature range, typically from -260°C to +300°C (-436°F to +572°F).

This stability allows them to be used in everything from cryogenic applications to high-temperature systems in aerospace, automotive, and oil and gas exploration without becoming brittle or degrading.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This results in several key performance benefits.

It provides a self-lubricating surface that reduces wear on moving parts, improves energy efficiency, and ensures a smooth transition from standstill to motion without a "stick-slip" effect.

High Pressure and Wear Resistance

While a polymer, PTFE is engineered to maintain its sealing properties in high-pressure applications.

Its inherent toughness and wear resistance make it ideal for dynamic and reciprocating systems, such as those found in hydraulic cylinders and pumps, leading to a longer service life and reduced maintenance costs.

Critical Secondary Characteristics

Beyond the primary qualities, several other features broaden PTFE's utility.

- Dry-Running Capability: Unlike many seals that require lubrication, PTFE can run dry without catastrophic failure, adding a layer of safety and reliability.

- Non-Stick Surface: The material's non-stick nature prevents contaminants or process media from building up on the seal surface, which is critical in food, medical, and pharmaceutical applications.

- Biocompatibility: PTFE is non-toxic and biocompatible, making it a safe and trusted material for surgical tools and medical analysis equipment.

How These Properties Translate to Real-World Applications

The theoretical qualities of PTFE become tangible advantages when applied to specific industrial challenges.

In Aerospace and Automotive

In engines, brakes, and hydraulic systems, seals must withstand high temperatures, high pressures, and constant motion. PTFE's thermal stability and low-friction, wear-resistant nature are essential for ensuring reliability and longevity in these critical components.

In Oil, Gas, and Chemical Processing

This sector demands seals that can survive high-pressure, high-temperature (HPHT) conditions while being exposed to a cocktail of corrosive chemicals. PTFE's chemical inertness is its most valuable asset here, preventing leaks and failures in downhole tools, valves, and subsea equipment.

In Medical and Pharmaceutical

Purity is paramount in medical and food-grade applications. PTFE's biocompatibility, non-toxic nature, and non-stick surface ensure that it will not contaminate the process media, making it ideal for everything from autoclaves to hematology analyzers.

Understanding the Trade-offs

While incredibly capable, PTFE is not a universal solution. As an expert, it's important to recognize its limitations to ensure proper application.

Material Creep or "Cold Flow"

Like many polymers, PTFE can be susceptible to creep, which is a slow deformation under a sustained load. While it performs well under high pressure, designs must account for this tendency to ensure a long-term, stable seal.

Lower Mechanical Strength vs. Metals

Compared to metal seals, PTFE has lower tensile strength and rigidity. In applications requiring extreme structural integrity from the seal itself, a metal or composite seal might be more appropriate.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. This must be factored into the hardware and seal design, especially in systems that experience wide temperature fluctuations, to maintain the correct sealing force.

Making the Right Choice for Your Goal

Selecting a seal material requires matching its properties to your primary operational challenge.

- If your primary focus is reliability in corrosive environments: PTFE's unparalleled chemical inertness makes it the safest and most dependable choice.

- If your primary focus is performance across extreme temperatures: Its vast operating range ensures consistent performance in both cryogenic and high-heat systems.

- If your primary focus is efficiency and long service life in dynamic systems: Its low-friction and wear-resistant properties will minimize energy loss and reduce maintenance cycles.

Ultimately, PTFE's prevalence is a direct result of its ability to solve the most difficult sealing problems where other materials simply cannot perform.

Summary Table:

| Key Quality | Benefit |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents (pH 0-14) |

| Wide Temperature Range | Operates from -260°C to +300°C (-436°F to +572°F) |

| Low Coefficient of Friction | Self-lubricating, reduces wear, and improves energy efficiency |

| High Pressure & Wear Resistance | Long service life in dynamic and reciprocating systems |

| Biocompatibility & Non-Stick | Ideal for medical, pharmaceutical, and food-grade applications |

Need a Reliable PTFE Seal Solution?

PTFE seals from KINTEK are engineered for precision and durability in the most demanding environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your components perform flawlessly.

We specialize in custom fabrication, from initial prototypes to high-volume production, ensuring a perfect fit for your specific application challenges.

Contact KINTEB today to discuss your project and discover how our PTFE components can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance